Production method capable of reducing hot working cracking tendency of Mn18Cr18N retaining ring steel

A production method and thermal processing technology, applied in the direction of metal processing equipment, improvement of process efficiency, improvement of energy efficiency, etc., can solve problems such as high temperature deformation resistance, narrow forgeable temperature range, and influence on yield, and achieve good surface, The effect of high yield and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

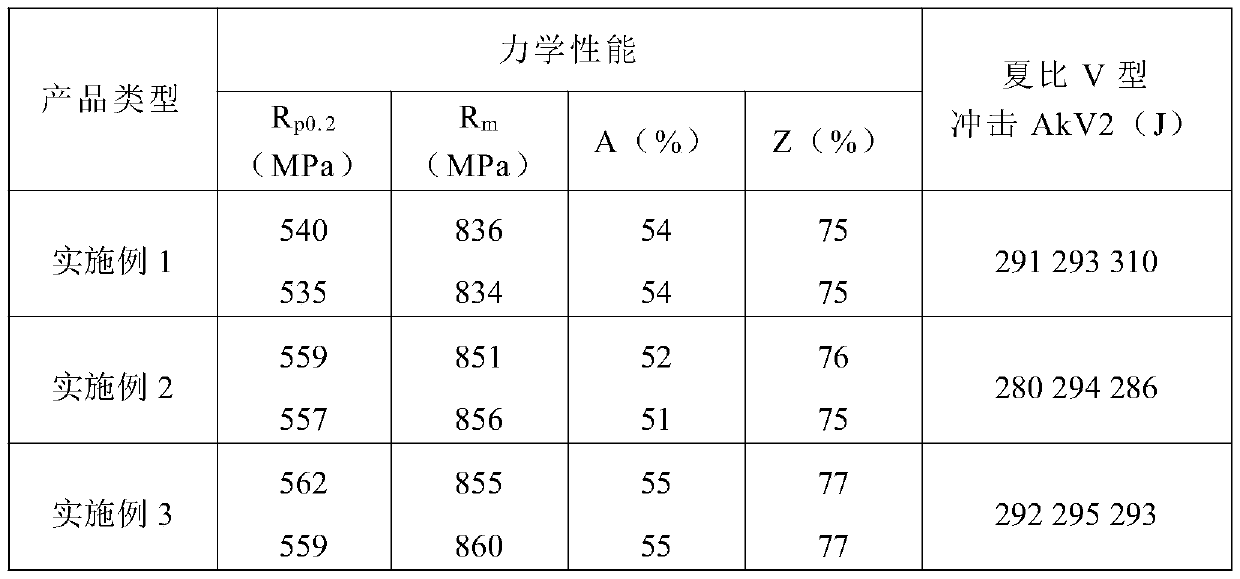

Examples

Embodiment 1

[0028] A Mn18Cr18N retaining ring steel forging, its element composition and mass percentage are as follows: C 0.10%, Si0.80%, Mn 17.5%, Cr 17.5%, Ni 2.0%, N 0.45%, V0.25%, Ti 0.10%, Al 0.04%, P0.060%, S 0.015%, Fe balance.

[0029] The production method of above-mentioned Mn18Cr18N retaining ring steel forging is according to the following steps:

[0030] (1) Smelting: use a non-vacuum induction furnace to smelt Mn18Cr18N retaining ring steel, add a rare earth alloy (lanthanum-cerium alloy, the addition amount is 2‰) along with the flow before the steel is cast, and the casting temperature is controlled at 1450 °C;

[0031] (2) Electroslag remelting: The electroslag remelting slag is CaF according to the mass percentage 2 :Al 2 o 3 :MgO:SiO 2 =63%: 7%: 3%: 13% is equipped, the control current is 7500 ± 300A, the voltage is 55 ± 5V, and the electroslag steel ingot is prepared;

[0032] (3) Steel ingot forging: the heating temperature is 1150°C, the starting forging temper...

Embodiment 2

[0035] A Mn18Cr18N retaining ring steel forging, its element composition and mass percentage are as follows: C 0.08%, Si0.60%, Mn 20.0%, Cr 20.0%, Ni 2.0%, N 0.80%, V 0.22%, Ti 0.09%, Al 0.03%, P0.050%, S≤0.010%, Fe balance.

[0036] The production method of above-mentioned Mn18Cr18N retaining ring steel forging is according to the following steps:

[0037] (1) Smelting: use a non-vacuum induction furnace to smelt Mn18Cr18N retaining ring steel, add a rare earth alloy (lanthanum-cerium alloy, the addition amount is 1‰) along with the flow before the steel is cast, and the casting temperature is controlled at 1540 °C;

[0038] (2) Electroslag remelting: The electroslag remelting slag is CaF according to the mass percentage 2 :Al 2 o 3 :MgO:SiO 2 =86%: 7%: 3%: 4% is equipped, the control current is 7500 ± 300A, the voltage is 55 ± 5V, and the steel ingot is prepared;

[0039] (3) Steel ingot forging: the heating temperature is 1250°C, the starting forging temperature is con...

Embodiment 3

[0042]A Mn18Cr18N retaining ring steel forging, its element composition and mass percentage are as follows: C 0.05%, Si0.65%, Mn 18.5%, Cr 19.0%, Ni 1.8%, N 0.55%, V0.20%, Ti 0.06%, Al 0.030%, P0.045%, S 0.010%, Fe balance.

[0043] The production method of above-mentioned Mn18Cr18N retaining ring steel forging is according to the following steps:

[0044] (1) Smelting: use a non-vacuum induction furnace to smelt Mn18Cr18N retaining ring steel, add a rare earth alloy (lanthanum-cerium alloy, the addition amount is 2‰) along with the flow before the steel is cast, and the casting temperature is controlled at 1510 °C;

[0045] (2) Electroslag remelting: The electroslag remelting slag is CaF according to the mass percentage 2 :Al 2 o 3 :MgO:SiO 2 =82%:10%:5%:3%, control current 7500±300A, voltage 55±5V, prepare steel ingot;

[0046] (3) Steel ingot forging: the heating temperature is 1190°C, the starting forging temperature is controlled at 1080°C, and the final forging temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com