Flexible three-dimensional layered MXene@indium composite film and preparation method and application thereof

A composite film, layered technology, applied in electrode manufacturing, structural parts, electrical components, etc., can solve the problems of reducing lithium metal battery capacity, shortening battery life, SEI film damage, etc., to reduce deposition dissolution overpotential, Improves uniformity and reduces nucleation barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

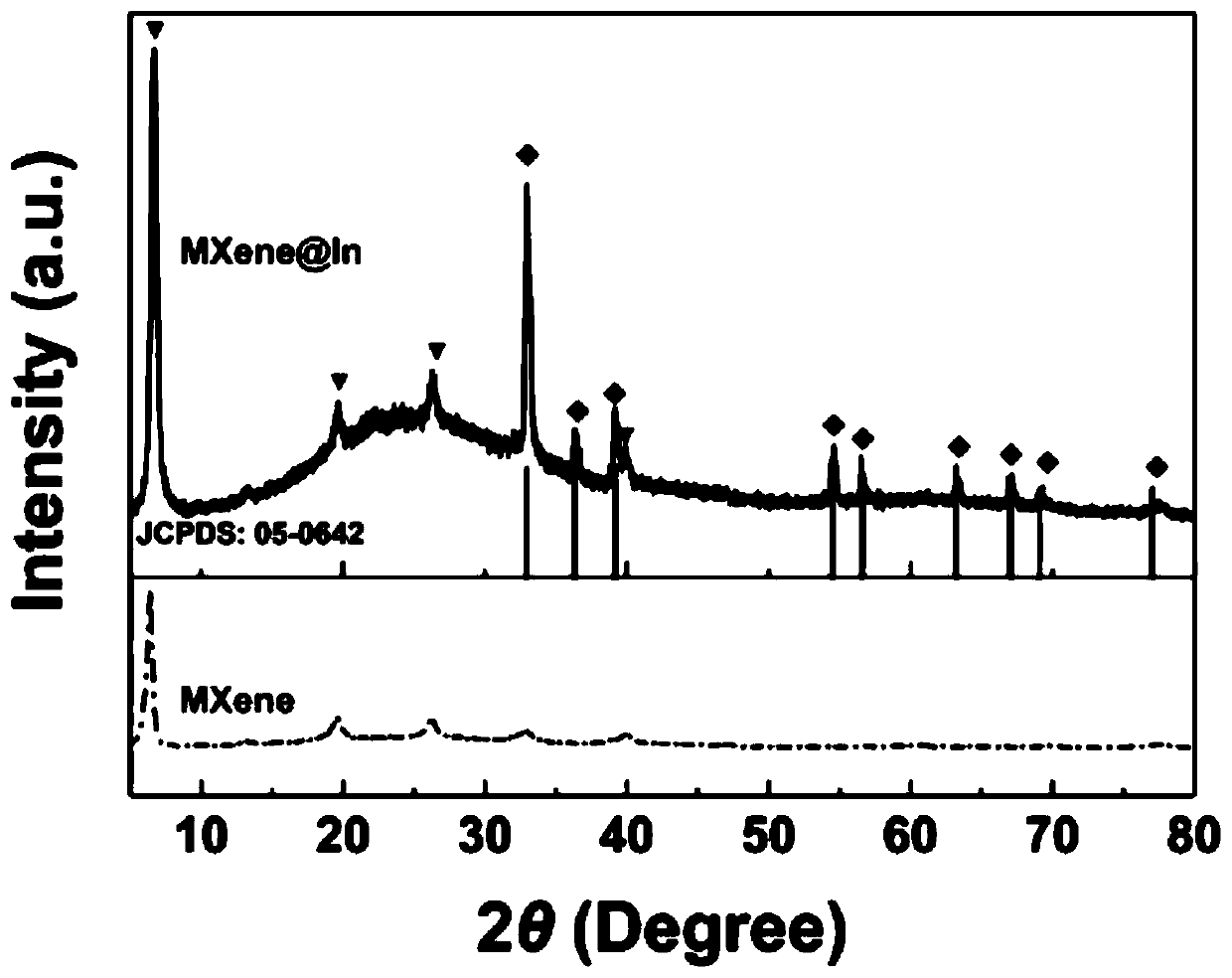

[0024] In yet another specific embodiment of the present invention, a method for preparing the above-mentioned three-dimensional layered MXene@In composite film is provided, and the preparation method includes: preparing a three-dimensional layered MXene film; electrodepositing metal indium on the three-dimensional layered MXene film.

[0025] In yet another specific embodiment of the present invention, the preparation of the three-dimensional layered MXene film includes: a homogeneous MXene colloidal solution, which is obtained by suction filtering and drying the MXene colloidal solution;

[0026] In yet another specific embodiment of the present invention, the preparation method of the homogeneous MXene colloidal solution includes: adding the powder of the MAX phase to the mixed solution of acid and fluoride, stirring, adding water, centrifuging, and forming a few layers of exfoliation by ultrasonic action Or monolayer MXene body solution;

[0027] In yet another specific em...

Embodiment 1

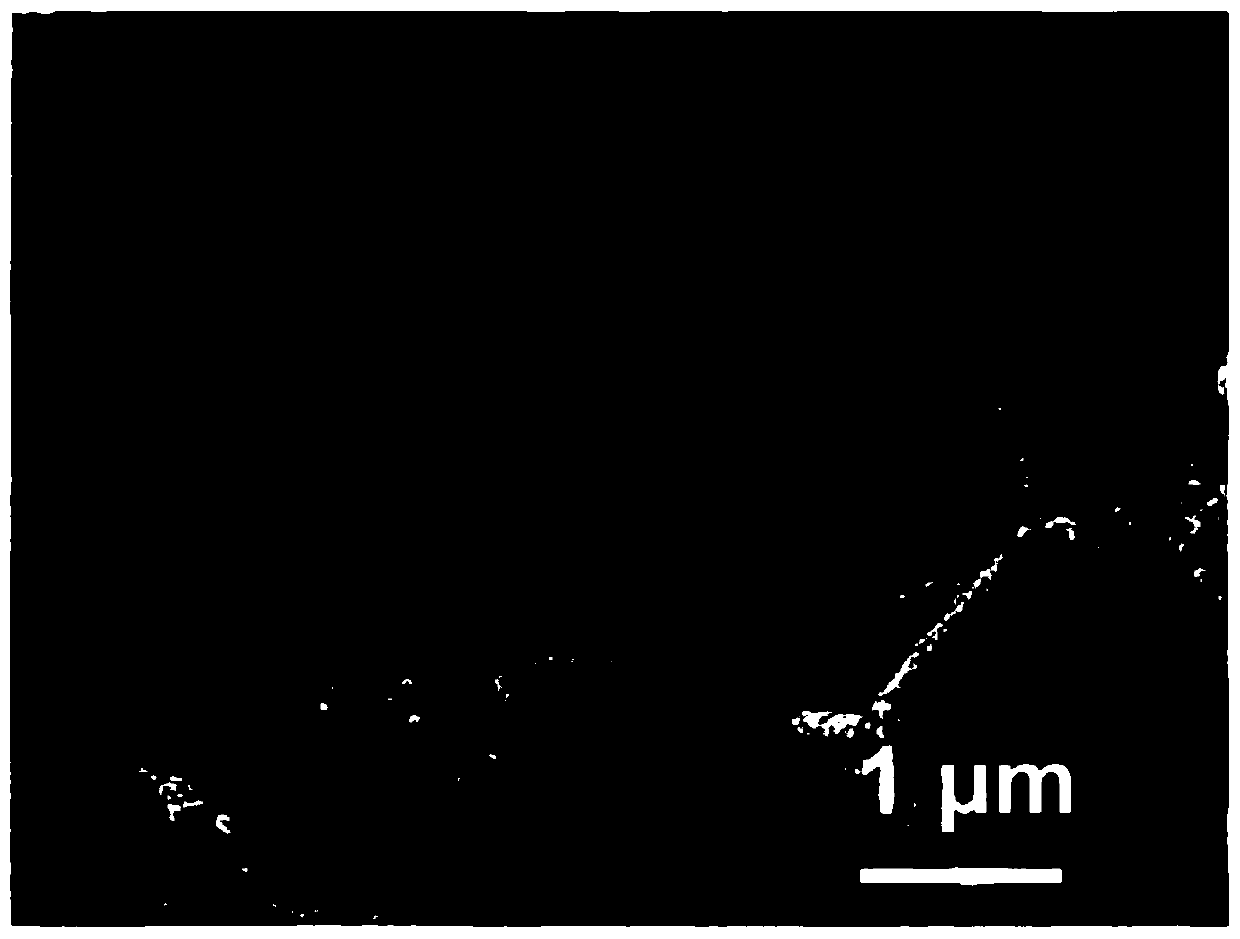

[0046] Take 0.5gTi 3 AlC 2 powder, stirred in a mixed solution of 6M hydrochloric acid 10ml and 0.5g lithium fluoride, then added water, centrifuged (3500r / min) to wash to remove excess acid and fluoride, and then ultrasonic stripped to separate the obtained few-layer MXene colloidal solution, pumped After filtration, dry in a vacuum oven at 60°C to obtain a flexible and self-supporting three-dimensional layered MXene film;

[0047] Weigh 0.0595g of indium chloride, dissolve it in 100ml of deionized water, and stir at room temperature for half an hour to obtain an electrodeposition solution;

[0048] Subsequently, in the two-electrode electrolytic cell, put the electrodeposition solution, and then use 1mA / cm 2 Constant current deposition at a current density of 1 hour, the MXene film was used as the working electrode, then washed with water, and dried at 60°C for 12 hours to obtain a flexible and self-supporting three-dimensional layered MXene@In film;

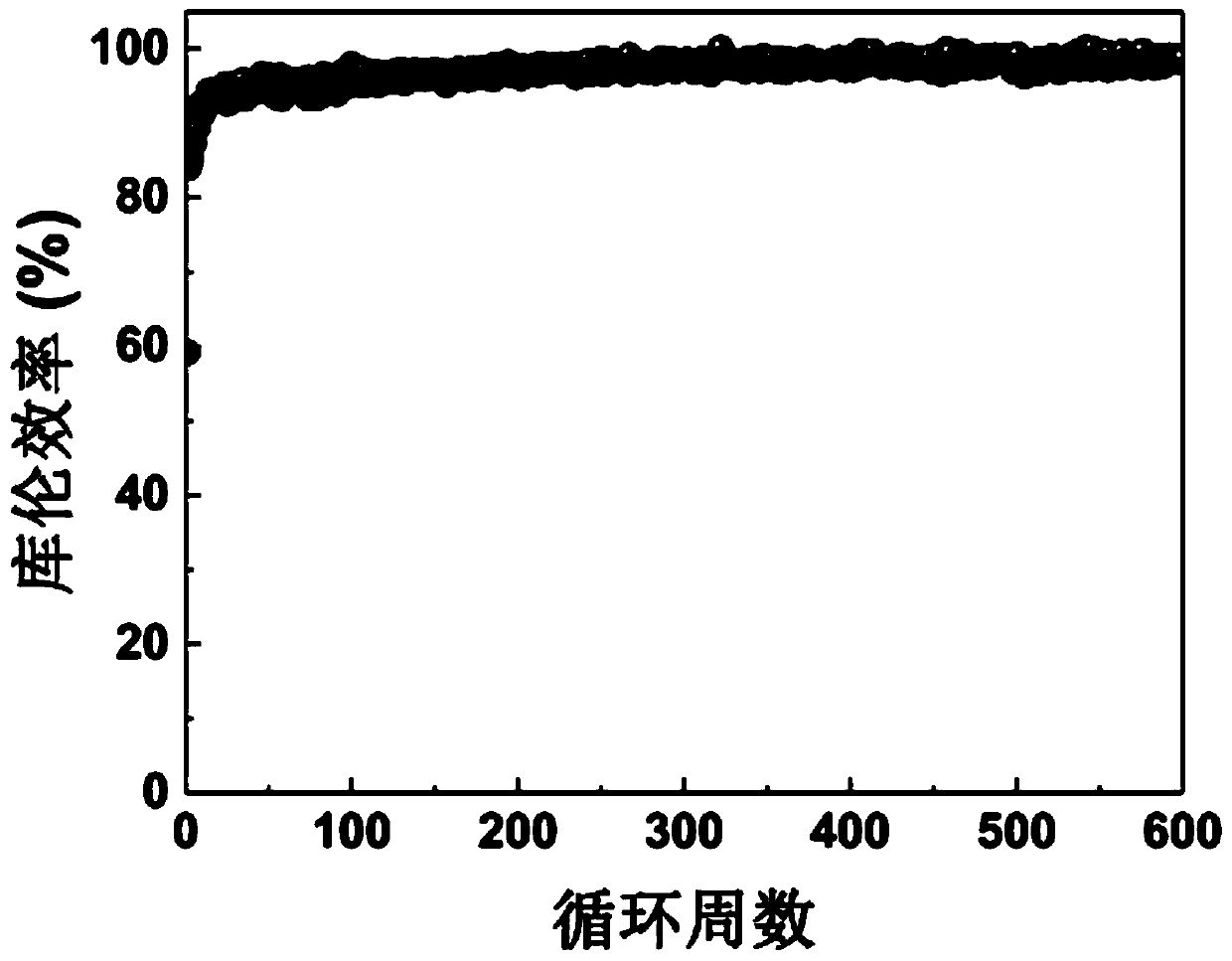

[0049] Finally, the...

Embodiment 2

[0054] Take 0.5gV 2 AlC powder, stirred in a mixed solution of 6M hydrochloric acid 10ml and 0.5g lithium fluoride, then added water, centrifuged and washed to remove excess acid and fluoride, and then ultrasonic stripped to separate the obtained few-layer MXene colloidal solution, after suction filtration, in Dry in a vacuum oven at 60°C to obtain a flexible and self-supporting three-dimensional layered MXene film;

[0055] Weigh 0.0595g of indium chloride, dissolve it in 100ml of deionized water, and stir at room temperature for half an hour to obtain an electrodeposition solution;

[0056] Subsequently, in the two-electrode electrolytic cell, put the electrodeposition solution, and then use 1mA / cm 2 Constant current deposition at a current density of 1 hour, the MXene film was used as the working electrode, then washed with water, and dried at 60°C for 12 hours to obtain a flexible and self-supporting three-dimensional layered MXene@In film;

[0057] Finally, the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com