UV light-cured water-based resin and preparation method thereof

A water-based resin, light-curing technology, applied in the field of 3D printing, can solve the problems of human body and environmental threats, safety risks, irritating odor, etc., and achieve the effects of excellent hydrophilicity and mechanical properties, easy cleaning, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

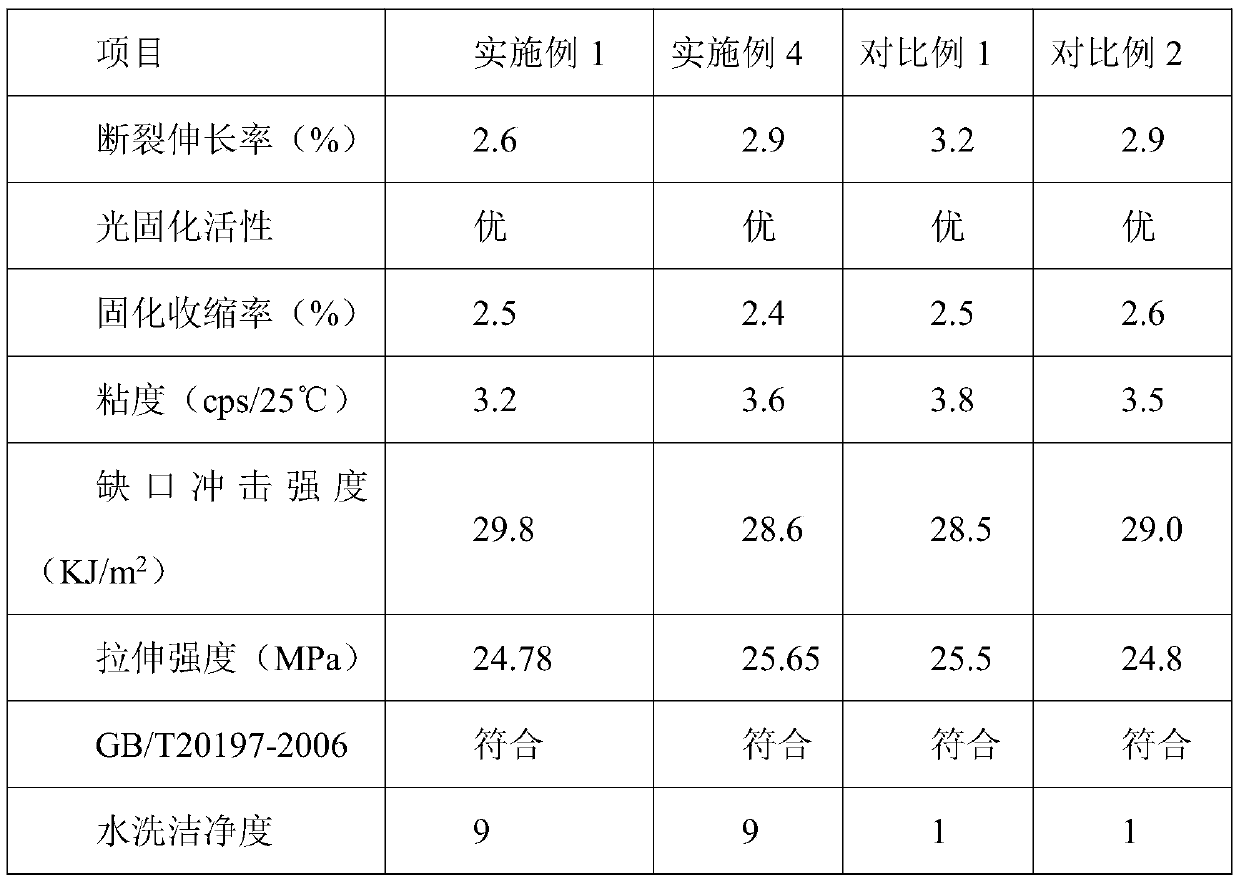

Examples

Embodiment 1

[0019] A UV photocurable water-based resin, comprising the following raw materials: 1 kg of polypropylene oxide ether glycol, 1 kg of polyoxypropylene glycol, 5 kg of isophorone diisocyanate, 0.5 kg of dibutyltin dilaurate, 2,2 - 2 kg of dimethylol propionic acid, 2 kg of hydroxyethyl acrylate, 0.01 kg of p-methoxyphenol, 2 kg of 2,2-dimethyltrimethylene cyclocarbonate, 2 kg of nano-magnesium hydroxide, photosensitive 1 kg of initiator, 10 kg of glycerol dimethacrylate and 10 kg of hexanediol diacrylate.

[0020] The preparation method of described UV photocurable water-based resin, concrete steps are as follows:

[0021] Step 1, taking raw materials according to the proportion, for subsequent use;

[0022] Step 2, mix the raw materials to obtain a mixture, put the mixture into water at 36°C and ultrasonically clean it for 5 minutes with an ultrasonic cleaner, the power of the ultrasonic cleaner is 240W, and the frequency of the ultrasonic waves in the ultrasonic cleaner is 3...

Embodiment 2

[0024] A UV photocurable water-based resin, comprising the following raw materials: 3.6 kg of polypropylene oxide ether glycol, 2.75 kg of polyoxypropylene glycol, 6.1 kg of isophorone diisocyanate, 0.78 kg of dibutyltin dilaurate, 2,2 - 2.6 kg of dimethylolpropionic acid, 2.66 kg of hydroxyethyl acrylate, 0.07 kg of p-methoxyphenol, 2.84 kg of 2,2-dimethyltrimethylene cyclocarbonate, nano-magnesium hydroxide with a particle size of 46nm 4.48 kg, 5.08 kg of cationic photoinitiator, 17.9 kg of glycerol dimethacrylate and 19.4 kg of hexanediol diacrylate.

[0025] The preparation method of described UV photocurable water-based resin, concrete steps are as follows:

[0026] Step 1, taking raw materials according to the proportion, for subsequent use;

[0027] Step 2: Mix the raw materials to obtain a mixture, put the mixture into water and ultrasonically clean it for 10 minutes, and then stir evenly at a speed of 330 rpm to obtain the finished product.

Embodiment 3

[0029] A UV photocurable water-based resin, comprising the following raw materials: 7.45 kilograms of commercially available polypropylene oxide ether glycol, 6.8 kilograms of polyoxypropylene glycol, 8.75 kilograms of isophorone diisocyanate, 1.46 kilograms of dibutyltin dilaurate, 2 , 4.26 kg of 2-dimethylolpropionic acid, 3.94 kg of hydroxyethyl acrylate, 0.14 kg of p-methoxyphenol, 4.45 kg of 2,2-dimethyltrimethylene cyclocarbonate, 6.33 kg of nano-magnesium hydroxide , 8.69 kilograms of photoinitiator, 23.67 kilograms of glycerol dimethacrylate and 26.89 kilograms of hexanediol diacrylate.

[0030] The preparation method of described UV photocurable water-based resin, concrete steps are as follows:

[0031] Step 1, taking raw materials according to the proportion, for subsequent use;

[0032] Step 2, mix the raw materials to obtain the mixture, put the mixture into water at 42°C and ultrasonically clean it with an ultrasonic cleaner for 12 minutes, the power of the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com