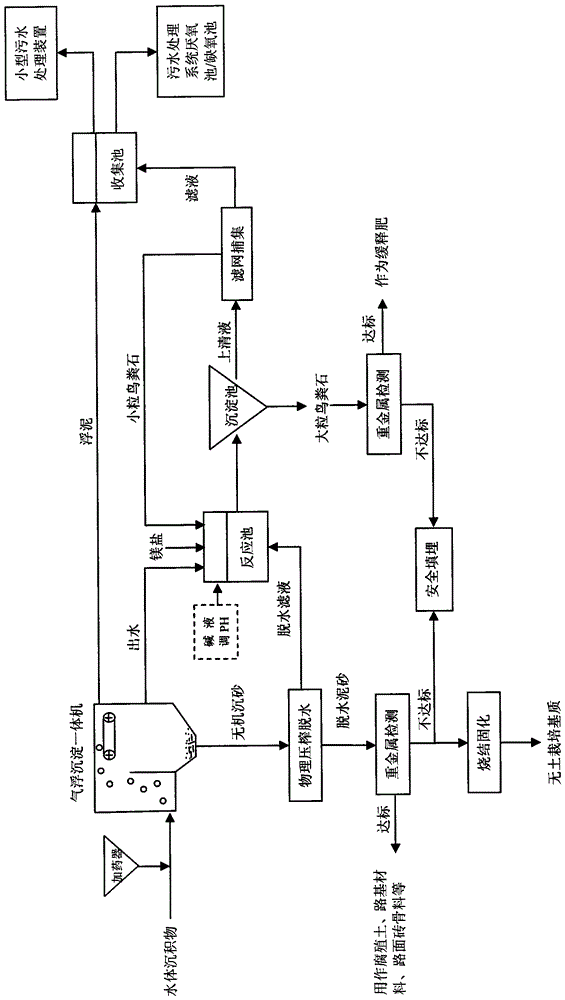

A method for comprehensive utilization of water body sediment reduction and resource utilization

A sediment and resource utilization technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problems of secondary hazards of heavy metals, difficult dehydration of water sediments, low utilization rate of resources, etc. The effect of increasing, increasing the reaction rate and reducing the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The bottom mud taken from a certain reservoir has a moisture content of 94.8%. Sodium hypochlorite solution is added thereto to make the available chlorine content in the bottom mud of the reservoir 2.01 mg / g TSS. The reservoir sediment after dosing is sent to the integrated air flotation and sedimentation machine, and the generated floating mud enters the collection tank, and the sand is dehydrated by physical pressing to obtain decemented sand with a moisture content of 57.6%, and the dewatered filtrate enters the reaction tank. Regularly detect the pH of the water in the air flotation and sedimentation machine. When the pH rises to 8.2, the water is discharged into the reaction tank and mixed with the dehydration filtrate.

[0031] The heavy metal content in the decemented sand was sampled and tested, and the test results are shown in Table 1. The leaching toxicity of heavy metals is up to the standard, and it can be used as humus, roadbed materials or pavement brick ...

Embodiment 2

[0040] The remaining sludge from the municipal sewage treatment plant has a water content of 76.1%, and H2 o 2 Finally, it is sent to the integrated air flotation and sedimentation machine, and the generated floating mud enters the collection tank, and the sand is dehydrated by physical pressing to obtain decemented sand with a moisture content of 38.2%, and the dehydrated filtrate enters the reaction tank. After a period of time, the pH of the water in the air flotation and sedimentation machine rises to 8.5. At this time, the water is discharged into the reaction tank and mixed with the dehydration filtrate.

[0041] The heavy metal content in the decemented sand was sampled and tested, and the test results are shown in Table 3. The leaching toxicity of heavy metals meets the standard, and it can be used as humus, roadbed materials or pavement brick aggregates.

[0042] Measure the concentration of phosphate in the reaction tank to be 376mg / L, add waste brine in the reaction...

Embodiment 3

[0050] The remaining sludge taken from an industrial sewage treatment plant has a moisture content of 87.5%, according to 3kg / m 3 After the amount of sludge is added to potassium ferrate, it is sent to the integrated air flotation and sedimentation machine, and the generated floating mud enters the collection tank, and the sand is dewatered by physical pressing to obtain decemented sand with a moisture content of 43.4%, and the dewatered filtrate enters the reaction tank. After a period of time, the pH of the water in the air flotation and sedimentation machine rises to 8.0. At this time, the water is discharged into the reaction tank and mixed with the dehydration filtrate.

[0051] The heavy metal content in the decemented sand was sampled and tested, and the test results are shown in Table 5. The leaching toxicity of heavy metals meets the standard, and it can be used as humus, roadbed materials or pavement brick aggregates.

[0052] Measure the concentration of phosphate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com