Method for degrading PPCPs by metal ion doped MoS2 activated monopersulfate

A metal ion and persulfate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems that have not been seen before, achieve simple operation, improve electrical conductivity and catalytic activity, and excellent The effect of anti-leaching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

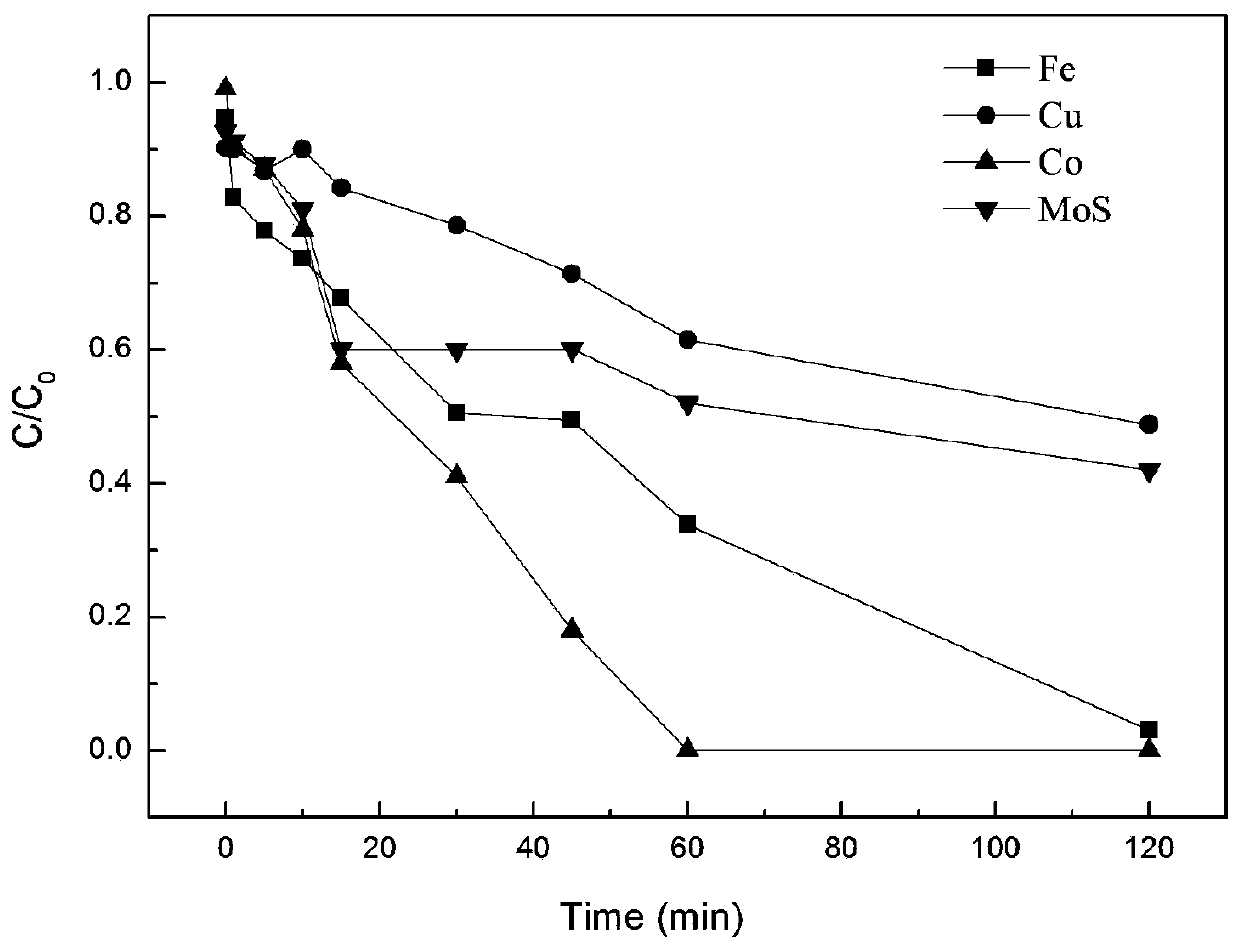

[0053] like figure 1 , MoS is doped with copper ions, iron ions and cobalt ions in this example 2 Activated method for the degradation of PPCPs by monopersulfate using MoS doped with metal ions 2 To activate monopersulfate, the specific preparation steps are as follows:

[0054] Step 1. Preparation of metal ion-doped MoS 2 ,Specific steps are as follows:

[0055] 1.1 Add ammonium molybdate and thiourea into water according to the molar ratio of 1:2, and ultrasonicate for 1-2h to obtain a uniformly mixed reaction solution;

[0056] 1.2 Transfer the reaction solution into a polytetrafluoroethylene autoclave and react at 160-200°C for 24 hours; after the reaction kettle is cooled to room temperature, the reaction solution is removed and centrifuged, washed with deionized water and centrifuged several times; the product Move to 40-60℃ oven to dry for 12-18h; get MoS with mixed valence state 2 ;

[0057] 1.3 Mix 30 mL of water and 40 mg of the above synthesized valence MoS 2...

Embodiment 2

[0070] Step 1. Preparation of metal ion-doped MoS 2 ,Specific steps are as follows:

[0071] 1.1 Add molybdenum oxide and thioacetamide into water according to the molar ratio of 1:2.5, and ultrasonicate for 1.5h to obtain a uniformly mixed reaction solution;

[0072] 1.2 The reaction solution was transferred into a polytetrafluoroethylene autoclave and reacted at 180°C for 24 hours; after the reaction kettle was cooled to room temperature, the reaction solution was removed and centrifuged, washed with deionized water and centrifuged several times; the product was moved to Dry in an oven at 50°C for 12-18h; obtain MoS with mixed valence states 2 ;

[0073] 1.3 Mix 30 mL of water and 40 mg of the above synthesized valence MoS 2 Put it into a three-necked flask, ultrasonicate it for 1-2 hours, and mix it thoroughly to obtain a mixed solution;

[0074] 1.4 Prepare 50 mL of an aqueous solution of 0.001 mol of metal ions, mix the aqueous solution containing metal ions with the ...

Embodiment 3

[0087] This embodiment is basically the same as Embodiment 1, and the main difference is:

[0088] In step 1, MoS 2 / Co or MoS 2 The amount of Fe is different, MoS was investigated in this example 2 / Co or MoS 2 When the dosage of Fe / Fe is 0.02g / L, 0.04g / L, 0.06g / L, 0.08g / L and 0.1g / L, for the pollutant solution containing diclofenac sodium (the initial concentration of diclofenac sodium is 10mg / L) Treatment effect; the stirring speed of mixing the two is 400 rpm, the temperature is 25° C., and the pH of the mixed solution obtained in step 1 is adjusted to 6.5 by using 0.1 mM HCl and 0.1 mM NaOH.

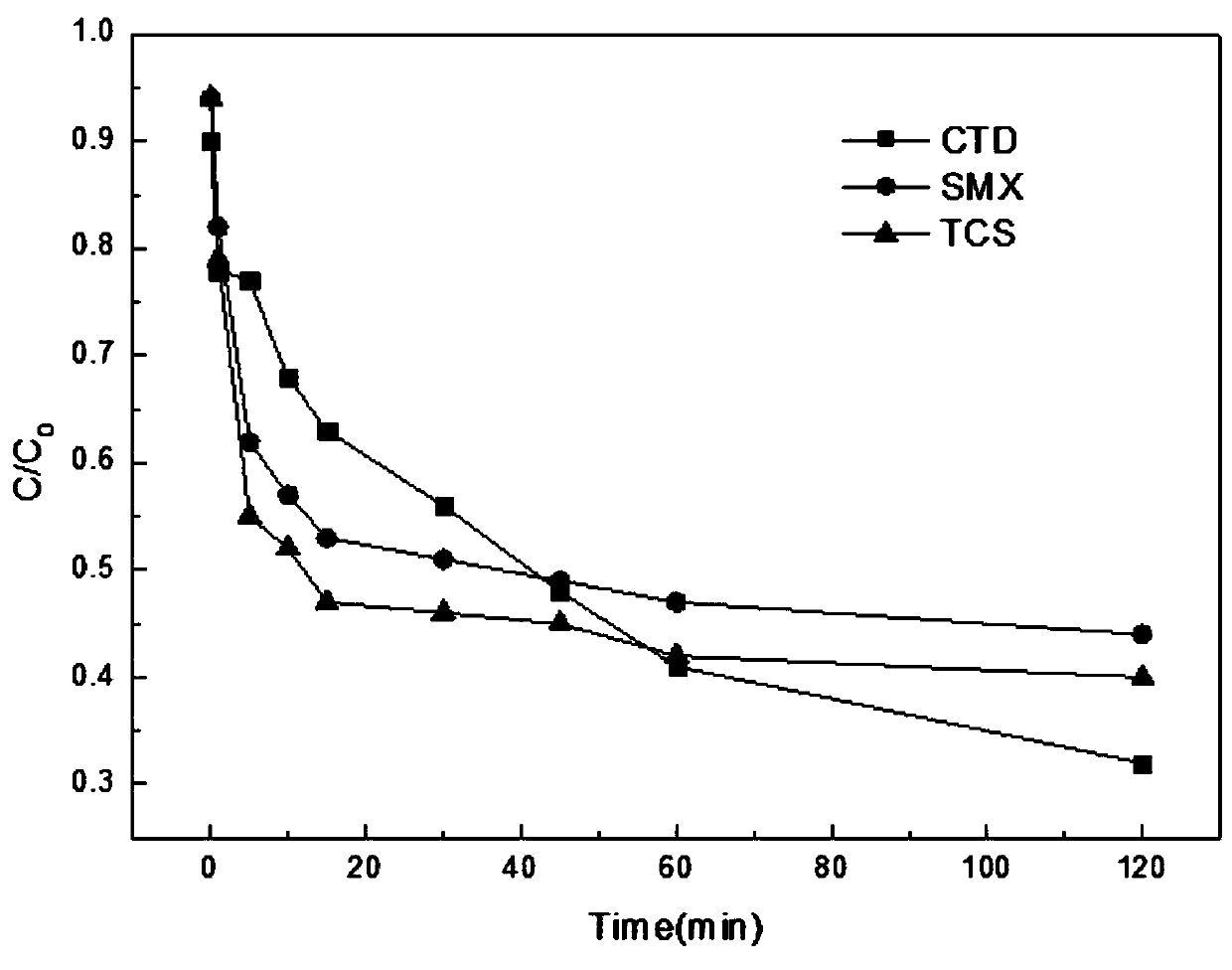

[0089] like image 3 As shown, the degradation effects of 0.06g / L and 0.08g / L on diclofenac sodium are similar, and 0.1g / L can completely degrade diclofenac sodium in 30min, and there may be adsorption. So choose 0.06g / L as the best dosage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com