Dried organic sludge fertilizer and preparation method thereof

A drying sludge and organic fertilizer technology, applied in the field of fertilizers, can solve problems such as difficult to achieve sludge harmless, resourceful and commercialized treatment, refractory, degradable organic matter and pathogen pollution, etc., to achieve rapid drying and Passivation of heavy metal activity, regulation of plant metabolism, and the effects of promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

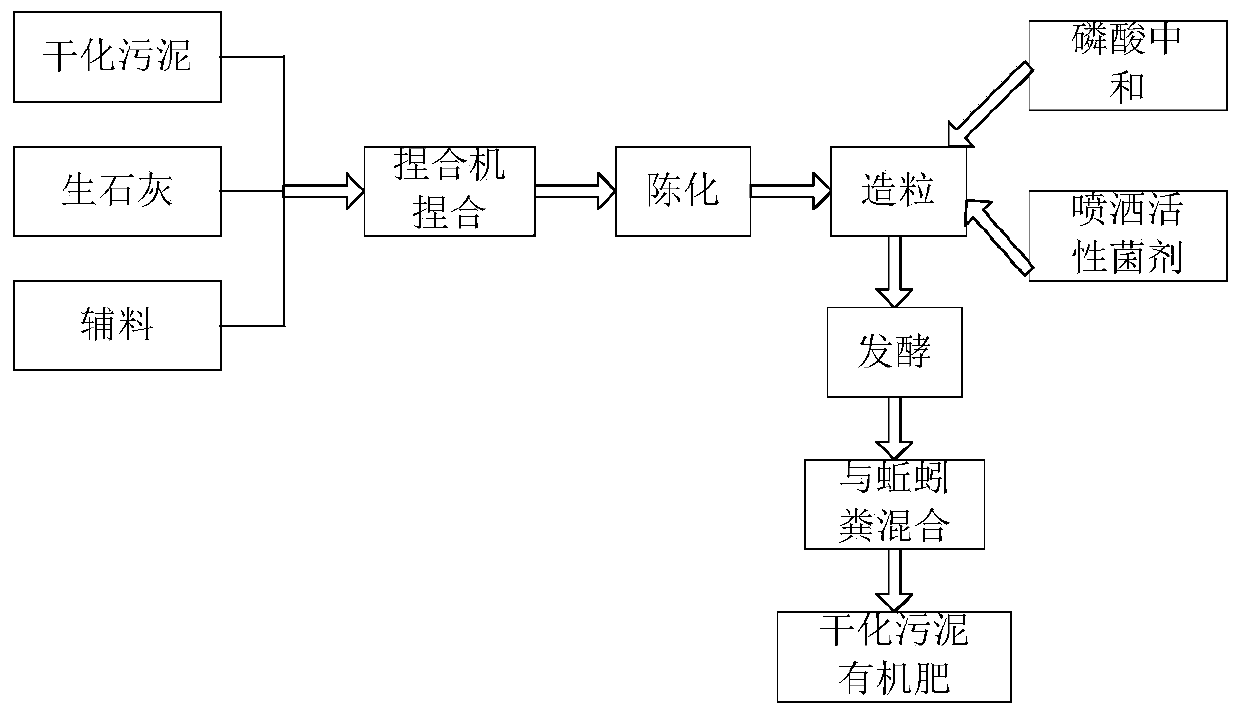

[0026] A kind of preparation method of dried sludge organic fertilizer, such as figure 1 As shown, 1 ton of dried sludge with a moisture content of 30%, 20kg of quicklime, and 200kg of sawdust were put into a kneader and stirred for 30 minutes, then aged at 80°C for 24 hours, and placed in a disc granulator to spray 20kg Phosphoric acid with a concentration of 85% is used for granulation. After stirring evenly, add active bacterial agent according to the inoculation amount of 10kg / t to continue granulation. Put the prepared granules in the fermentation tank for aerobic fermentation for 30 days and mix them with 200kg vermicompost Evenly, the dried sludge organic fertilizer can be obtained.

Embodiment 2

[0028] A kind of preparation method of dried sludge organic fertilizer, such as figure 1 As shown, 1 ton of dried sludge with a moisture content of 40%, 50kg of quicklime, and 200kg of peat were put into a kneader and stirred for 30 minutes, then aged at 60°C for 30h, and sprayed 50kg in a disc granulator. Phosphoric acid with a concentration of 85% is used for granulation. After stirring evenly, add active bacterial agent according to the inoculation amount of 10kg / t to continue granulation. Put the prepared granules in the fermentation tank for aerobic fermentation for 20 days and mix them with 100kg vermicompost Evenly, the dried sludge organic fertilizer can be obtained.

Embodiment 3

[0030] A kind of preparation method of dried sludge organic fertilizer, such as figure 1 As shown, 1 ton of dried sludge with a moisture content of 45%, 70kg of quicklime, and 200kg of peanut meal were put into a kneader and stirred for 30 minutes, then aged at 60°C for 24 hours, and sprayed in a disc granulator. 70kg of phosphoric acid with a concentration of 85% is used for granulation. After stirring evenly, add active bacterial agent according to the inoculation amount of 10kg / t to continue granulation. Put the prepared granules in the fermentation tank for aerobic fermentation for 15 days and mix with 100kg vermicompost Mix evenly to obtain dried sludge organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com