A method for remediating oil-contaminated soil

A soil remediation and oil-polluted technology, applied in the field of oil-contaminated soil remediation, can solve the problems of long treatment cycle, extraction + biological method limitations, etc., and achieve the effect of convenient material collection, low production process requirements, and simple ultrasonic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for remediating oil-contaminated soil, comprising the following steps:

[0023] (1) Prepare inorganic culture medium: add NH to 100mL UP water 4 Cl 0.776g, KH 2 PO 4 0.05g, K 2 HPO 4 0.05g, CaCl 2 0.001g, MgSO 4 0.01g, adjust the pH to 6-6.5 with HCl (in the inorganic culture medium, the molar ratio of nitrogen-based compounds and phosphorus-based compounds is 10:1);

[0024] (2) production of fermented liquid: add the compound carbon source of 4% mass ratio in inorganic culture liquid, then sterilize at 121 ℃ of high temperature for 20min, inoculate the Pseudomonas aeruginosa of 1.5% (mass volume ratio) after cooling, The number of strains is 1×10 8 ~1×10 9 cells / mL (plate colony counting method), and cultured at a constant temperature for 96 hours at a temperature of 30°C and a rotation speed of 120r / min;

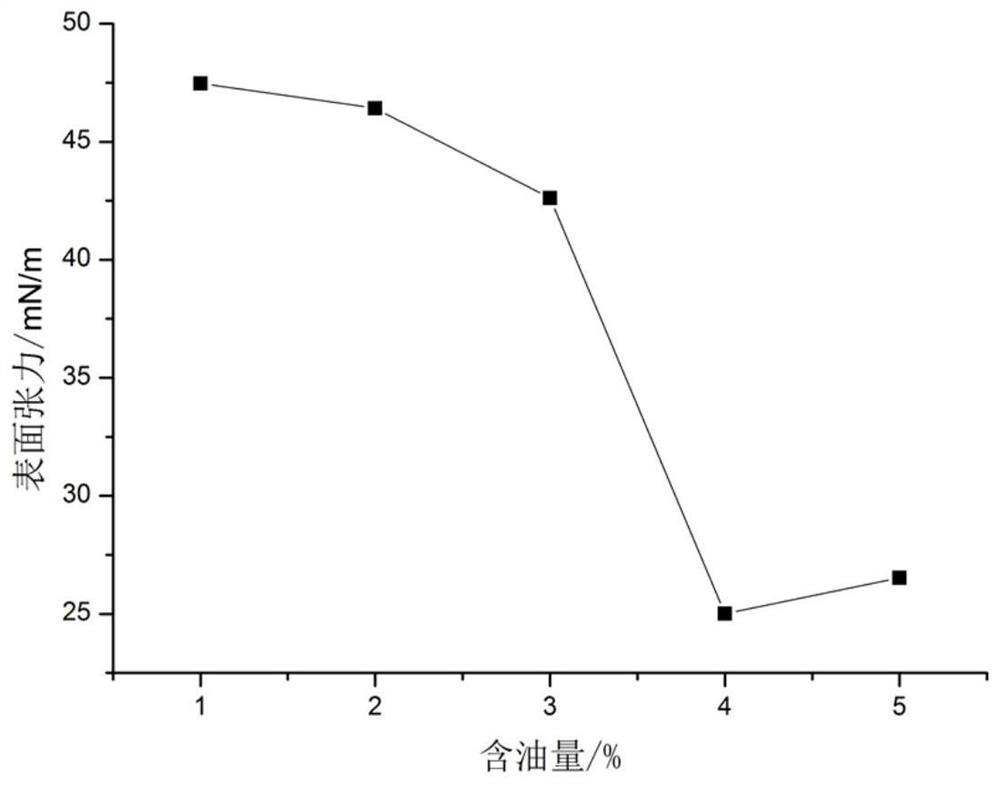

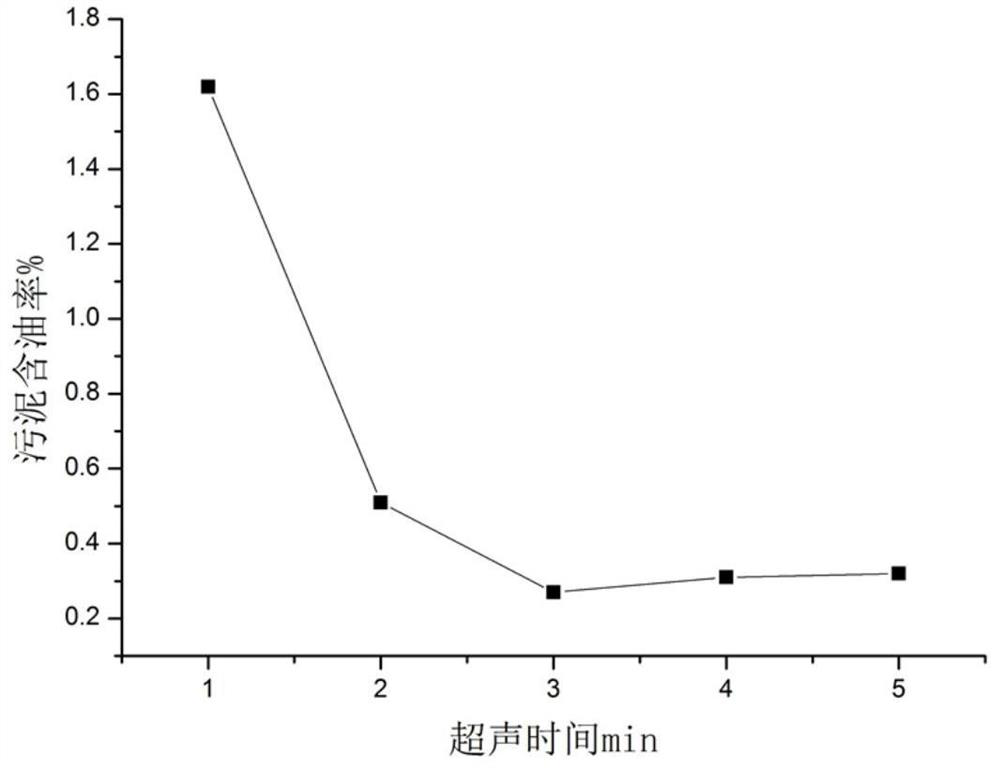

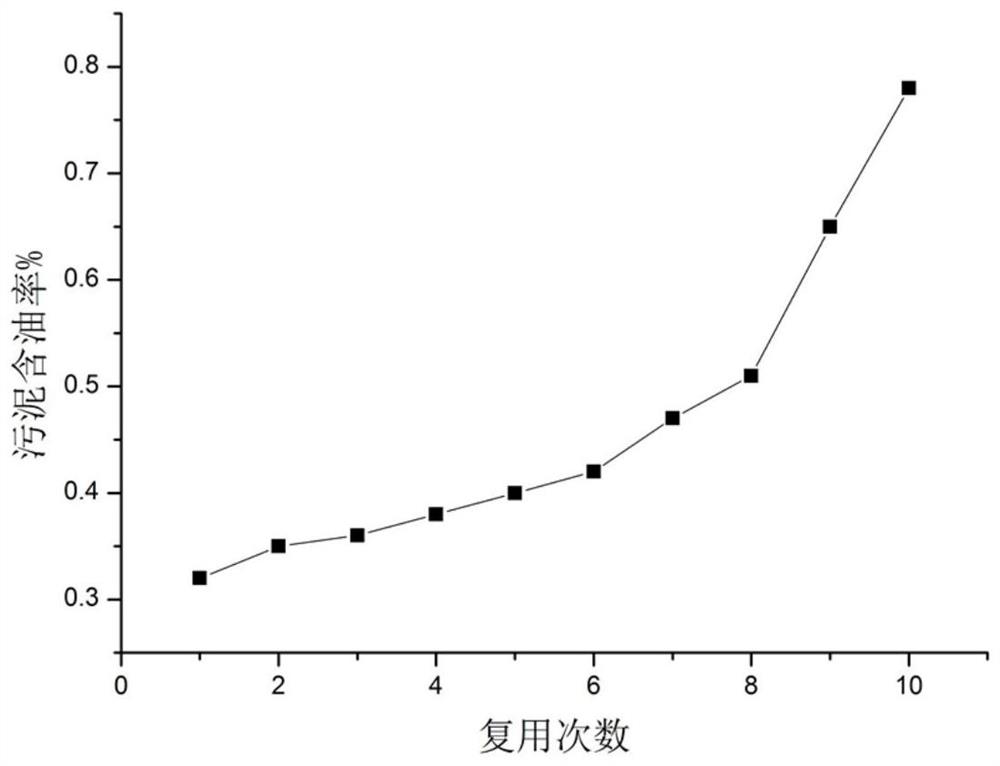

[0025] (3) Prepare cleaning solution: dilute the fermented solution to a mass concentration of 3% with clear water, and adjust the pH to 7-8 w...

Embodiment 2

[0031] A method for remediating oil-contaminated soil, comprising the following steps:

[0032] (1) Prepare inorganic culture medium: add NH to 100mL UP water 4 Cl 0776g, KH 2 PO 4 0.05g, K 2 HPO 4 0.05g, CaCl 2 0.001g, MgSO 4 0.01g, adjust the pH to 6-6.5 with HCl (in the inorganic culture medium, the molar ratio of nitrogen-based compounds and phosphorus-based compounds is 10:1);

[0033] (2) Production of fermented liquid: add 3% composite carbon source in mass ratio to inorganic culture liquid, then sterilize at 121° C. for 20 min, inoculate 1% (mass to volume ratio) of Pseudomonas aeruginosa after cooling, The number of strains is 1×10 8 ~1×10 9 cells / mL (plate colony counting method), and cultured at a constant temperature for 108 hours at a temperature of 30°C and a rotation speed of 120r / min;

[0034] (3) Prepare cleaning solution: dilute the fermented solution to a mass concentration of 5% with clear water, and adjust the pH to 7-8 with NAOH to form a clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com