Preparation method of nanocrystalline porous titanium dioxide film on flexible substrate

A technology of porous titanium dioxide and flexible substrates, applied in the direction of coating, etc., can solve the problems of incomplete crystal transformation of titanium dioxide, low photoelectric activity, etc., and achieve the effect of simple operation, low price and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

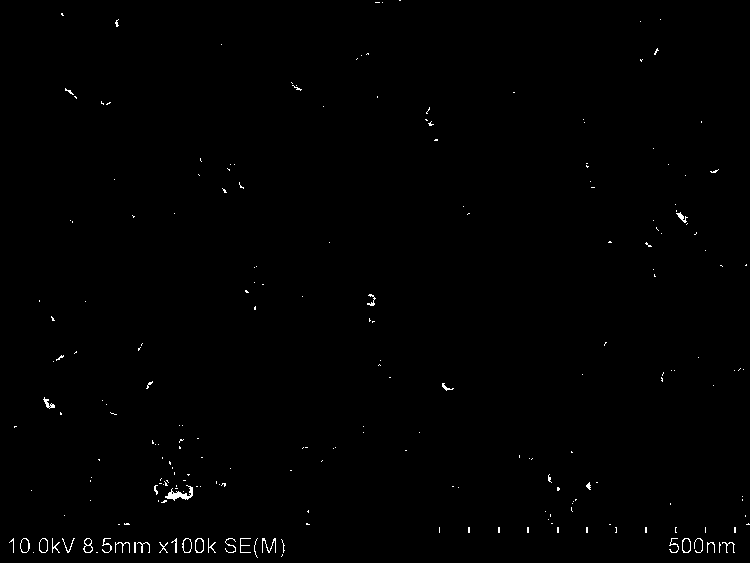

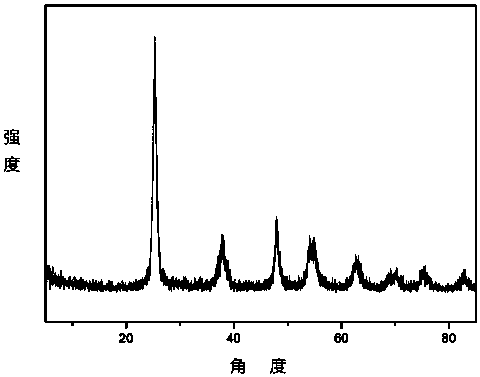

Image

Examples

Embodiment 1

[0014] A nanocrystalline porous titanium dioxide film on a flexible substrate is prepared by a hydrothermal / screen printing composite method, and the steps are as follows:

[0015] (1) Preparation of titanium dioxide colloid: Take 20ml of butyl titanate and glacial acetic acid, mix them evenly in a beaker, and let it stand; add 120ml of distilled water to the beaker, add about 6ml of diethanolamine under vigorous stirring, and continue stirring for 4h , until a milky white translucent hydrothermal precursor solution is obtained; the precursor solution is added to a hydrothermal autoclave, and the hydrothermal reaction is performed at 150 °C for 24 hours to generate nano-TiO 2 Colloidal solution;

[0016] (2) Preparation of colloids for screen printing: Nano-TiO produced by hydrothermal 2 The colloidal solution was taken out, after ultrasonic dispersion, an industrial viscous agent with a mass fraction of 10% was added, heated at a constant temperature of 80°C, stirred to an a...

Embodiment 2

[0018] A nanocrystalline porous titanium dioxide film on a flexible substrate, prepared according to the following steps:

[0019] (1) Preparation of titanium dioxide colloid: Take 20ml of butyl titanate and glacial acetic acid, mix them evenly in a beaker, and let it stand; add 120ml of distilled water to the beaker, add about 6ml of diethanolamine under vigorous stirring, and continue stirring for 4h , until a milky white translucent hydrothermal precursor solution is obtained; the precursor solution is added to a hydrothermal autoclave, and the hydrothermal reaction is performed at 150°C for 24 hours to generate nano-TiO 2 Colloidal solution;

[0020] (2) Preparation of colloids for screen printing: Nano-TiO produced by hydrothermal 2 The colloidal solution was taken out, after ultrasonic dispersion, carboxymethyl cellulose with a mass fraction of 30% was added as an industrial viscous agent, heated at a constant temperature of 80°C, stirred to an appropriate viscosity, an...

Embodiment 3

[0022] A nanocrystalline porous titanium dioxide film on a flexible substrate, prepared according to the following steps:

[0023] (1) Preparation of titanium dioxide colloid: Take 20ml of butyl titanate and glacial acetic acid, mix them evenly in a beaker, and let it stand; add 120ml of distilled water to the beaker, add about 6ml of diethanolamine under vigorous stirring, and continue stirring for 4h , until a milky white translucent hydrothermal precursor solution is obtained; the precursor solution is added to a hydrothermal autoclave, and the hydrothermal reaction is performed at 150°C for 24 hours to generate nano-TiO 2 Colloidal solution;

[0024] (2) Preparation of colloids for screen printing: Nano-TiO produced by hydrothermal 2 The colloidal solution was taken out, and after ultrasonic dispersion, 10% carboxymethyl cellulose and 15% carboxyethyl cellulose were added as industrial viscous agents, heated at a constant temperature of 80°C, and stirred to an appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com