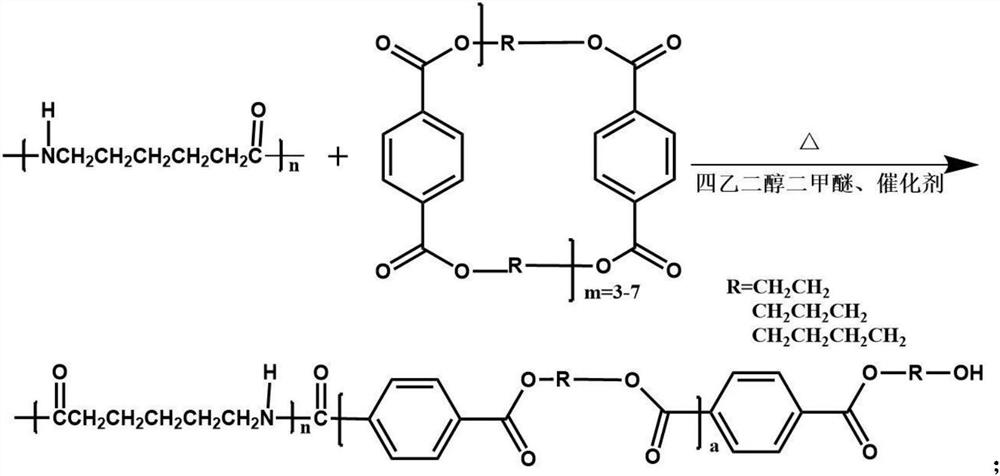

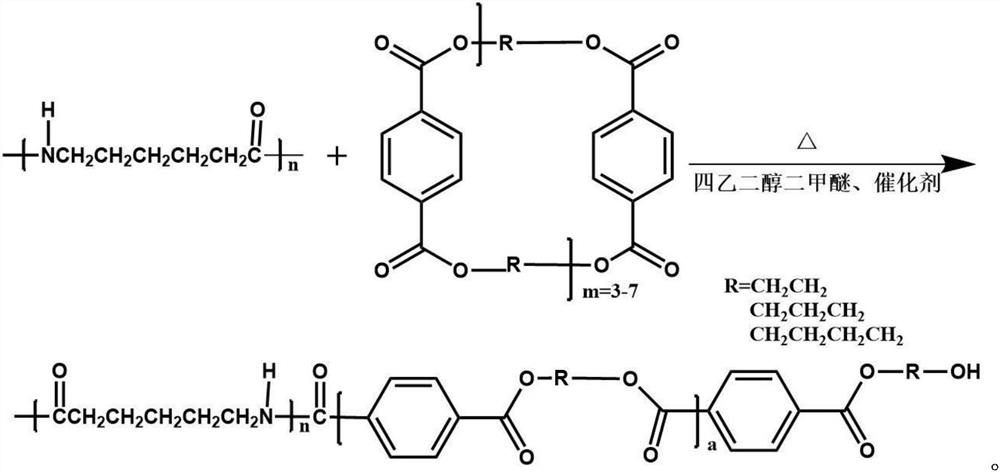

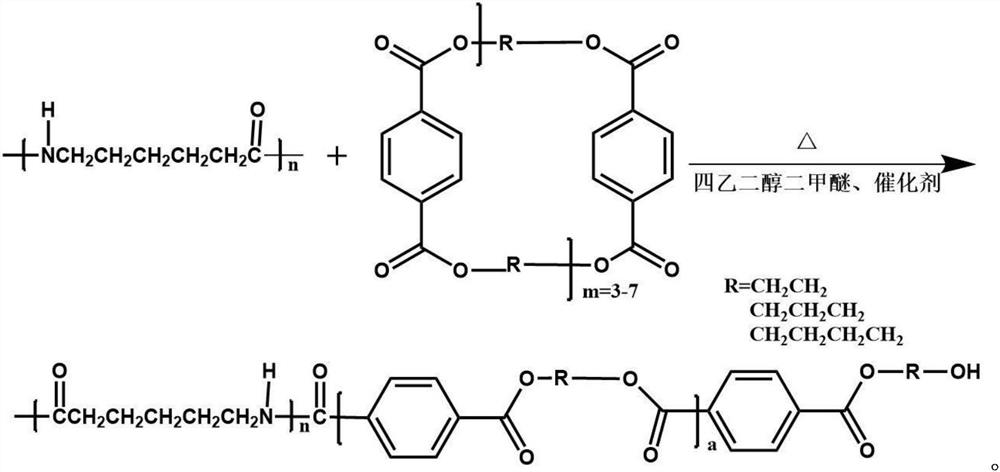

A kind of cyclic polyester modified polyamide ester and preparation method thereof

A technology of cyclic polyester and polyamide ester, which is applied in the field of chemical fiber, can solve the problems of uneven dispersion of PA6, poor product quality, yellow color, etc., achieve no reaction heat and release of by-products, simple process and equipment , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of preparation method of cyclic polyester modified polyamide ester, comprises the following steps:

[0038] 1) Under the protection of inert gas, put aliphatic polyamide and cyclic polyester into a reaction vessel and heat to 230-250°C for 10-20 minutes to melt.

[0039] 2) Add the catalyst-containing tetraethylene glycol dimethyl ether slurry, and stir at 500-1000 rpm for 10-20 minutes. Wherein, the catalyst accounts for 100-200 ppm of the total weight of the cyclic polyester, and the amount of tetraethylene glycol dimethyl ether is 1-3 percent of the total weight of the cyclic polyester.

[0040] 3) Heating reaction, carry out melt copolymerization at 250-270° C. for 10-30 minutes to obtain a melt, discharge and cool.

Embodiment 1

[0042]Put 100 parts of nylon 6 with a relative viscosity of 2 and 50 parts of cyclic polyethylene terephthalate powder in a stainless steel reactor, control the reaction temperature at 235°C, the reaction pressure at 0.25MPa, and stir at 20HZ for 20 minutes; after the reaction The catalyst is made into a slurry with tetraethylene glycol dimethyl ether, put into a reaction kettle, the temperature is controlled at 250°C, and the melt copolymerization is carried out for 20 minutes, and the obtained melt is discharged, cooled, and pelletized. In this embodiment, tetraethylene glycol dimethyl ether is 2% of the total mass of the cyclic polyester, the catalyst is ethylene glycol antimony, and the amount of the catalyst is 100 ppm of the total mass of the cyclic polyester.

Embodiment 2

[0044] Put 100 parts of nylon 6 with a relative viscosity of 2 and 60 parts of cyclic polyethylene terephthalate powder in a stainless steel reactor, control the reaction temperature at 245°C, the reaction pressure at 0.25MPa, and stir at 20HZ for 30 minutes; after the reaction The catalyst was made into a slurry with tetraethylene glycol dimethyl ether, put into a reaction kettle, the temperature was controlled at 255°C, and the melt copolymerization was carried out for 30 minutes, and the obtained melt was discharged, cooled, and pelletized. In this embodiment, tetraethylene glycol dimethyl ether is 2% of the total mass of the cyclic polyester, the catalyst is ethylene glycol antimony, and the amount of the catalyst is 150 ppm of the total mass of the cyclic polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com