Waterborne epoxy heavy anti-corrosion coating and preparation method thereof

A technology for anti-corrosion coatings and water-based epoxy emulsions, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc. Coating and substrate adhesion and other issues, to achieve the effect of improving hardness and corrosion resistance, increasing glass transition temperature, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

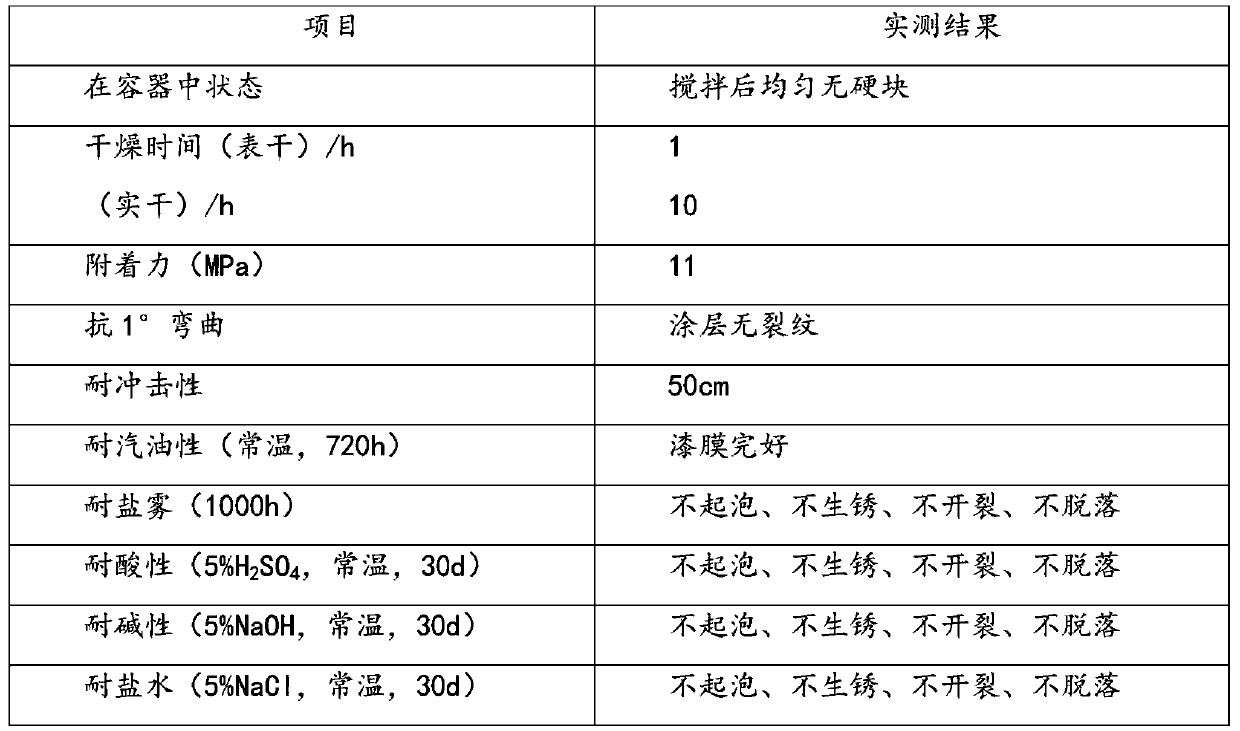

Embodiment 1

[0096] The steps of the manufacturing method of the waterborne epoxy heavy-duty anticorrosive coating of this embodiment are as follows, and the proportion of each component is parts by weight:

[0097] Step (1): Put 0.6 parts of barium sulfate, 0.5 parts of talc powder, 0.25 parts of iron red, 0.2 parts of aluminum tripolyphosphate and 0.003 parts of fumed silica in a 150℃ high temperature box to heat and remove water 12 Hours to obtain paint pigments and fillers;

[0098] Step (2): Mix 0.2 parts of deionized water, 0.02 parts of defoamer, 0.015 parts of dispersant, 0.015 parts of leveling agent, 0.05 parts of anti-flash rust agent, and 0.05 parts of bactericide and stir at room temperature. Under the circumstances, add paint pigments and fillers and 0.005 parts of modified graphene, continue to stir at high speed for 30-40 minutes to make the components uniformly dispersed, and then grind with a grinder for 0.5-1 hour to obtain a water slurry;

[0099] Step (3): Mix 1 part of the ...

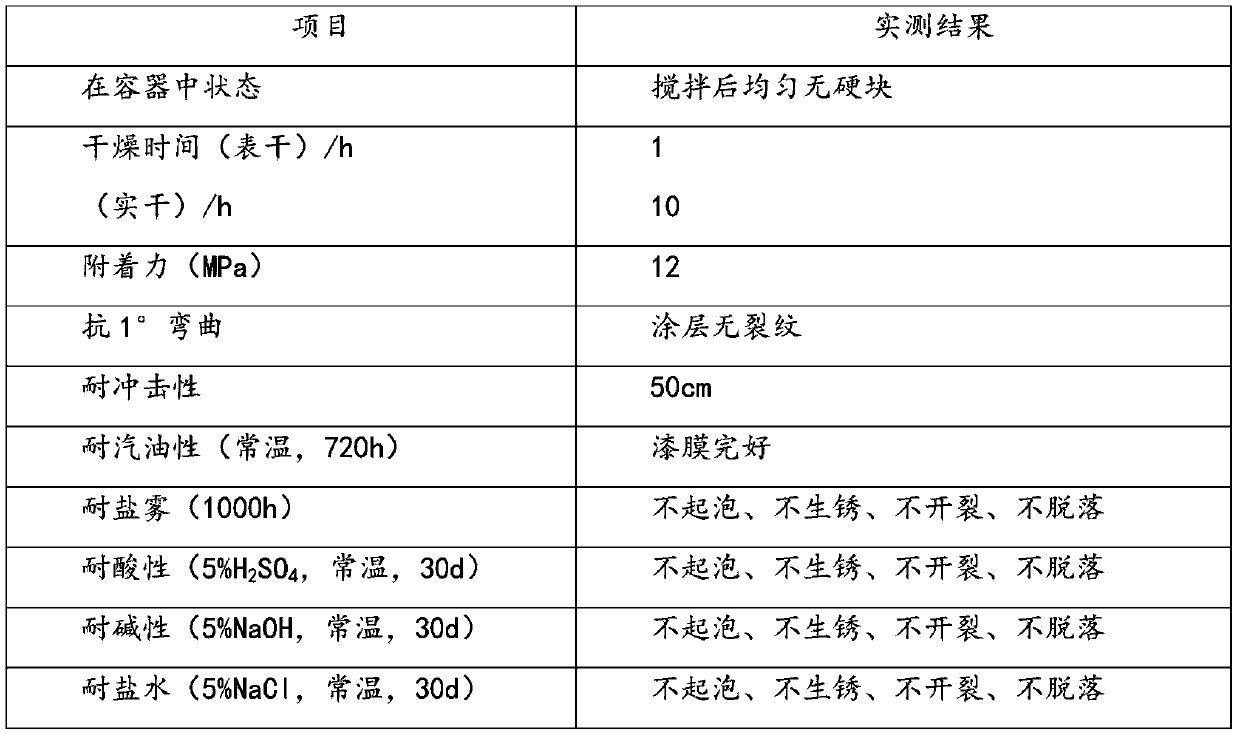

Embodiment 2

[0106] The steps of the manufacturing method of the waterborne epoxy heavy-duty anticorrosive coating of this embodiment are as follows, and the proportion of each component is parts by weight:

[0107] Step (1), place 0.6 parts of barium sulfate, 0.4 parts of talc powder, 0.3 parts of iron red, 0.2 parts of aluminum tripolyphosphate and 0.004 parts of fumed silica in a 150℃ high temperature box to heat and remove water 12 Hours to obtain paint pigments and fillers;

[0108] Step (2): Mix 0.2 parts of deionized water, 0.02 parts of defoamer, 0.015 parts of dispersant, 0.015 parts of leveling agent, 0.05 parts of anti-flash rust agent, and 0.05 parts of bactericide and stir at room temperature. Under the circumstances, add paint pigments and fillers and 0.005 parts of modified graphene, continue to stir at high speed for 30-40 minutes to make the components uniformly dispersed, and then grind with a grinder for 0.5-1 hour to obtain a water slurry;

[0109] Step (3): Mix 1 part of the...

Embodiment 3

[0116] A waterborne epoxy heavy-duty anticorrosive coating, comprising a first component and a second component, in parts by weight, the first component includes:

[0117] Modified waterborne epoxy emulsion 1 part

[0118] 0.1 part of deionized water

[0119] 0.005 parts of modified graphene

[0120] 0.45 parts of barium sulfate

[0121] 0.3 parts of talc

[0122] Iron red 0.25 parts

[0123] 0.1 part of aluminum tripolyphosphate

[0124] 0.003 parts of fumed silica.

[0125] 0.02 parts of defoamer

[0126] Dispersant 0.01 parts

[0127] 0.01 part of leveling agent

[0128] Anti-flash rust agent 0.03 parts

[0129] Fungicide 0.03 parts

[0130] 0.01 part of thickener,

[0131] The second component includes:

[0132] 1 part of water-based epoxy amine curing agent

[0133] 0.2 parts of film-forming assistant,

[0134] The weight ratio of the first component to the second component is 1:0.09,

[0135] The preparation method of the modified aqueous epoxy emulsion includes:

[0136] Mix maleic anhydride an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com