Large-size MXene nanosheet rich in oxygen functional groups as well as preparation method and application thereof

An oxygen functional group and nanosheet technology is applied to large-sized, oxygen-rich MXene nanosheets and their preparation and application fields, which can solve the problems of small lateral size of MXene nanosheets and achieve good electrochemical performance and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

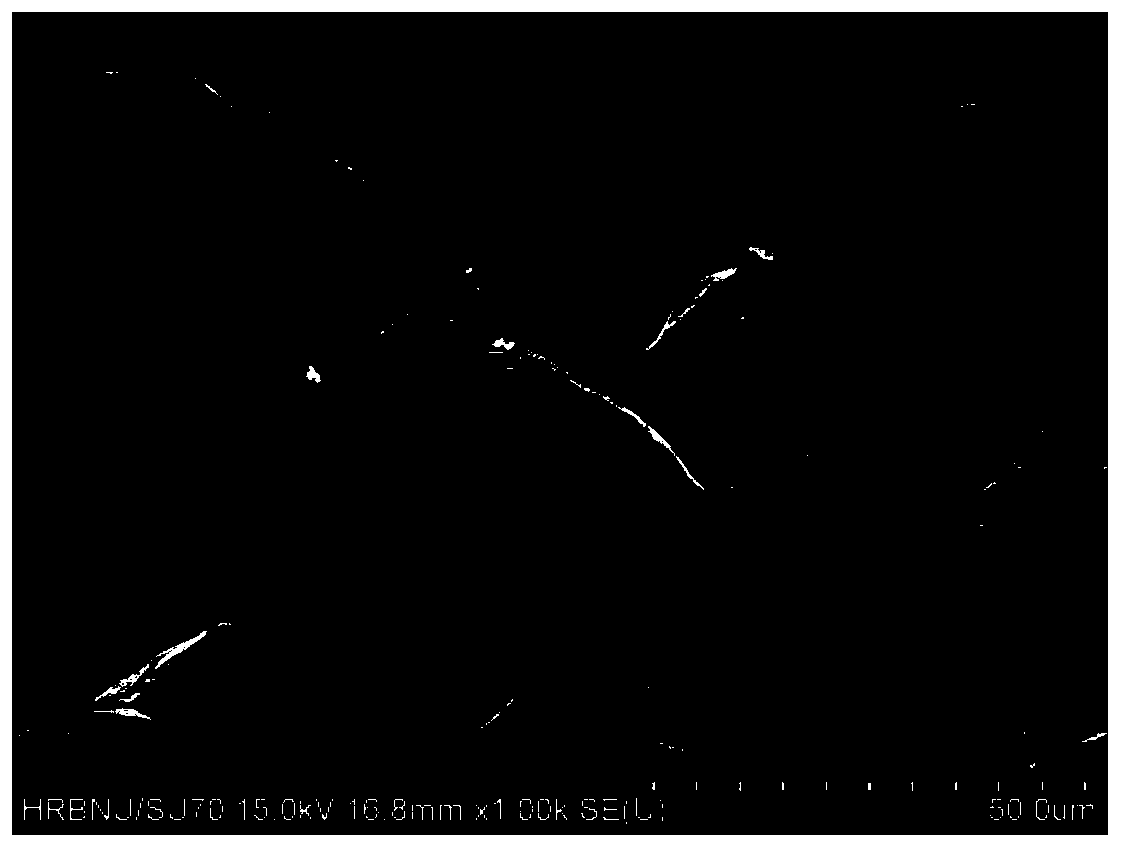

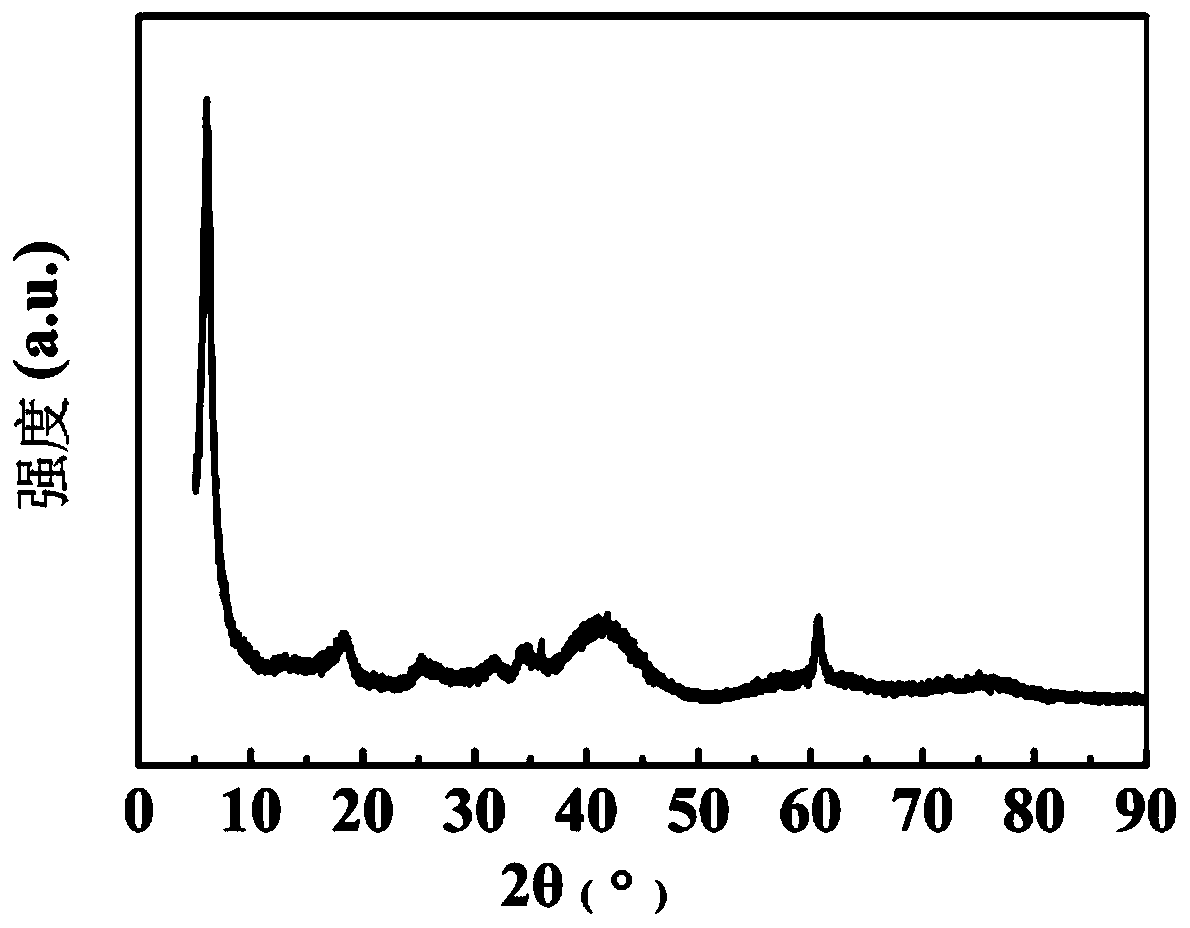

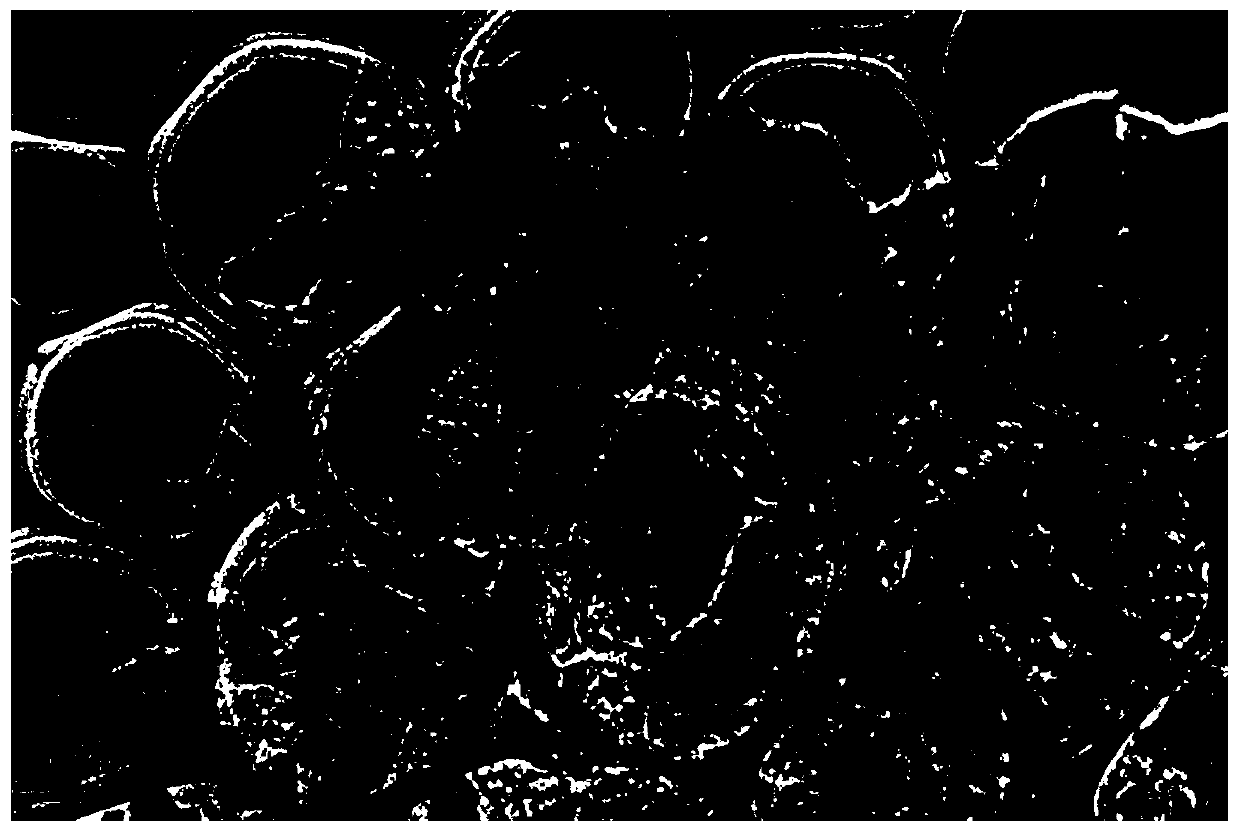

[0041] Embodiment 1: This embodiment is a large-sized, oxygen-rich MXene nanosheet stacked by multiple few-layer MXene nanosheets, with nanoscale pores between two adjacent few-layer MXene nanosheets structure, wherein the number of layers of few-layer MXene nanosheets is 1-5 layers, and the thickness is 1nm-6nm; the lateral dimension of the large-sized, oxygen-rich MXene nanosheets is more than 50 μm, and the thickness is 10nm-30nm .

specific Embodiment approach 2

[0042] Specific embodiment two: the present embodiment is a kind of preparation method of the MXene nanosheet of large size, rich in oxygen functional group is finished according to the following steps:

[0043] 1. Centrifuge the two-dimensional MXene nanosheet suspension, pour off the supernatant, and obtain a muddy precipitate;

[0044] 2. First, add deionization to the muddy sediment, stir evenly to obtain a viscous MXene nanosheet slurry; then put the viscous MXene nanosheet slurry in a minus 80-degree ultra-low temperature refrigerator for 2h to 3h, and finally put Freeze drying in a freeze dryer to obtain a freeze-dried product;

[0045] 3. Place the lyophilized product in a solvent for ultrasonication to obtain large-sized, oxygen-rich MXene nanosheets dispersed in the solvent;

[0046] The volume ratio of the mass of the freeze-dried product described in step 3 to the solvent is (1mg-5mg): (1mL-10mL).

[0047] This embodiment has the following beneficial effects:

...

specific Embodiment approach 3

[0058] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the preparation method of the two-dimensional MXene nanosheet suspension described in step one is completed in the following steps:

[0059] ①. Add lithium fluoride to hydrochloric acid with a concentration of 6mol / L-12mol / L, and then magnetically stir at a stirring speed of 300r / min-500r / min for 5min-10min to obtain a lithium fluoride hydrochloric acid solution;

[0060] The mass of lithium fluoride described in step 1. and the concentration are that the volume ratio of the hydrochloric acid of 6mol / L~12mol / L is (1g~3g):20mL;

[0061] ②. Add the ternary layered compound MAX powder to the lithium fluoride hydrochloric acid solution in 3 to 15 times under the condition of an ice-water bath and a stirring speed of 200r / min to 1000r / min, and stir until the ternary layered compound MAX powder Uniformly disperse in the lithium fluoride hydrochloric acid solution, then magnetical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com