A building sprinkler system

A sprinkler system and building technology, applied in air conditioning systems, separation methods, heating methods, etc., can solve the problems of inflexible ventilation, unhealthy workers, turbid air, etc., and achieve low maintenance costs, low cycle costs, Fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

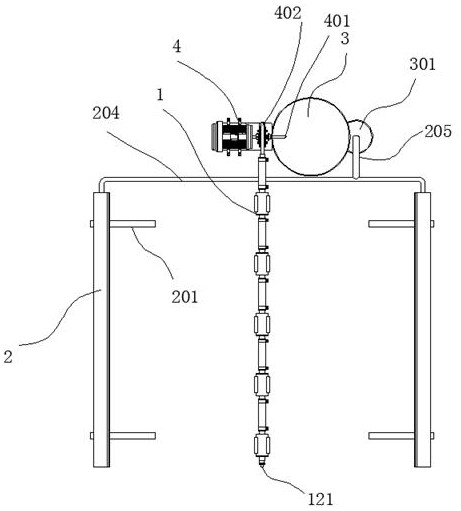

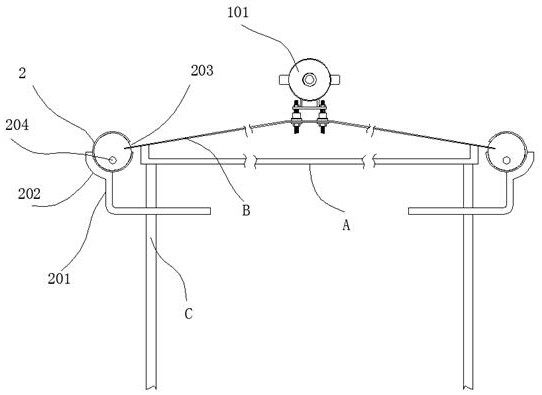

[0042] refer to Figure 1 to Figure 7 As shown, a sprinkler system for a building is shown, which includes a water distribution device 1 arranged at the top of the factory building, return water pipes 2 arranged at the left and right sides of the factory building A, and a storage tank for storing water. Water tank 3, and a vane pump 4 that provides power;

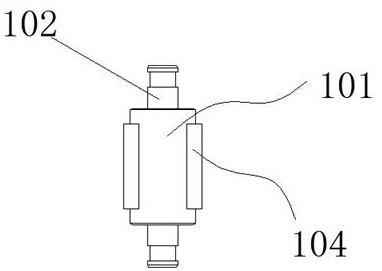

[0043] The water distribution device 1 includes a plurality of pipe fittings 101 connected in series, the front and rear ends of the pipe fittings 101 are injection molded with connecting pipes 102, and rubber hoses 103 are installed between adjacent two pipe fittings 101, and the connecting pipes 102 are inserted into In the rubber hose 103, two water outlets 104 are arranged on the outer wall of the pipe fitting 101, and a plurality of water outlet holes 105 are horizontally arranged on the end surface of the water outlet 104, and the water outlet holes 105 are located in the pipe fitting. On the diameter line of 101, a ...

Embodiment 2

[0047] refer to Figure 8 As shown, the bottom of the pole 201 is screwed with a negative pressure fan 6, one end of the negative pressure fan 6 is located in the factory building, and this end is used for air intake, and the other end of the negative pressure fan 6 is flanged. It is connected with an air guide pipe 7, and after the end of the air guide pipe 7 away from the negative pressure fan 6 extends upward, it is then inclined downward and welded with the return pipe 2; the above structure is mainly to realize the In the working environment of large dust, it is necessary to maintain ventilation in the factory building and exhaust the particulate matter in the factory building to the outside, but direct discharge will inevitably cause pollution to the surrounding environment, so we use a negative pressure fan to extract the dust from the factory building. The air with particles is sent into the return pipe, and there is always water recovered from the ceiling in the retur...

Embodiment 3

[0050] refer to Figure 9 As shown, a filter material 333 is provided in the return tank 301, and a spherical recess 334 is formed after the upper end of the filter material 333 is sunken, and the first conduit 205 is located in the recess 334; in the use of the factory building, The surface of the ceiling will inevitably be covered with dust particles, and the water flow will wash down such dust particles. The dust particles will first enter the return tank, and then return to the water storage tank after being filtered by the filter material. The filter material can be replaced. Easy to maintain.

[0051] The filter material 333 is filter cotton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com