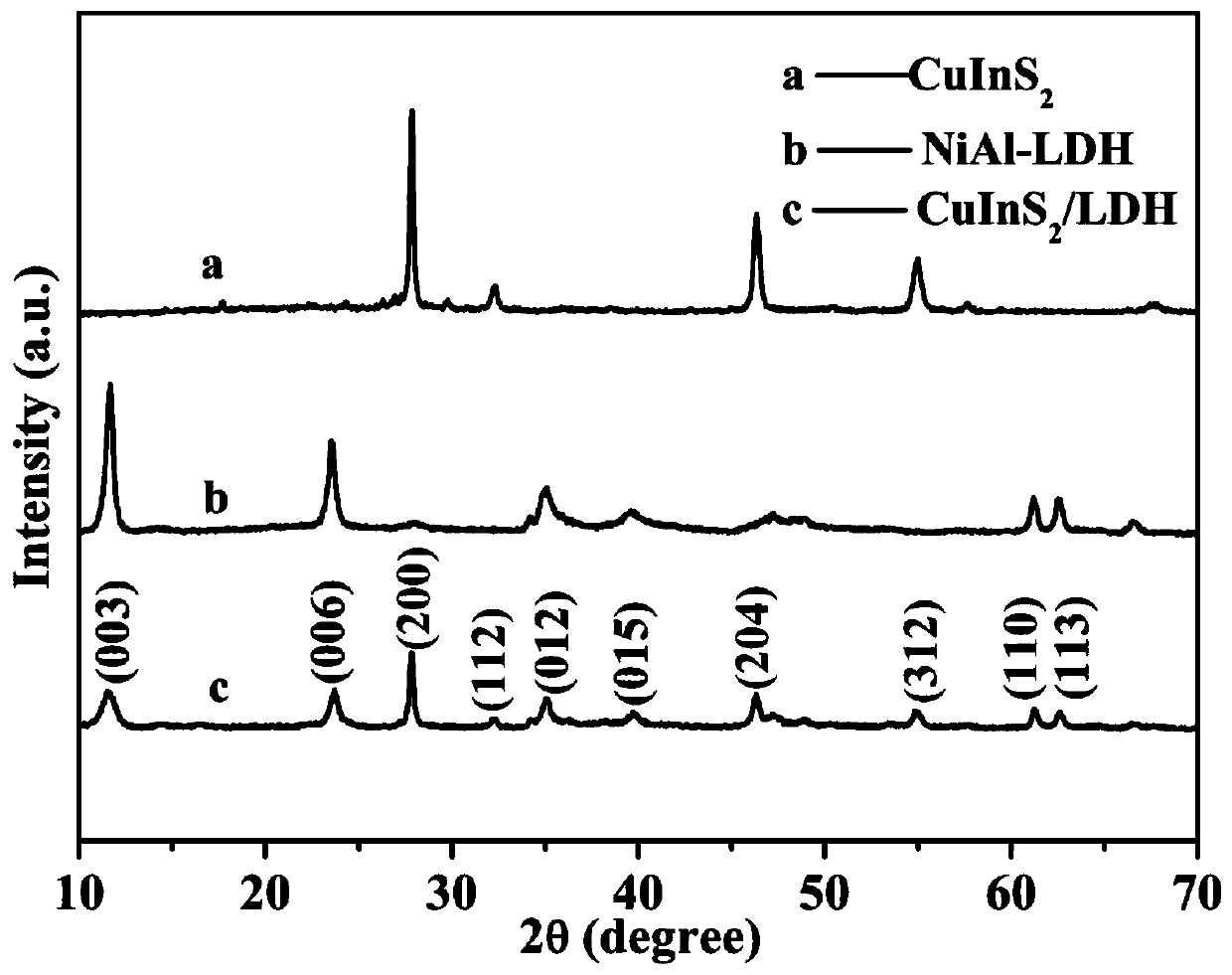

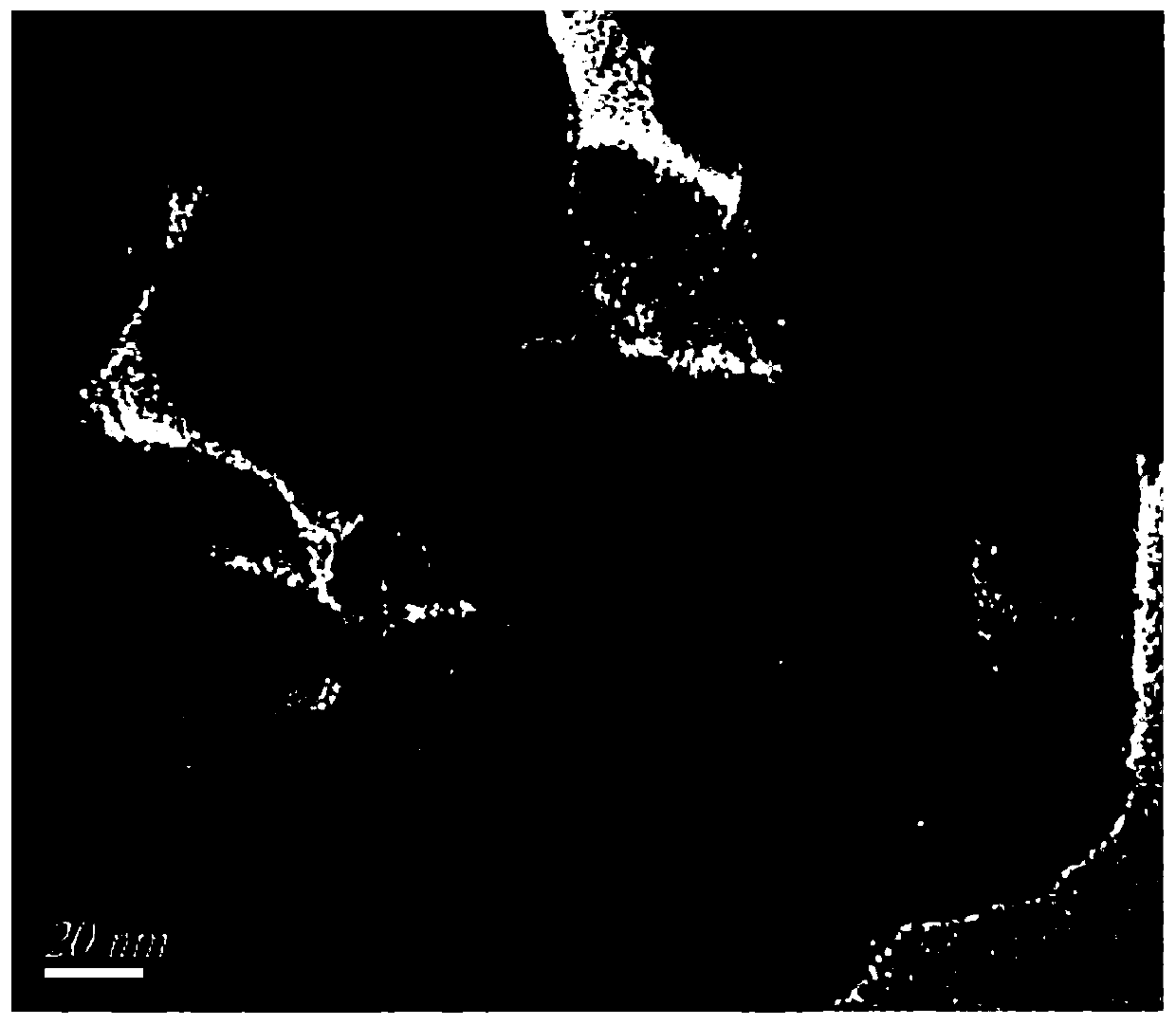

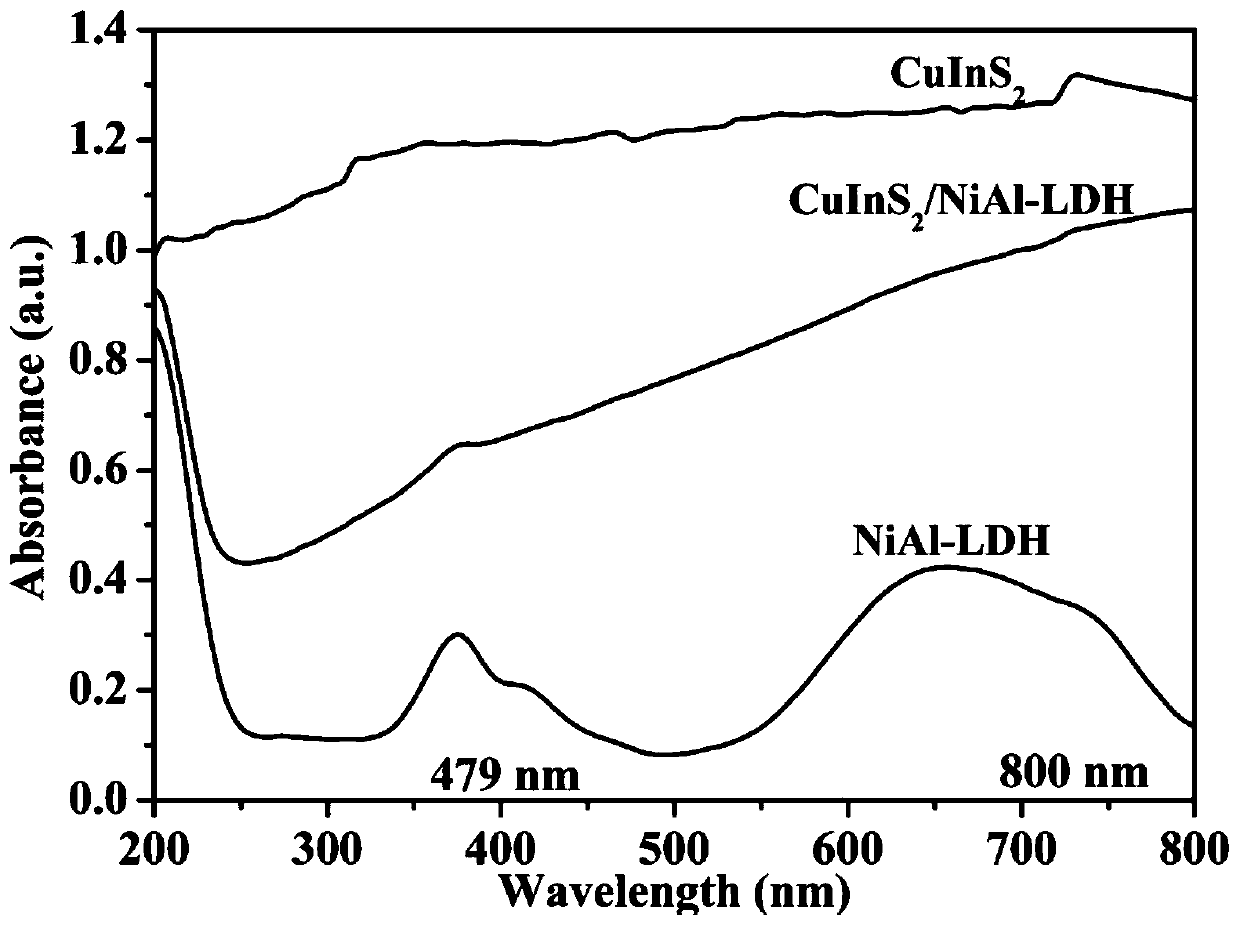

Preparation method and application of CuInS2 quantum dot/NiAl-LDH composite photocatalyst

A photocatalyst, quantum dot technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of good separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) CuInS 2 Preparation of Quantum Dot Photocatalyst

[0033] Put 0.17g of copper chloride dihydrate and 20mL of ethylenediamine into a small beaker, dissolve them all, add 0.22g of indium chloride and 0.24g of L-cysteine, add 20ml of deionized water and magnetically stir to assist the reaction 30min; Pour into a high-pressure reaction kettle and heat at 150°C for 7h in a blast drying oven, take it out and let it cool naturally, centrifuge, wash with deionized water and ethanol three times each, put it in a blast drying oven to dry, and obtain CuInS 2 Quantum dot photocatalyst.

[0034] (2) Preparation of NiAl-LDH photocatalyst

[0035] Weigh 1.875g of nickel nitrate hexahydrate and 2.181g of aluminum nitrate into a small beaker, add deionized water until completely dissolved, add 2.453g of urotropine, magnetically stir the reaction for 1h, and pour it into a high-pressure reactor with a drum Heat in an air drying oven at 150°C for 7 hours, take it out and let it coo...

Embodiment 2

[0040] (1) CuInS 2 Preparation of Quantum Dot Photocatalyst

[0041] Put 0.17g of copper chloride dihydrate and 20mL of ethylenediamine into a small beaker to dissolve them all, then add 0.22g of indium chloride and 0.24g of L-cysteine, add 20ml of deionized water and stir magnetically Auxiliary reaction for 30 minutes, poured into a high-pressure reaction kettle and heated at 160°C for 5 hours in a blast drying oven, took it out and cooled it naturally, centrifuged the solution, washed with deionized water and ethanol three times, put it in a blast drying oven to dry, and obtained CuInS 2 Quantum dot photocatalyst.

[0042] (2) Preparation of NiAl-LDH photocatalyst

[0043] Weigh 1.875g of nickel nitrate hexahydrate and 2.181g of aluminum nitrate into a small beaker, add deionized water until completely dissolved, add 2.453g of urotropine, magnetically stir the reaction for 1h, and pour it into a high-pressure reactor with a drum Heated in an air drying oven at 160°C for 5...

Embodiment 3

[0050] (1) CuInS 2 Preparation of Quantum Dot Photocatalyst

[0051] Put 0.17g of copper chloride dihydrate and 20mL of ethylenediamine into a small beaker, dissolve them all, add 0.22g of indium chloride and 0.24g of L-cysteine, measure 20ml of deionized water with the aid of magnetic stirring React for 50 minutes. Pour it into a high-pressure reaction kettle and heat it in a blast drying oven at 180°C for 4 hours, take it out and cool it naturally, centrifuge the solution, wash it with deionized water and ethanol three times each, and dry it in a blast drying oven to obtain CuInS 2 Quantum dot photocatalyst.

[0052] (2) Preparation of NiAl-LDH photocatalyst

[0053] Weigh 1.875g of nickel nitrate hexahydrate and 2.181g of aluminum nitrate into a small beaker, add deionized water until completely dissolved, add 2.453g of urotropine, magnetically stir the reaction for 1h, and pour it into a high-pressure reactor with a drum Heat in an air drying oven at 180°C for 4 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com