Method for producing pyrroloquinoline quinine-containing table vinegar through co-culture and fermentation of microorganisms

A pyrroloquinoline quinone, co-cultivation technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as single method and limited types of nutritional functional factors, and achieve novel methods and increase nutritional health. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

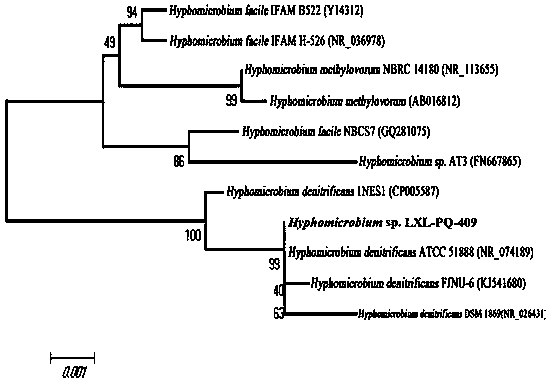

[0021] Embodiment 1: the hyphomicrobe used in this application is the hyphomicrobial LXL-PQ-409, which is specifically obtained through the following steps:

[0022] Isolation of pyrroloquinoline quinone-producing bacteria from Zhejiang rice wine fermented grains. The fermented wine grains were taken, diluted appropriately with sterile physiological saline, and spread on methanol solid medium. Solid medium containing 2% methanol, (NH 4 ) 3 C 6 h 8 o 4 0.3%, KH 2 PO 4 0.14%, Na 2 HPO 4 0.3%, MgSO 4 ·7H 2 O 0.1%, trace element solution 0.07%, agar 2%, and water as the balance, the pH of the medium was 7, the culture temperature was 30°C, and the culture time was 7 days. Then pick out the colonies with better growth and inoculate them in liquid medium (same as solid medium except without agar) for 7 days. After LC / MS analysis and detection, the pyrroloquinoline quinone-producing strains are obtained.

[0023] Take the slant bacteria, add 10 mL of normal saline to m...

Embodiment 2

[0028] (1) Take 10 parts of rice wine mash, 1 part of methanol, and 89 parts of water to prepare Saccharomyces cerevisiae-hybrid microbe culture medium, adjust reducing sugar to 3% w / v, and pH to 7.0. Inoculate the Phytophagia and Saccharomyces cerevisiae for co-cultivation, the inoculum size is 2%, and the culture condition is 32°C for 96 hours. The germination rate of yeast is 98%, and the number of colony-forming units of hyphaetic microbes is greater than or equal to 7.0×10 8 / ml.

[0029] (2) Using rice and water as raw materials, mix them at a ratio of 1:3, add 0.3% α-amylase and 0.3% glucoamylase for amylase saccharification treatment, and add 0.1% CaCl 2 Carry out pulping treatment, add methanol concentration to 1.0% w / v, inoculate Saccharomyces cerevisiae-Rhimephagia seed solution for fermentation, inoculum size 5% v / v, and culture at 30°C for 64 hours to obtain ethanol alcohol base, ethanol Concentration 6% w / v. After fermentation, adjust the concentration of etha...

Embodiment 3

[0033] (1) Take 10 parts of pre-fermented wine mash, 1 part of methanol, and 89 parts of water to prepare Saccharomyces cerevisiae-hybrid microbe culture medium, adjust reducing sugar to 1% w / v, and pH to 6.0. Inoculate Acetobacter-Saccharomyces cerevisiae for co-cultivation at 25°C for 48 hours. The germination rate of yeast is greater than or equal to 85%, and the number of colony-forming units of hyphaetic microbes is greater than or equal to 0.2×10 8 / ml.

[0034] (2) Using rice and water as raw materials, mix them at a ratio of 1:3, add 0.3% α-amylase and 0.3% glucoamylase for amylase saccharification treatment, and add 0.1% CaCl 2 Slurry treatment was carried out, after the concentration of methanol was added to 0.2% w / v, the seed liquid of Saccharomyces cerevisiae-Phyphaeophagic bacteria was inoculated for fermentation, the inoculum amount was 1% v / v, and the temperature was 28°C for 24 hours to obtain ethanol alcohol base. Ethanol concentration 2.5% w / v. After ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com