Gasoline-resistant elastic PVC (polyvinyl chloride) material and preparation method and application thereof

A PVC material, gasoline-resistant technology, applied in the polymer field, can solve the problems of loss of use function, the sheath becomes hard and brittle, and the surface of the material changes, and achieves the effects of simple processing, low hardness change, and low raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

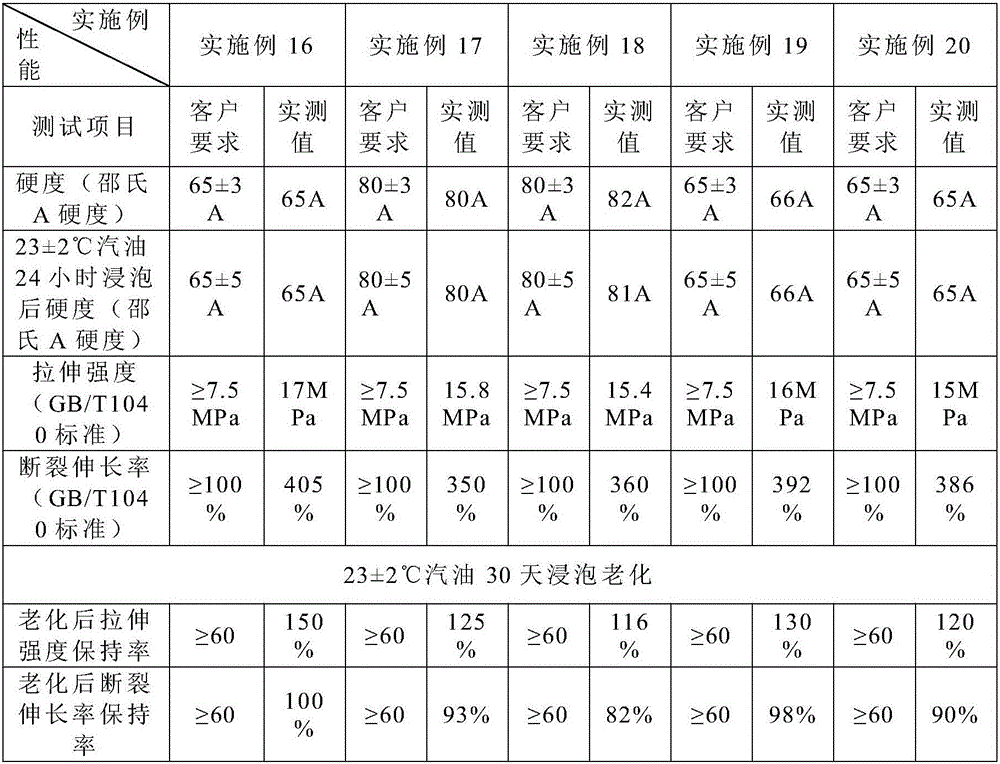

Examples

Embodiment 1

[0032] Preparation of in situ PVC resin:

[0033] The in-situ PVC resin was prepared by the following method: 100 parts of VCM, 140 parts of soft water, 8 parts of modified nano-calcium carbonate, 0.5 parts of composite dispersant, 0.8 parts of initiator, and 3 parts of processing aid were mixed and stirred for 25 minutes, and then the temperature was raised To 70 ℃, when the reaction pressure is reduced to 0.2MPa, the reaction is completed, dehydrated and dried to obtain in-situ PVC resin.

[0034] Wherein, the composite dispersant is a compound mixture of methyl cellulose and hydroxyethyl cellulose in a mass ratio of 1:1.5; A mixture of dialkyl esters; the processing aids include antioxidants, heat stabilizers, anti-ultraviolet absorbers and other common processing aids, which are added according to actual processing.

[0035] Among them, in the modified nano-calcium carbonate, particles with a particle size of 20-80nm account for 75%, and particles with a particle size of ...

Embodiment 2

[0037] Preparation of in situ PVC resin:

[0038] The in-situ PVC resin was prepared by the following method: 100 parts of VCM, 130 parts of soft water, 6 parts of modified nano-calcium carbonate, 0.8 parts of composite dispersant, 0.3 parts of initiator, and 2 parts of processing aid were mixed and stirred for 22 minutes, and then the temperature was raised To 75 ℃, when the reaction pressure is reduced to 0.2MPa, the reaction is completed, dehydrated and dried to obtain in-situ PVC resin.

[0039] Wherein, the composite dispersant is a compound mixture of methyl cellulose and hydroxyethyl cellulose in a mass ratio of 1:1.8; A mixture of dialkyl esters; the processing aids include antioxidants, heat stabilizers, anti-ultraviolet absorbers and other common processing aids, which are added according to actual processing.

[0040] Among them, in the modified nano-calcium carbonate, particles with a particle size of 20-80nm account for 80%, and particles with a particle size of 80...

Embodiment 3

[0042] Preparation of in situ PVC resin:

[0043] In-situ PVC resin was prepared by mixing 100 parts of VCM, 145 parts of soft water, 10 parts of modified nano-calcium carbonate, 0.2 parts of composite dispersant, 1.2 parts of initiator, and 4 parts of processing aids and stirring for 28 minutes, then heating up to 65°C, the reaction is completed when the reaction pressure drops to 0.2MPa, and the in-situ PVC resin is obtained by dehydration and drying.

[0044] Wherein, the composite dispersant is a compound mixture of methyl cellulose and hydroxyethyl cellulose in a mass ratio of 1:1.2; The mixture; said processing aids include antioxidants, heat stabilizers, anti-ultraviolet absorbers and other common processing aids, which are added according to actual processing.

[0045] Among them, in the modified nano-calcium carbonate, particles with a particle size of 20-80nm accounted for 78%, and particles with a particle size of 80-100nm accounted for 22%; and the modified nano-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com