Bean dreg pudding and preparation method thereof

A technology for bean dregs pudding and bean dregs, which is applied in the field of food processing, can solve the problems of turning waste into treasure from fresh bean dregs, and achieve the effects of smooth taste, simple formula and natural materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

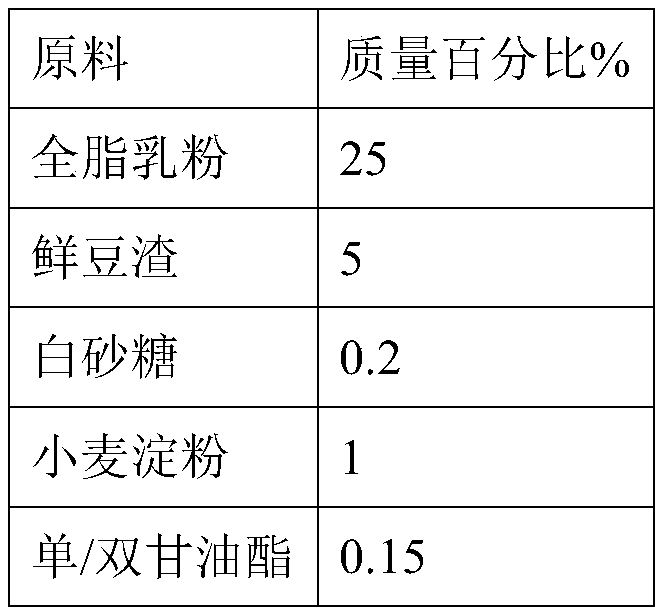

[0031] A kind of okara pudding, the formula is shown in Table 1:

[0032] Table 1

[0033]

[0034]

[0035] The method for preparing the bean dregs pudding includes the following steps:

[0036] (1) Heat the water to 30°C, slowly add the whole milk powder, keep stirring for 60 minutes, and mix evenly to obtain a mixed solution A.

[0037] (2) Mix liquid A with white granulated sugar, wheat starch, mono- and diglycerides, carrageenan, locust bean gum, and edible agar. The mixing temperature is 30°C, and the mixture is kept and stirred for 60 minutes to obtain mixed liquid B.

[0038] (3) Homogenize the mixed solution B, and the homogenization condition is 15MPa and 65°C.

[0039] (4) Add fresh okara into the liquid obtained in step (3) and stir until there are no clumps to obtain a mixed liquid C.

[0040] (5) Sterilize and fill the mixture C, the sterilization conditions are 138℃, 4s; the filling temperature is 60℃, and it will be sealed within 10s after filling;

[0041] (6) Place the se...

Embodiment 2

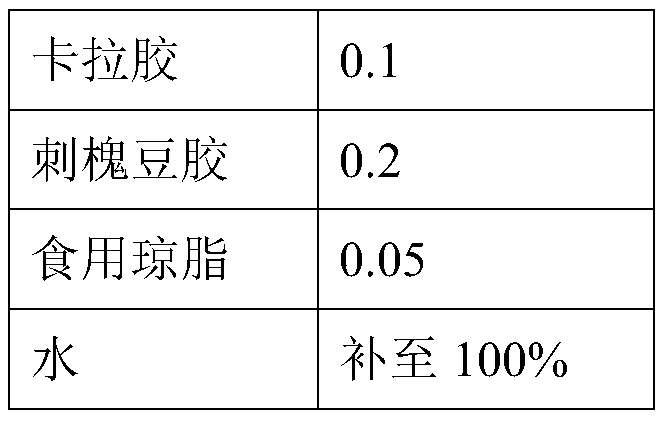

[0043] A kind of okara pudding, the formula is shown in Table 2:

[0044] Table 2

[0045]

[0046]

[0047] The method for preparing the bean dregs pudding includes the following steps:

[0048] (1) Heat water to 50°C, slowly add skimmed milk powder, keep stirring for 20 minutes, mix well, and obtain mixed liquid A.

[0049] (2) Mix liquid A with white granulated sugar, fructose, wheat starch, mono- and diglycerides, carrageenan, locust bean gum, and edible agar at a mixing temperature of 40° C., heat preservation and stirring for 30 minutes to obtain mixed liquid B.

[0050] (3) Homogenize the mixed solution B, and the homogenization conditions are 18MPa and 60°C.

[0051] (4) Add fresh okara into the liquid obtained in step (3) and stir until there are no clumps to obtain a mixed liquid C.

[0052] (5) Sterilize and fill the mixture C, the sterilization condition is 139℃, 3s; the filling temperature is 65℃, and it will be sealed within 10s after filling;

[0053] (6) Place the sealed pr...

Embodiment 3

[0055] A kind of okara pudding, the formula is shown in Table 3:

[0056] table 3

[0057] raw material Mass percentage% Whole milk powder10 Skimmed milk powder5 Fresh Okara15 White sugar5 Hydroxypropyl distarch phosphate5 Mono / Diglycerides0.2 Carrageenan0.15 Locust Bean Gum0.1 Edible agar0.05 water Make up to 100%

[0058] The method for preparing the bean dregs pudding includes the following steps:

[0059] (1) Heat water to 60°C, slowly add whole milk powder and skimmed milk powder, keep stirring for 15 minutes, mix well, and obtain mixed liquid A.

[0060] (2) Mix the mixture A with white granulated sugar, hydroxypropyl distarch phosphate, mono- and diglycerides, carrageenan, locust bean gum and edible agar at a mixing temperature of 50°C, keep it warm and stir for 20 minutes to obtain a mixture B .

[0061] (3) Homogenize the mixed solution B, the homogenization condition is 22MPa, 55°C.

[0062] (4) Add fresh okara into the liquid obtained in step (3) and stir until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com