Method for preparing emamectin benzoate intermediate by microreactor

A technology of microreactor and microchannel reactor, which is applied in chemical instruments and methods, preparation of sugar derivatives, sustainable manufacturing/processing, etc., can solve problems such as non-continuous production, long reaction time, and low selectivity, and achieve Increased production efficiency, high product yield, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

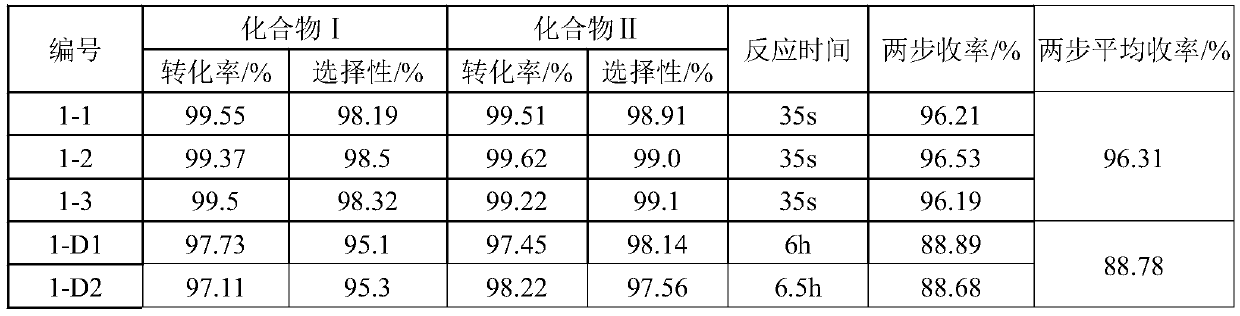

Embodiment 1

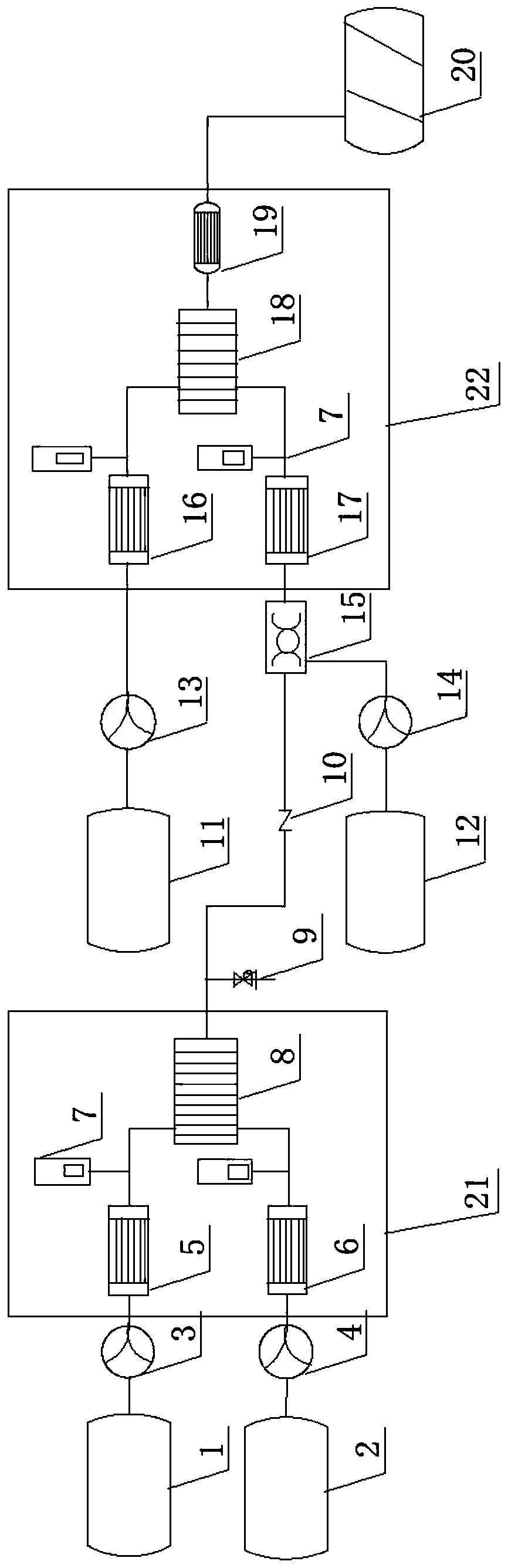

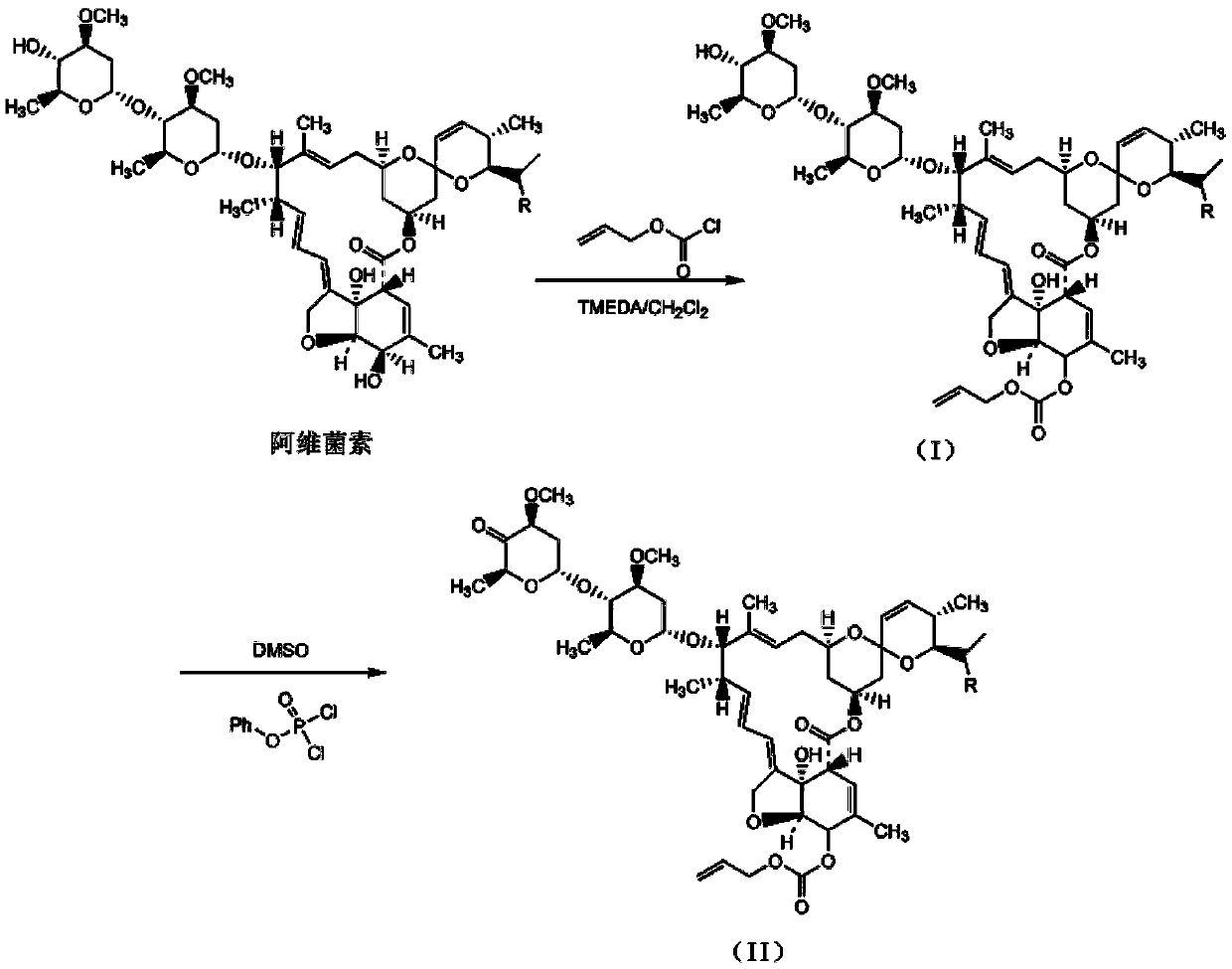

[0042] A kind of method utilizing microreactor to prepare emamectin benzoate intermediate, concrete steps are as follows:

[0043] 1) Dissolve Abamectin and Tetramethylethylenediamine in dichloromethane to form a homogeneous solution. The solution and allyl chloroformate are pumped into micro-reaction module A respectively to control Abamectin: Tetramethylethylenediamine The molar ratio of amine: dichloromethane: allyl chloroformate is 1:5:20:1.3, react at -15°C, and the residence time is 15s. Sampling and testing the reaction through the sampling valve, and compound Ⅰ is obtained after the reaction is completed ;

[0044] 2) The compound I reaction liquid flowing out in step (1) is mixed with the pumped dimethyl sulfoxide in the micro-mixer and then flows into the micro-reaction module B, where it reacts with the phenyl dichlorophosphate pumped in at the same time, and the control Abamectin: dimethyl sulfoxide: the molar ratio of phenyl dichlorophosphate is 1:2:1.3, the cont...

Embodiment 2

[0056] A kind of method utilizing microreactor to prepare emamectin benzoate intermediate, concrete steps are as follows:

[0057] 1) Dissolve Abamectin and Tetramethylethylenediamine in dichloromethane to form a homogeneous solution, and pump allyl chloroformate into micro-reaction module A at the same time to control Abamectin: Tetramethylethylenediamine The molar ratio of amine: dichloromethane: allyl chloroformate is 1:2.5:35:1.05, react at -10°C, and the residence time is 15s. Sampling and testing the reaction through the sampling valve, and compound Ⅰ is obtained after the reaction is completed ;

[0058] 2) The compound I reaction solution flowing out of step (1) is mixed with the pumped dimethyl sulfoxide in the micro-mixer and then flows into the micro-reaction module B, where it reacts with the phenyl dichlorophosphate pumped in at the same time. The molar ratio of vermectin: dimethyl sulfoxide: phenyl dichlorophosphate is 1:1.95:1.0, the reaction temperature is con...

Embodiment 3

[0070] A kind of method utilizing microreactor to prepare emamectin benzoate intermediate, concrete steps are as follows:

[0071] 1) Abamectin and tetramethylethylenediamine are dissolved in dichloromethane to form a homogeneous solution A, and solution A and allyl chloroformate are pumped into micro-reaction module A respectively to control the avermectin: tetramethyl The molar ratio of ethylenediamine: dichloromethane: allyl chloroformate is 1:3.5:35:1.07, react at a temperature of -15°C, and the residence time is 10s. Sampling and detection of the reaction is carried out through the sampling valve. After the reaction is completed, Compound I;

[0072] 2) The compound I reaction solution flowing out of step (1) is mixed with the pumped dimethyl sulfoxide in the micro-mixer and then flows into the micro-reaction module B, where it reacts with the phenyl dichlorophosphate pumped in at the same time. The molar ratio of vermectin: dimethyl sulfoxide: phenyl dichlorophosphate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com