Preparation method and application of absorption material with high absorption capacity

An absorbent material and high-absorption technology, which can be used in absorbent pads, medical science, bandages, etc., can solve problems such as easy-to-contaminate bacteria and mildew, difficulties in mass production, unstable absorption and mechanical properties, etc., to achieve easy construction, product safety, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

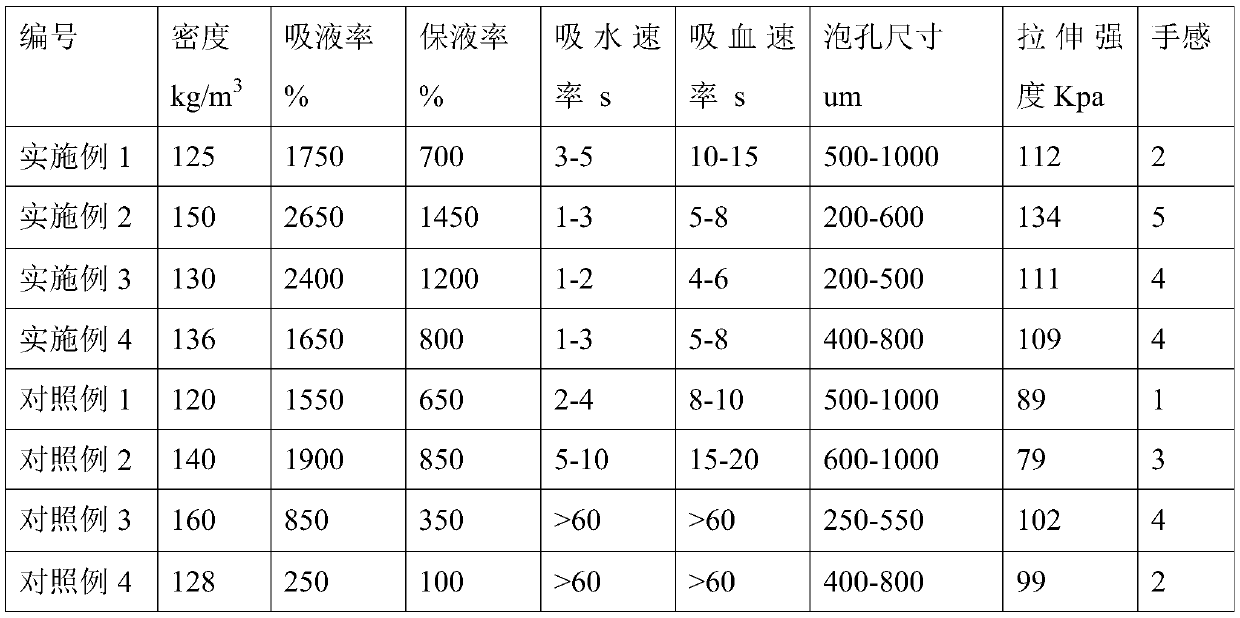

Examples

Embodiment 1

[0072] 1) prepare 75mL concentration of 1wt% 188 aqueous phase solution;

[0073] 2) Add 10 g of superabsorbent polymer with a moisture content of less than 5% to 100 g of isocyanate group-terminated polyurethane prepolymer TP1 WHS-818H, stir and mix at 250rpm;

[0074] 3) Pour all the aqueous phase solution into the above-mentioned polyurethane prepolymer containing superabsorbent polymer quickly, use mechanical stirring at 4000rpm high-speed stirring for 10s, quickly transfer the obtained milky white viscous liquid to the release paper, and put it on the Add another layer of release paper on the surface, wait for 300s, remove the upper and lower layers of release paper, and obtain a composite foam with fixed structure and certain mechanical strength;

[0075] 4) The composite foam obtained in step 3) is dried in a microwave oven for 120 s to remove moisture, and an absorbent material with a cellular structure and high absorption capacity is obtained.

Embodiment 2

[0077] 1) prepare 180mL concentration of 3wt% 182 aqueous phase solution, which contains 0.1wt% ε-polylysine E-PLA;

[0078] 2) Add 50 g of superabsorbent polymer with a moisture content of less than 5% to 100 g of isocyanate group-terminated polyurethane prepolymer TP1 WHS-736, 300rpm slow mixing;

[0079] 3) Pour all the aqueous phase solution into the above-mentioned polyurethane prepolymer containing superabsorbent polymer quickly, use mechanical stirring at 5000rpm high-speed stirring for 5s, quickly transfer the obtained milky white viscous liquid to the release paper, and put it on the Add another layer of release paper on the surface, wait for 300s, remove the upper and lower layers of release paper, and obtain a composite foam with fixed structure and certain mechanical strength;

[0080] 4) Dry the composite foam obtained in step 3) in a hot air oven at 50° C. for 12 hours to remove moisture, and obtain an absorbent material with a cell structure and high absorpti...

Embodiment 3

[0082] 1) Prepare 100 mL of an aqueous phase solution with a concentration of 1 wt% APG0810 and a concentration of methylene blue of 0.015 wt %;

[0083] 2) To 100g isocyanate group-terminated polyurethane prepolymer Add 30g superabsorbent polymer with moisture content below 5% to CST WHS-818H, 250rpm slow stirring and mixing;

[0084] 3) Pour all the aqueous phase solution into the above-mentioned polyurethane prepolymer containing superabsorbent polymer quickly, use mechanical stirring at 4000rpm high-speed stirring for 10s, quickly transfer the obtained milky white viscous liquid to the mold, wait for 200s, and remove from the mold out of the middle, to obtain a composite foam with a fixed structure and a certain mechanical strength;

[0085] 4) The composite foam obtained in step 3) is dried in a microwave oven for 200 s to remove moisture, and an absorbent material with a cell structure and high absorption capacity is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com