Thermoplastic polyurethane elastomer for mining sieve as well as preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of thermoplastic polyurethane, can solve the problems of humid use environment, increased screen working temperature, accelerated material aging, etc., to achieve extended service life, excellent wear resistance, efficient and stable processing methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

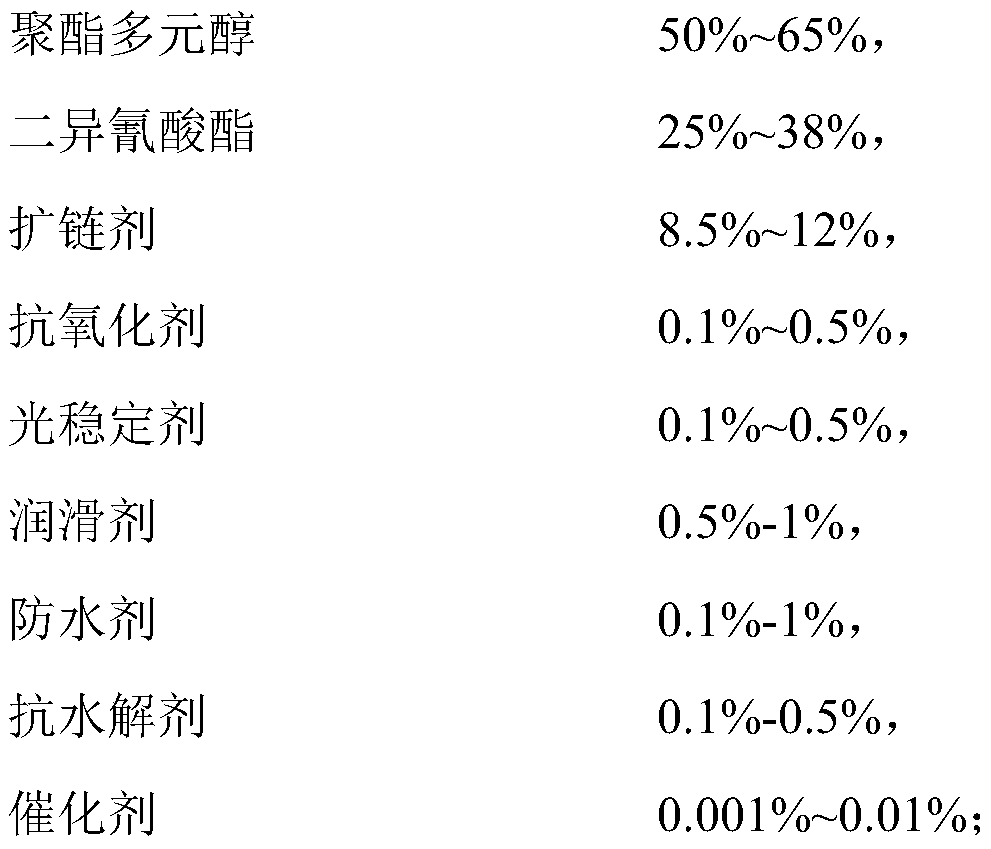

[0030] The thermoplastic polyurethane elastomer for the mine screen is made of the following raw materials in percentage by weight:

[0031]

[0032] The polybutylene adipate / propylene glycol ester diol has a molecular weight of 1000 and a functionality of 2.005.

[0033] The preparation process of the thermoplastic polyurethane elastomer for the mine screen is as follows:

[0034] Mix and heat polybutylene adipate / propylene glycol ester diol, 1010, 770, UV-1, montan wax, polyethylene wax, SF8427, P200 and T-9 to 110±5°C and mix well; MDI -100 is heated to 70±5°C; 1,6-hexanediol is heated to 65±5°C; the heated raw material components are accurately metered and mixed into the tray, and the mixed material enters the high-temperature drying tunnel with the tray, and enters the Aged in a drying room at 100°C for 10 hours, pulverized by a pulverizer, and pelletized underwater by a twin-screw extruder to obtain the product.

Embodiment 2

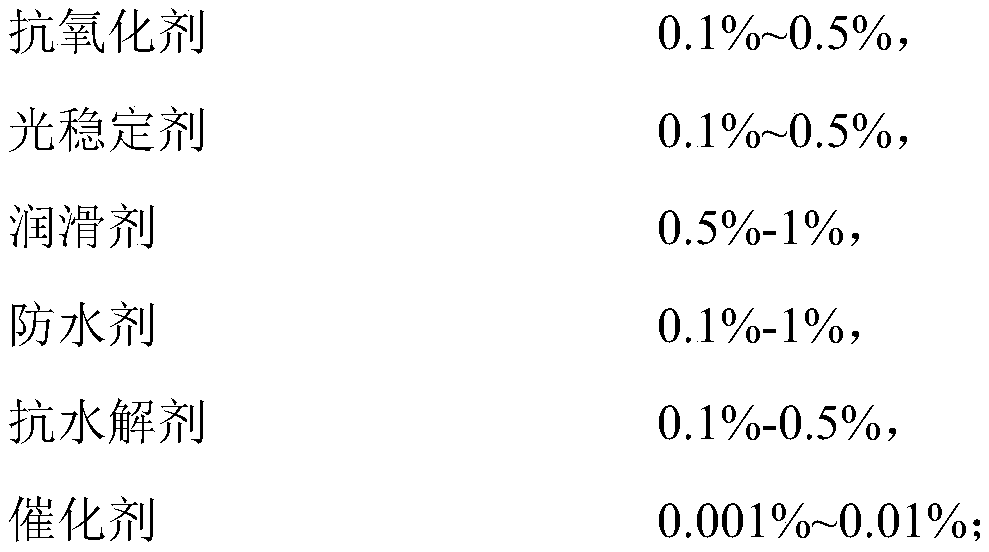

[0036] The thermoplastic polyurethane elastomer for the mine screen is made of the following raw materials in percentage by weight:

[0037]

[0038] The polyhexamethylene adipate / propylene glycol ester diol has a molecular weight of 3000 and a functionality of 2.01.

[0039] The preparation process of the thermoplastic polyurethane elastomer for the mine screen is as follows:

[0040] Mix and heat polyhexamethylene adipate / propylene glycol ester diol, 1010, 770, UV-1, montan wax, polyethylene wax, SF8427, P200 and T-9 to 110±5°C and mix well; MDI -100 is heated to 70±5°C; 1,6-hexanediol is heated to 65±5°C; the heated raw material components are accurately metered and mixed into the tray, and the mixed material enters the high-temperature drying tunnel with the tray, and enters the Aged in a drying room at 100°C for 10 hours, pulverized by a pulverizer, and pelletized underwater by a twin-screw extruder to obtain the product.

Embodiment 3

[0042] The thermoplastic polyurethane elastomer for the mine screen is made of the following raw materials in percentage by weight:

[0043]

[0044] The polyethylene adipate / propylene glycol has a molecular weight of 2000 and a functionality of 2.002.

[0045] The preparation process of the thermoplastic polyurethane elastomer for the mine screen is as follows:

[0046] Mix and heat polyethylene adipate / propylene glycol, 1010, 770, montan wax, polyethylene wax, SF8427, P200 and T-9 to 110±5°C and mix well; heat MDI-100 to 70±5°C; 1,4-butanediol is heated to 65±5°C; the heated raw material components are accurately metered and mixed into the tray, and the mixed material enters the high-temperature drying tunnel with the tray and enters the 100°C drying room Aging for 10 hours, pulverized by a pulverizer, and underwater pelletized by a twin-screw extruder to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com