Microwave synthesis method of bismuth vanadate/bismuth phosphate compound visible-light-induced photocatalyst

A technology of microwave synthesis and bismuth phosphate, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as energy consumption and time-consuming, and achieve stable reaction system, shorten the reaction time, and improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of BiVO 4 / BiPO 4 composite photocatalyst

[0032] The preparation steps are as follows:

[0033] (1) Add 1g of sodium dodecyl sulfate (SDS) into 50mL of 1mol / L dilute nitric acid, ultrasonically disperse and dissolve, then add 4.85g of bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), ultrasonic dispersion and dissolving obtain solution A;

[0034] (2) 0.58g ammonium metavanadate (NH 4 VO 3 ), 1.79g disodium hydrogen phosphate (Na 2 HPO 4 ) was dissolved in 50mL pure water, and ultrasonically dispersed and dissolved to obtain solution B;

[0035] (3) Slowly add B to A, stir while adding, and mix well to obtain solution C;

[0036] (4) Transfer solution C into a round-bottomed flask, connect the reflux device, and microwave under the condition of microwave irradiation (the power of microwave is 650W, the intermittent work takes 30s as a working cycle, work for 12s, and stop for 18s). Heated for 20 minutes to obtain the reflux liquid;

[0037] (5) Cool the r...

Embodiment 2

[0043] 1. Product characterization

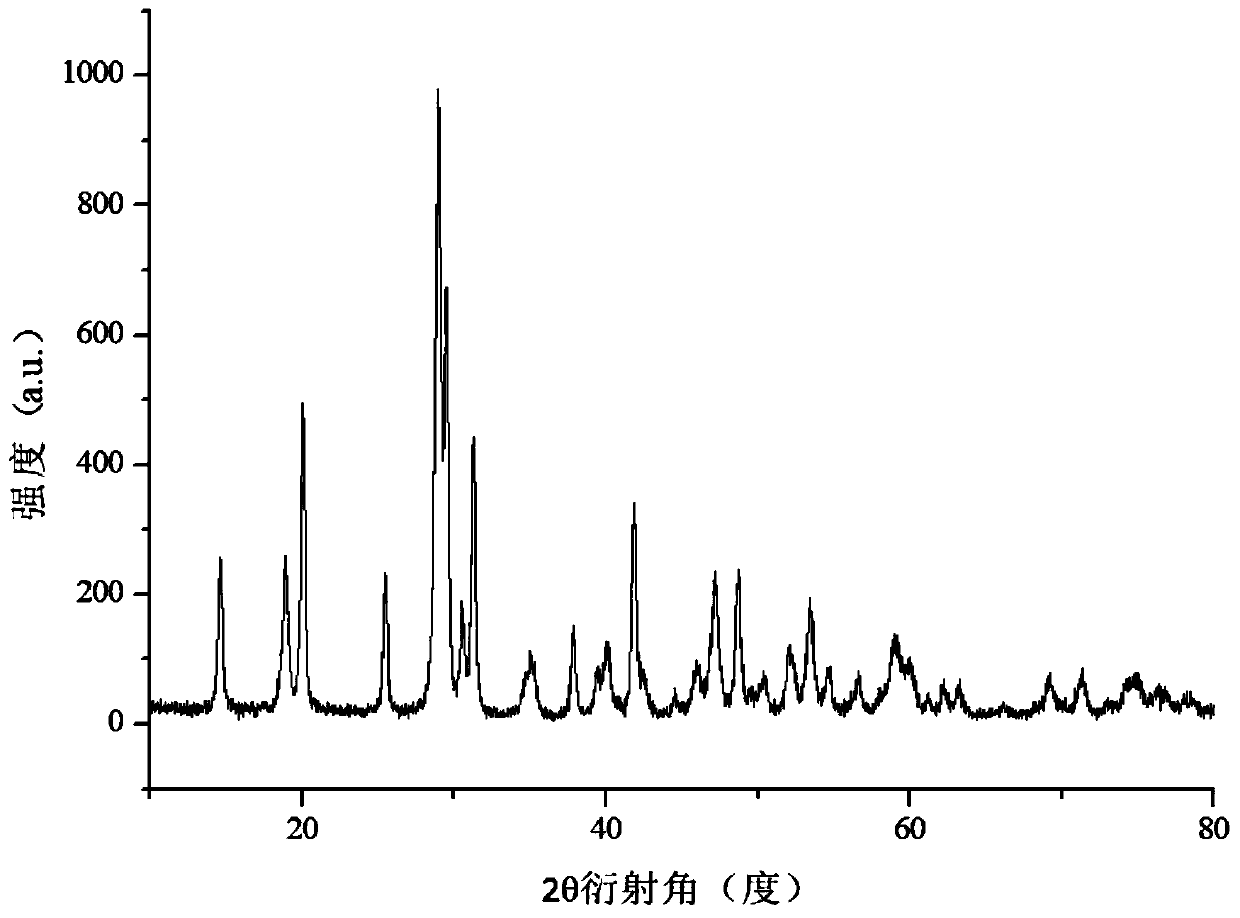

[0044] (1)XRD pattern

[0045] Such as figure 1 Shown, find that the product synthesized by embodiment 1 proves to be BiVO by comparison with the standard collection of illustrative plates 4 / BiPO 4 Complex.

[0046] (2) SEM image

[0047] from figure 2 It can be seen that the yttrium tungstate synthesized in Example 1 is a porous group structure formed by the accumulation of many small particles.

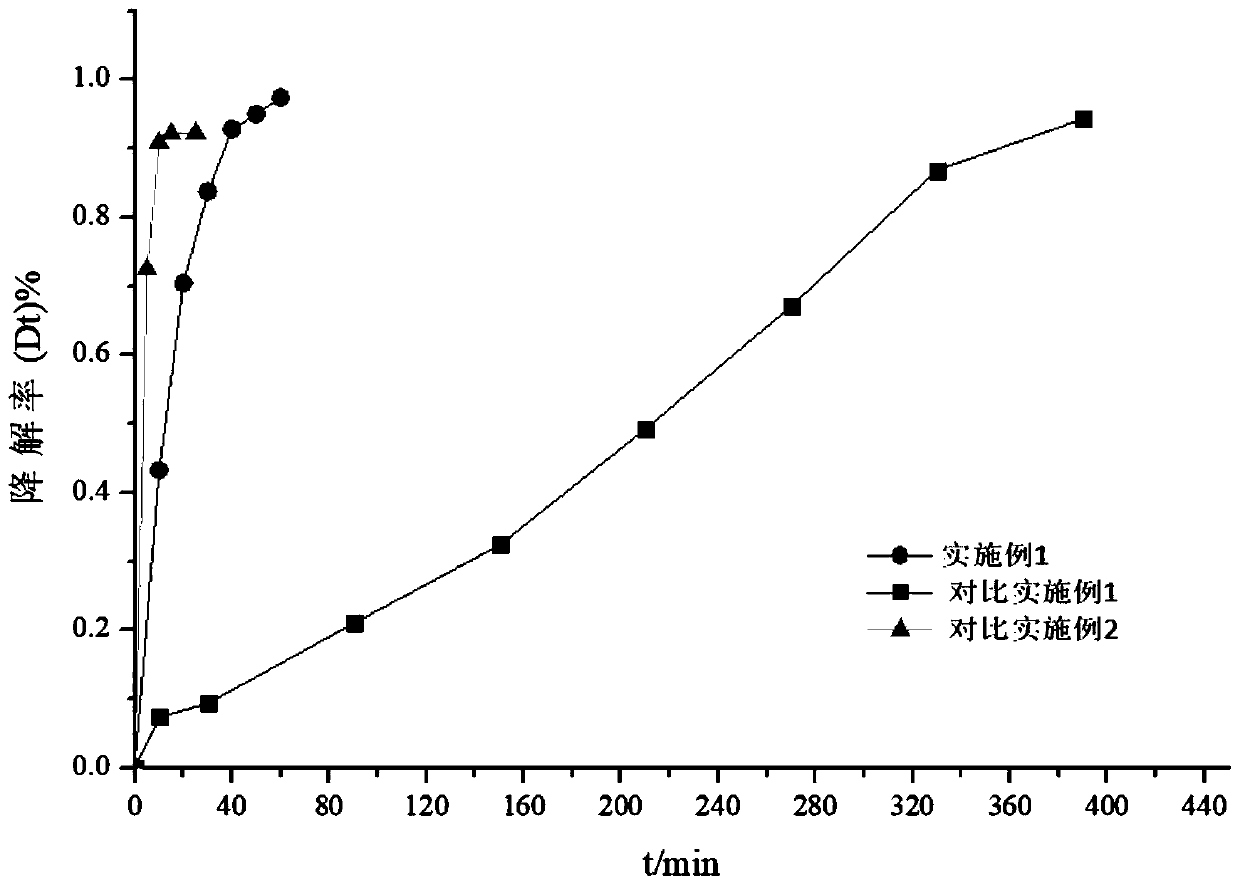

[0048] 2. Catalytic performance test

[0049] (1) Test method

[0050] Take 50mL of 10mg / L methyl orange solution in a 250ml beaker, add 1.0g / L photocatalyst, ultrasonically disperse for 30s, transfer it to a dark room, let it stand for 30min, and add 0.20ml H 2 o 2 As an initiator, a 350W xenon lamp is used as a visible light source for photocatalytic degradation of methyl orange solution (filter light below 400nm with a filter), and the height of the sample liquid level to the outlet of the xenon lamp light source is about 14cm for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com