Hollow bowl-shaped carbon carrier, preparation method thereof, platinum-based catalyst and membrane electrode

A carbon carrier and catalyst technology, applied in the field of fuel cells, can solve the problems of difficulty in mass production, unfavorable mass transfer process, excessive wall thickness, etc., to improve space utilization, improve kinetic activity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the hollow bowl-shaped carbon carrier of the embodiment of the present invention comprises the following steps:

[0042] a. Add tetraethyl orthosilicate to the water-soluble dispersant and mix well;

[0043] b. Add the first component and the second component to the solution of the step a, and the mass ratio of the first component and the second component to the ethyl orthosilicate added in the step a is 1 :(1~4):(10~20), preferably 1:(1~4):(10~15), more preferably 1:(1~3):(10~14), stirring, the reaction produces The precipitation is filtered, washed and dried to obtain a solid product, wherein the first component is selected from one of m-aminophenol, phenol, cresol, xylenol, resorcinol, tert-butylphenol or bisphenol A. kind, preferably m-aminophenol, and the second component is selected from one of formaldehyde, acetaldehyde or furfural, preferably formaldehyde;

[0044] c. Carbonizing the dried solid product in step b under an inert atmosp...

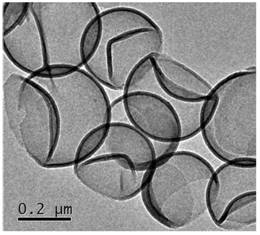

Embodiment 1

[0057] 1. Preparation of carbon support

[0058] 5.5 g of ethyl orthosilicate was dissolved in 20 mL of ethanol, and then added dropwise to a mixed solution consisting of 70 mL of ethanol, 10 mL of ammonia water and 30 mL of water, and stirred uniformly for 1.5 h. Then add 0.5 g of resorcinol and 0.6 g of formaldehyde, that is, the mass ratio of resorcinol: formaldehyde: ethyl orthosilicate is 1:1.2:11, stir at room temperature, and collect the precipitate by centrifugation. The pellet was washed several times. The washed product was dried overnight, and then sent to a rotary tube sintering furnace at a heating rate of 5 °C / min, carbonized at a constant temperature of 700 °C for 5 h in a nitrogen atmosphere, and then switched to carbon dioxide gas, and heated at 10 °C / min. The heating rate was increased to 950°C for 0.5h constant temperature treatment, and the rotation function was started after ventilation, and the rotation rate was 15rpm. Finally, the heat-treated product ...

Embodiment 2

[0063] 1. Preparation of carbon support

[0064] 10 g of ethyl orthosilicate was dissolved in 50 mL of ethanol, and then added dropwise to a mixed solution consisting of 105 mL of ethanol, 15 mL of ammonia water and 60 mL of water, and stirred uniformly for 2 h. Then add 0.8 g m-aminophenol and 1.2 g formaldehyde, that is, the mass ratio of m-aminophenol: formaldehyde: ethyl orthosilicate is 1:1.5:12.5, stir at room temperature, collect the precipitate by centrifugation, and repeat the precipitate with ethanol and deionized water Wash multiple times. The washed product was dried overnight, and then sent to a rotary tube sintering furnace with a heating rate of 3 °C / min, carbonized at a constant temperature of 800 °C for 4 h in a nitrogen atmosphere, and then switched to carbon dioxide gas, and the heating rate was 10 °C / min. The temperature was raised to 1000 °C for 1 h of constant temperature treatment, and the rotation function was activated after ventilation, and the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com