Negative electrode carbon additive for improving charging acceptance of lead-carbon battery and application thereof

A lead-carbon battery and carbon additive technology, used in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of not fully utilizing the characteristics of porous structures, and achieve inhibiting sulfation, prolonging cycle life, and enhancing electrical conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

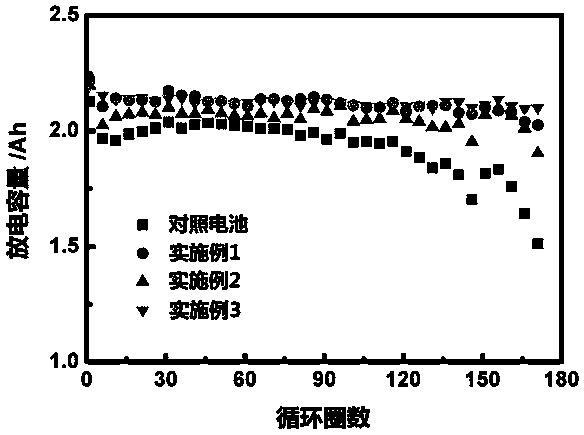

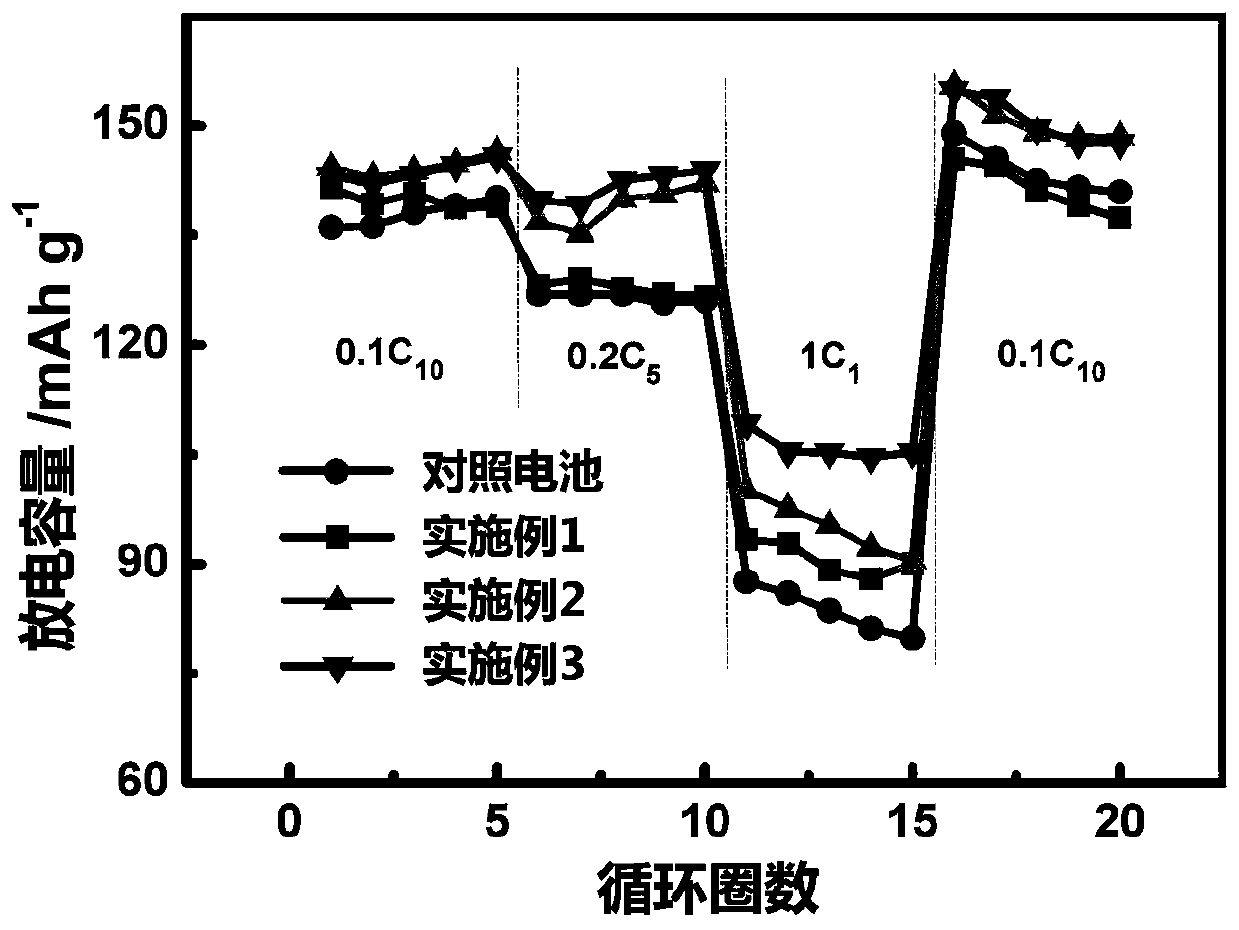

Embodiment 1

[0023] (1) Wash 10 g of rice husk, react in 200 mL, 30 wt.% sodium hydroxide solution at 100° C. for 2 h, filter, wash with purified water, and dry to obtain a desiliconized rice husk;

[0024] (2) After the desiliconized rice husk obtained in the above step (1) is carbonized in a closed environment at 600° C., it is crushed and classified to obtain rice husk-based porous carbon.

[0025] (3) The rice husk-based porous carbon obtained in the above step (2) is directly used as a negative electrode carbon additive to improve the charging acceptance capacity of lead-carbon batteries.

[0026] Weigh 1Kg of lead powder, 1.3g of short fiber, 8g of barium sulfate, 2.5g of humic acid, 2.5g of sodium lignosulfonate, 1.8g of acetylene black and 10g of negative electrode carbon additive to improve the charge acceptance of lead-carbon batteries, and dry mix them 30min, then quickly add 110mL of pure water, stir for 10min, slowly add 60mL of 51.5wt.% sulfuric acid solution and stir for 30m...

Embodiment 2

[0029] (1) Wash 10g of rice husk, react in 200mL, 35wt.% sodium hydroxide solution at 95°C for 1.5h, filter, wash with purified water, and dry to obtain a desiliconized rice husk;

[0030] (2) Carbonize the desiliconized rice husk obtained in the above step (1) in a closed environment at 650° C., and then pulverize and classify to obtain rice husk-based porous carbon.

[0031] (3) The rice husk-based porous carbon and graphite obtained in the above step (2) are uniformly mixed in a ratio of 8:3 to obtain a negative electrode carbon additive that improves the charge acceptance of lead-carbon batteries.

[0032] Weigh 1Kg of lead powder, 1.3g of short fiber, 8g of barium sulfate, 2.5g of humic acid, 2.5g of sodium lignosulfonate, 1.5g of acetylene black and 10g of negative electrode carbon additive to improve the charge acceptance of lead-carbon batteries, and dry mix them After 30min, quickly add 115mL of pure water, stir for 10min, slowly add 57mL of sulfuric acid solution (51...

Embodiment 3

[0035] (1) Wash 10g of rice husk, react in 200mL, 30wt.% potassium hydroxide solution at 90°C for 2.5h, filter, wash with purified water, and dry to obtain a desiliconized rice husk;

[0036] (2) Carbonize the desiliconized rice husk obtained in the above step (1) in a closed environment at 700° C., and then pulverize and classify to obtain rice husk-based porous carbon.

[0037] (3) The rice husk-based porous carbon obtained in the above step (2), conductive carbon black and graphite are uniformly mixed in a ratio of 7:2:3 to obtain a negative electrode carbon additive that improves the charge acceptance of lead-carbon batteries.

[0038] Weigh 1Kg of lead powder, 1.3g of short fiber, 8g of barium sulfate, 2g of humic acid, 2g of sodium lignosulfonate, 1.3g of acetylene black and 12g of negative electrode carbon additives for improving the charge acceptance of lead-carbon batteries, and dry-mix for 30min. Then quickly add 118mL of primary water, stir for 10min, slowly add 58mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com