Purification treatment method and purification treatment device for garbage incineration flue gas

A purification treatment and waste incineration technology, which is applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve the problem of increasing the volume of SCR reactor, investment and catalyst consumption, affecting the total power generation and overall economic benefits of waste incineration plants, Problems such as high investment in heat exchangers and steam heaters, to achieve the effect of improving SCR denitrification efficiency, avoiding scale increase, and saving steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

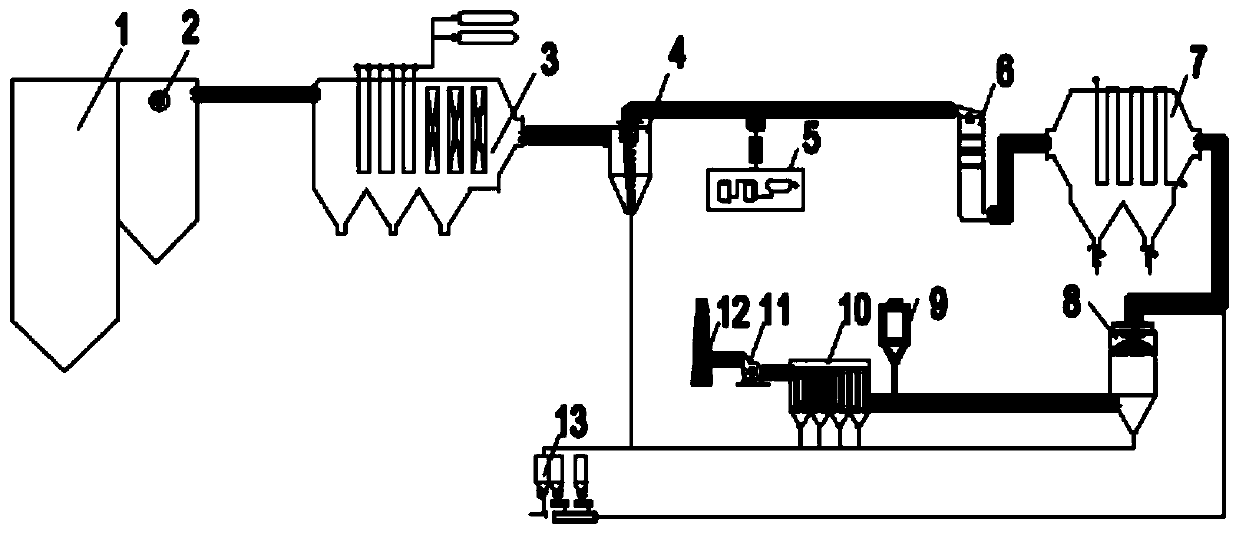

[0063]This embodiment provides a purification treatment device for waste incineration flue gas, including: an evaporator, a cyclone dust collector, an SCR system, an economizer, a semi-dry deacidification system, an activated carbon injection system, and a bag-type dust removal system connected in sequence.

[0064] Wherein, the SCR system includes: an SCR reactor; a denitrification reducing agent storage injection system, which is connected to the SCR reactor pipeline for supplying and injecting reducing agent; a soot cleaning and blowing system, which is connected to the SCR reactor pipeline connection, for cleaning the dust in the SCR reactor; and the SCR catalyst.

[0065] The denitration reductant storage and injection system includes: a reductant storage system and a reductant injection system; the reductant can be liquid ammonia, urea or ammonia water.

[0066] Wherein, when liquid ammonia is used as the reducing agent, the denitrification reducing agent storage and inj...

Embodiment 2

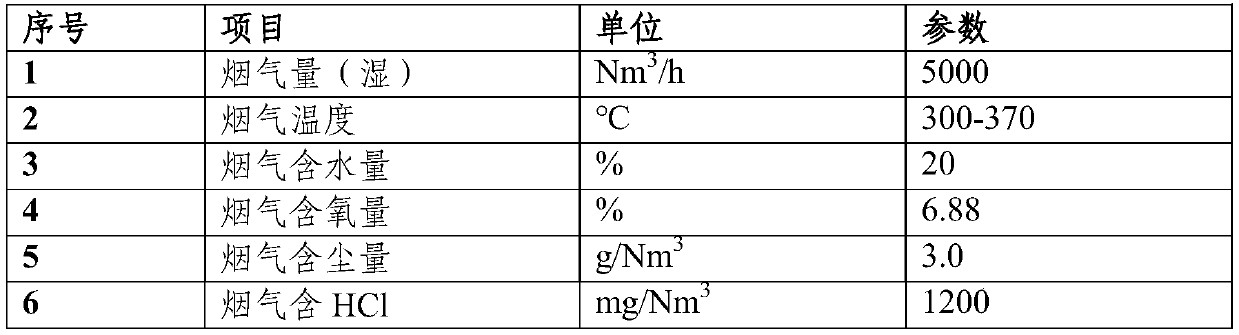

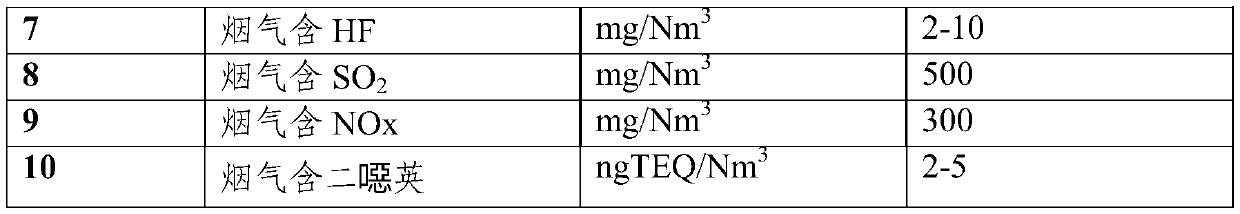

[0074] Taking a 400t / d waste incineration plant as an example, its flue gas composition is shown in Table 1.

[0075] Table 1

[0076]

[0077]

[0078] Adopt purification treatment device described in the present invention to carry out purification treatment, concrete steps are as follows:

[0079] (1) The flue gas is drawn from the evaporator at a flow rate of 13m / s, and the dust is removed by the cyclone dust collector, and the dust removal efficiency is 50%;

[0080] (2) The flue gas after dedusting enters the SCR system and is mixed with the reducing agent to carry out the SCR denitrification reaction;

[0081] Wherein, the reaction temperature of the SCR denitrification is 350°C;

[0082] The catalyst used for the SCR denitrification is the 18-hole garbage incineration flue gas denitrification special catalyst produced by CECEP Liuhe Tianrong (Shandong) Catalyst Company;

[0083] NH in the SCR denitrification process 3 with NO x The molar ratio is 1.2:1;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com