A kind of pt-rare earth alloy material and its preparation method and application

A technology of rare earth alloys and rare earth metals, which is applied in the field of fuel cell material preparation, can solve problems such as uncertain product structure and types, unstable catalytic activity, and complicated preparation process, and achieve superior catalytic activity and stability, wide applicability, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Take platinum acetylacetonate, dysprosium acetylacetonate and didodecyltrimethylammonium bromide with a mass of 17㎎, 20㎎ and 97㎎ respectively, and add them to a two-necked flask containing 5mL oleylamine, mix and shake well, and use a power Ultrasonic treatment with 600W and frequency of 40KHz for 1 hour. Under the protection of argon, heat the oil bath to 120°C and keep it for 2 hours. Rinse 5 times in a 1:2 mixture of ethanol and hexane, and add the rinsed product to 10 mL of hexane to prepare a preposition;

[0033] 2) Weigh 60㎎ of carbon black and add it into 40mL of hexane, use a power of 600W and a frequency of 40KHz for ultrasonic treatment for 30 minutes, and add the carbon black solution after ultrasonic treatment to the preparative solution prepared in step 1). Put it in the liquid (the volume ratio of the carbon black solution to the pre-liquid is 4:1), continue to use the ultrasonic wave with a power of 600W and a frequency of 40KHz for 3 hours, wash with...

Embodiment 2

[0037] 1) Take platinum acetylacetonate, dysprosium acetylacetonate and cetyltrimethylammonium bromide with a mass of 17㎎, 17㎎ and 85㎎ respectively, and add them to a two-necked flask containing 6mL trimethylenamine, mix and shake well, Ultrasonic treatment with a power of 700W and a frequency of 50KHz for 1.5 hours. Under the protection of nitrogen, the oil bath was heated to 100°C, kept for 3 hours, and then heated to 180°C, kept for 15 hours, and naturally cooled to room temperature. Rinse 8 times in the mixed solution of ethanol and hexane with a ratio of 1:1, and add the product after washing to 8 mL of hexane to prepare the pre-flush;

[0038] 2) Weigh 50㎎ of graphene (GO) and add it to 24mL of hexane, use a power of 700W and a frequency of 50KHz for ultrasonic treatment for 20 minutes, and add the ultrasonically treated graphene solution to step 1) In the prepared pre-fluid (the volume ratio of the graphene solution to the pre-fluid is 3:1), continue to use a power of 7...

Embodiment 3

[0042] 1) Take platinum acetylacetonate, dysprosium acetylacetonate and didecyltrimethylammonium bromide with a mass of 17㎎, 22㎎ and 102㎎ respectively, and add them to a two-necked flask containing 8mL trimethylenamine, mix and shake well. Ultrasonic treatment with a power of 800W and a frequency of 60KHz for 2 hours. Under the protection of helium, heat the oil bath to 150°C and keep it for 3 hours. Then continue heating to 200°C and keep it for 12 hours. Cool naturally to room temperature. Rinse 6 times in a mixed solution of ethanol and hexane with a volume ratio of 1:3, and add the washed product to 8 mL of hexane to prepare a preposition;

[0043] 2) Weigh 45㎎ of carbon nanotubes (CT) and add them into 48mL of hexane, use a power of 800W and a frequency of 60KHz for ultrasonic treatment for 40 minutes, and add the carbon nanotube solution after ultrasonic treatment to the step 1) In the prepared pre-fluid (the volume ratio of the carbon nanotube solution and the pre-fluid...

PUM

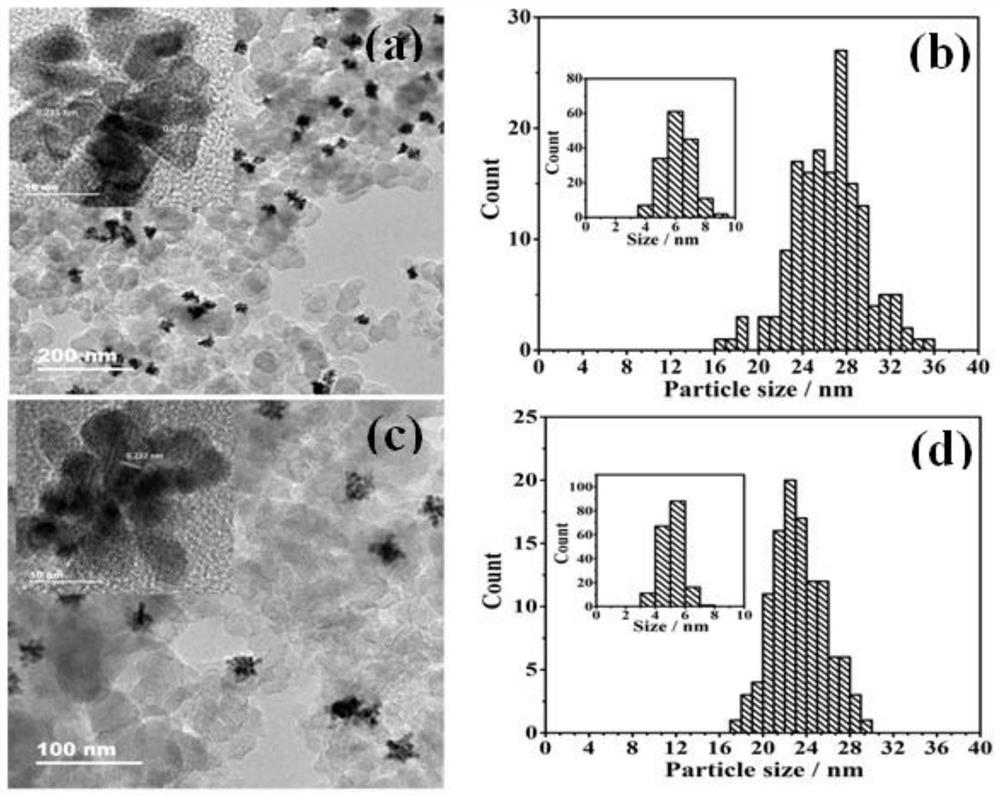

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com