Aerobic biological fluidized bed sewage treatment device and process

A sewage treatment device and aerobic biological technology, applied in the direction of biological water/sewage treatment, aerobic process treatment, sustainable biological treatment, etc., can solve the problems that the treatment effect is difficult to meet the requirements, the surface is corroded and rough, and the unfavorable carrier slips and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

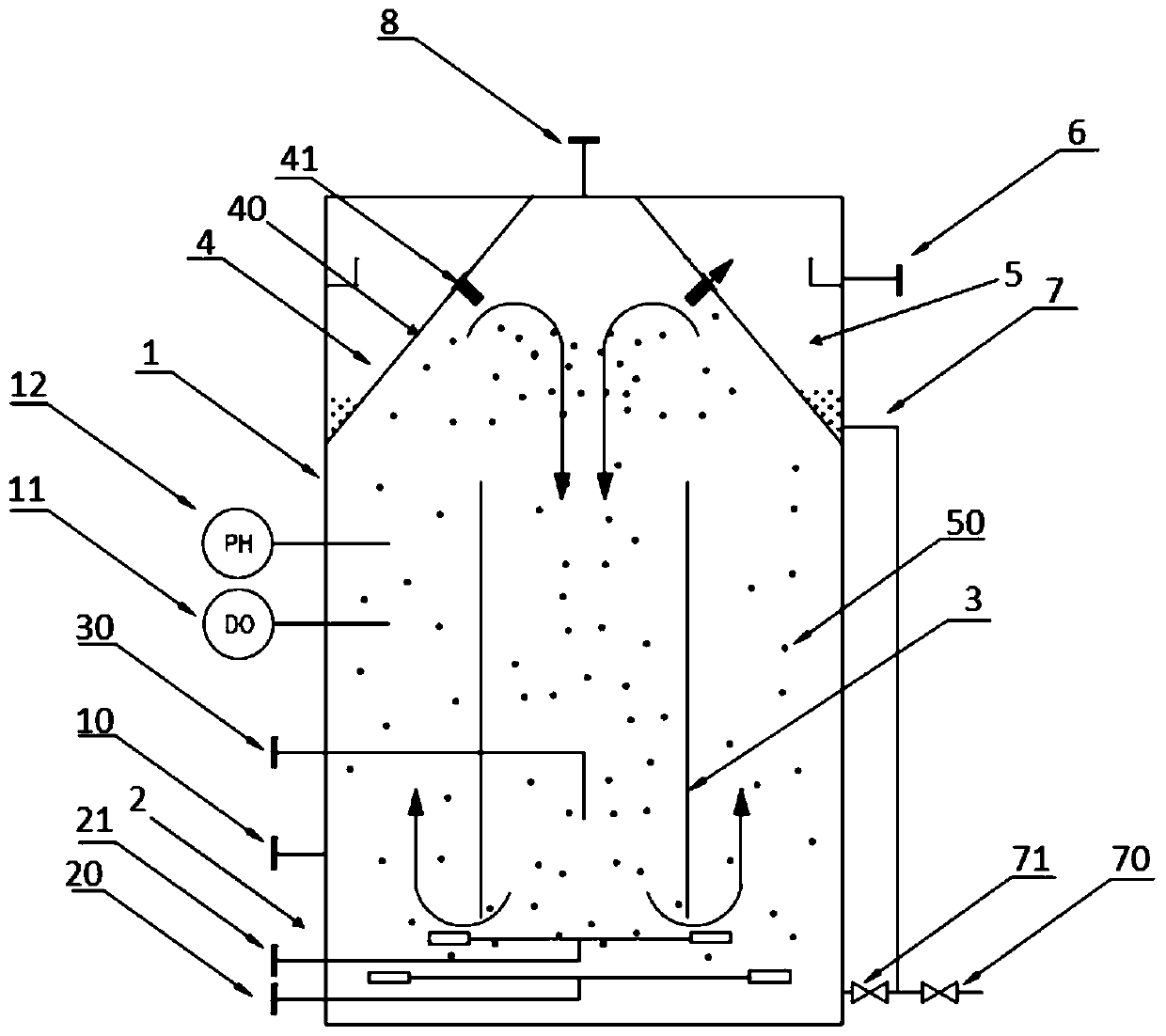

[0073] Such as figure 1 , 2 Shown, be a kind of aerobic biological fluidized bed sewage treatment process, utilize the sewage treatment device among the embodiment 1, carry out following steps:

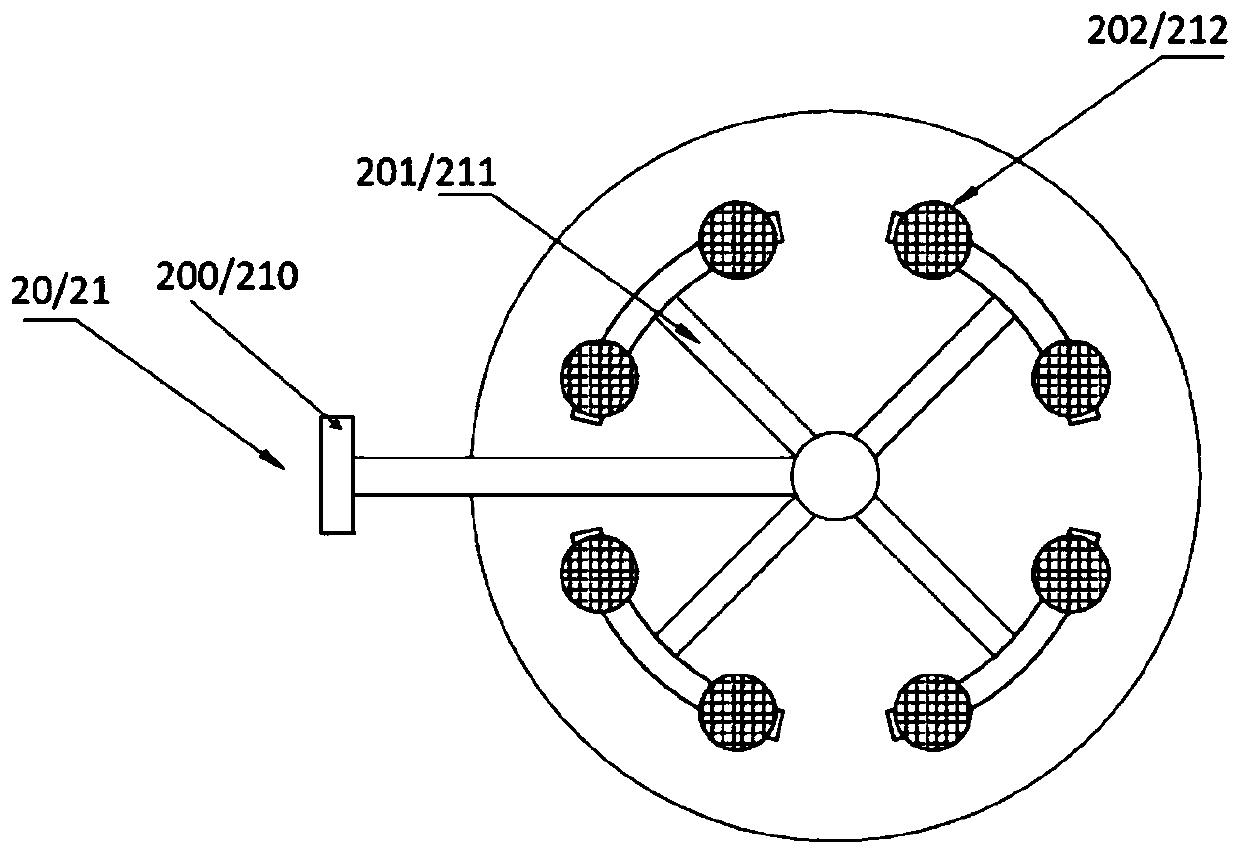

[0074] S1. The sewage sent by the water inlet pipe 30 enters the center tube 3 and the outlet faces downward, and is evenly discharged from the bottom of the center tube 3 to the surroundings under the drive of the water flow and enters between the outer wall of the center tube 3 and the inner wall of the reactor 1; it is sent by the fan The incoming air enters between the outer wall of the central cylinder 3 and the inner wall of the reactor 1 through the air aerator 20, and adjusts the air-water ratio (4-8): 1 according to the filling amount of the carrier to promote the fluidization of the carrier in the sewage;

[0075] S2. The sewage between the outer wall of the central cylinder 3 and the inner wall of the reactor 1 is aerated, the water flow density is reduced, and driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com