Modified acrylic resin for automobile paint, preparation method and automobile primer-topcoat paint

A technology of acrylic resin and automotive paint, applied in the direction of coating, etc., can solve the problems such as coating is difficult to meet, achieve strong adhesion, improve high and low temperature resistance and water resistance, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This example provides a modified acrylic resin for automotive paint, the main chain of the modified acrylic resin includes structural units A, B and C;

[0058] The general formula of the structural unit A is:

[0059] where R 1 is a substituent containing at least one hydroxyl group;

[0060] The general formula of the structural unit B is:

[0061] where R 2 Including at least one of a hydrogen atom, a hydroxyl group or an alkyl group;

[0062] In the general formula of the structural unit B, when a dotted line part exists, it represents a naphthyl group; when a dotted line part does not exist, it represents a benzene ring.

[0063] That is, the general formula of structural unit B is:

[0064]

[0065] The general formula of the structural unit C is:

[0066] where R 3 is an alkyl or alkoxy group.

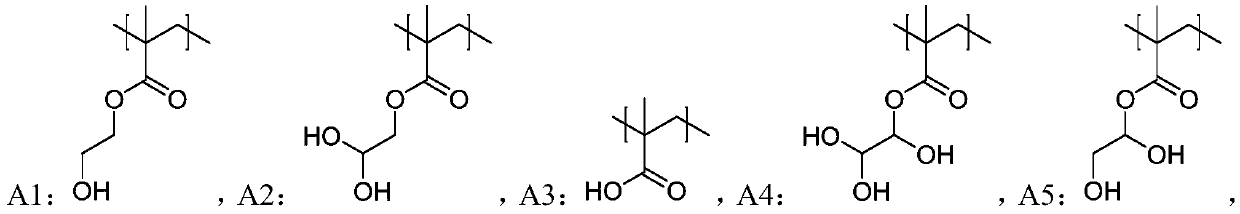

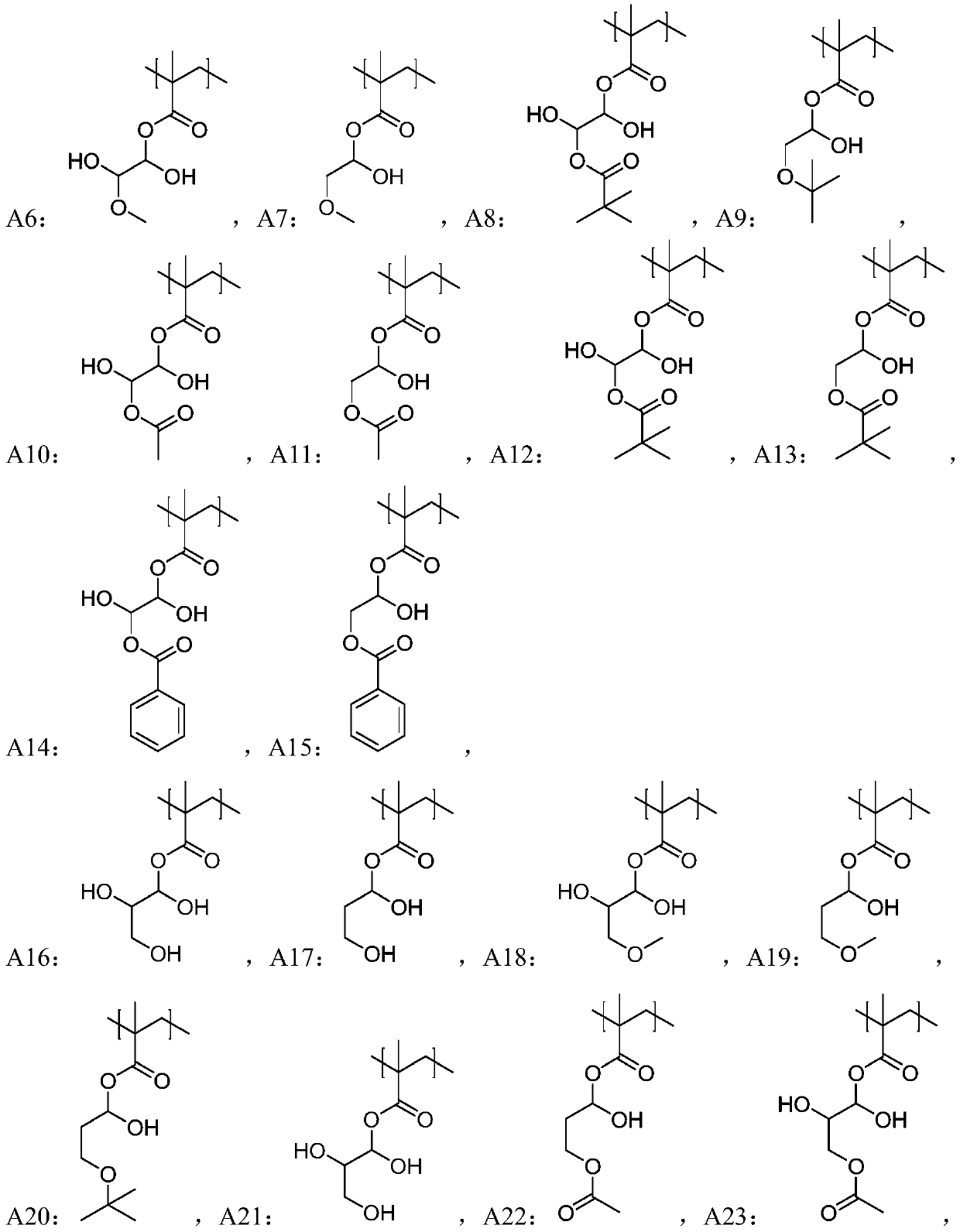

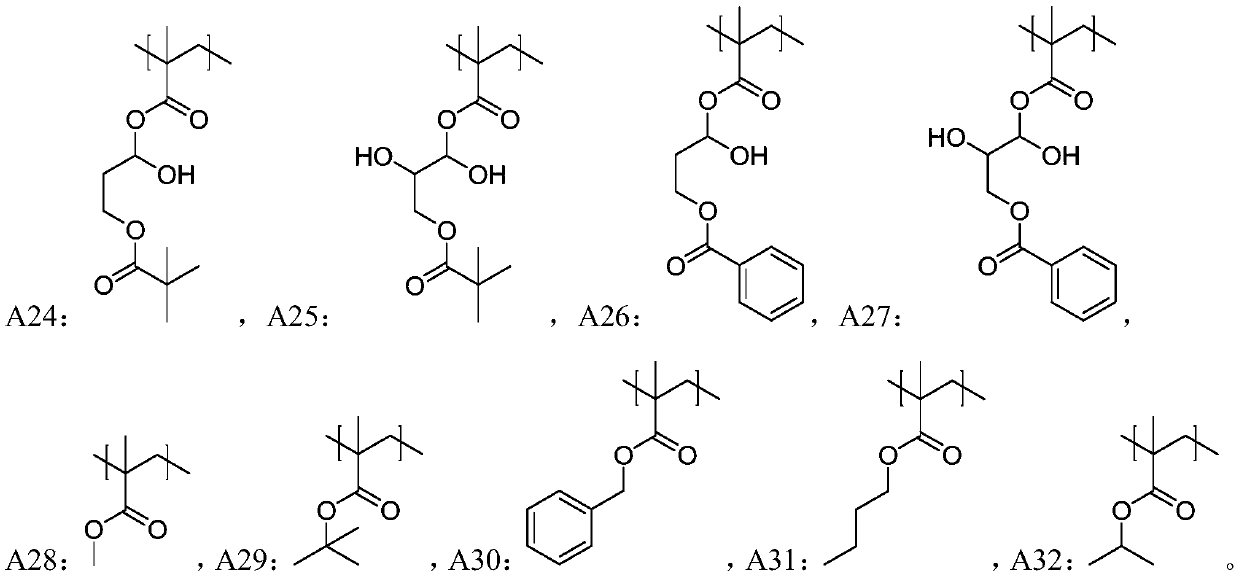

[0067] Preferably, the structural unit A comprises:

[0068]

[0069]

[0070] Preferably, the structural unit B comprises:

[0071]

[0072] ...

Embodiment 2

[0076] This example provides the preparation method of modified acrylic resin for automobile paint, specifically: under the protection of inert gas, add the monomers containing structural units A, B and C into water, then add initiator, emulsifier and toluene to heat and react After the reaction is completed and cooled, the modified acrylic resin for automotive paint is obtained by distillation under reduced pressure.

[0077] When preparing modified acrylic resin for automotive paint, the mass ratio of monomer solution, initiator, emulsifier, toluene and water (100-200): (10-20): (5-10): (10-50): (300~500).

[0078] Wherein, the inert gas is preferably nitrogen, the water is deionized water, the initiator is potassium persulfate, and the emulsifier is OP-10. During preparation, under nitrogen protection, add 10 mL of toluene into the flask and heat to 95°C. Then open the dropping funnel, slowly drop the structural unit solution into the flask, finish dropping within 4 hours...

Embodiment 3

[0080] This example provides a kind of vehicle bottom and surface all-in-one paint, comprises the following components in parts by weight:

[0081] The above-mentioned modified acrylic resin for automobile paint, or 20-30 parts of modified acrylic resin for automobile paint prepared by the above-mentioned preparation method, 20-40 parts of pigment, 0.5-1 part of leveling agent, 0.5-1.0 part of defoamer, 0.5-1.0 parts of anti-settling agent, 1.0-1.5 parts of dispersant, 1.0-1.5 parts of thickener, 0.5-1.0 parts of ultraviolet absorber, 10-20 parts of curing agent, 20-40 parts of water.

[0082] Wherein, the pigment includes titanium dioxide. The leveling agent includes at least one of Wacker HDK@N20, HDK@N20D and HDK@T30. The antifoaming agent includes at least one of DISPERBYK-118 and DISPERBYK-2158. The anti-settling agent is at least one of Elements P200X anti-settling agent and BYK ANTI-TERRA-203. The dispersant is at least one of BYK DISPERBYK-118 or DISPERBYK-2158. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com