Mesoporous silicon resin flame retardant, preparation method and flame-retardant composite material thereof

A technology of flame-retardant composite materials and mesoporous silicon, which is applied in the field of preparation of flame-retardant composite materials and mesoporous silicone resin flame retardants, can solve problems such as poor smoke suppression effects, and achieve improved smoke suppression effects and smoke suppression effects Good, high thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of mesoporous silicon flame retardant:

[0033] (1) Add 4.7g tetraethyl silicate, 2.5g cetyltrimethylammonium bromide, 13.2g ammonia water, 50g water and 60g ethanol to the reaction vessel, stir at room temperature for 2h, then React in the reaction kettle at 105°C for 24h, filter to obtain a white precipitate, dry at 100°C and calcinate at 550°C for 6h to obtain mesoporous silica MCM-41; add 7.2g tetraethyl silicate, 3g polycyclo Ethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, 87.5mL 2M hydrochloric acid and 22.5g water were stirred at 40°C for 20h, then reacted in a tetrafluoroethylene reactor at 100°C for 48h, The white precipitate was obtained by filtration, and after drying at 100°C, it was calcined at 550°C for 6h to obtain mesoporous silica SBA-15.

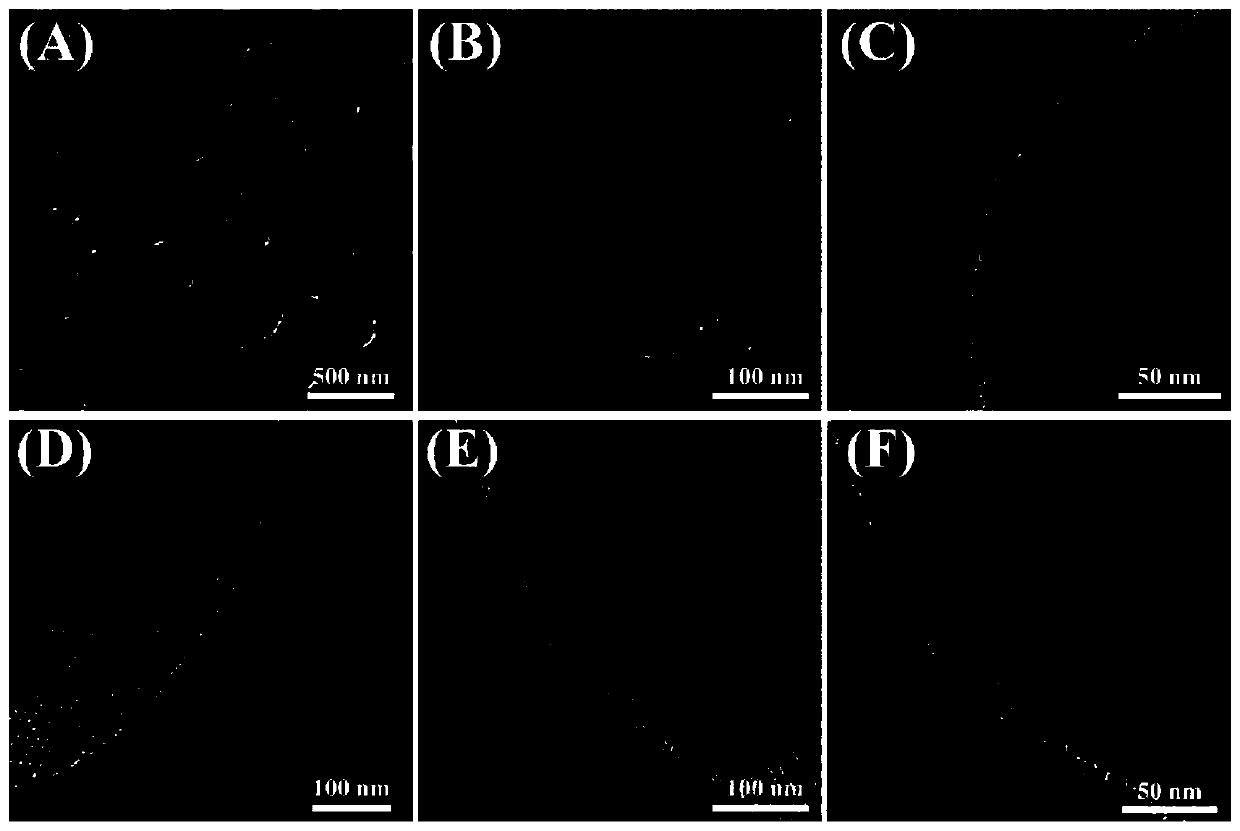

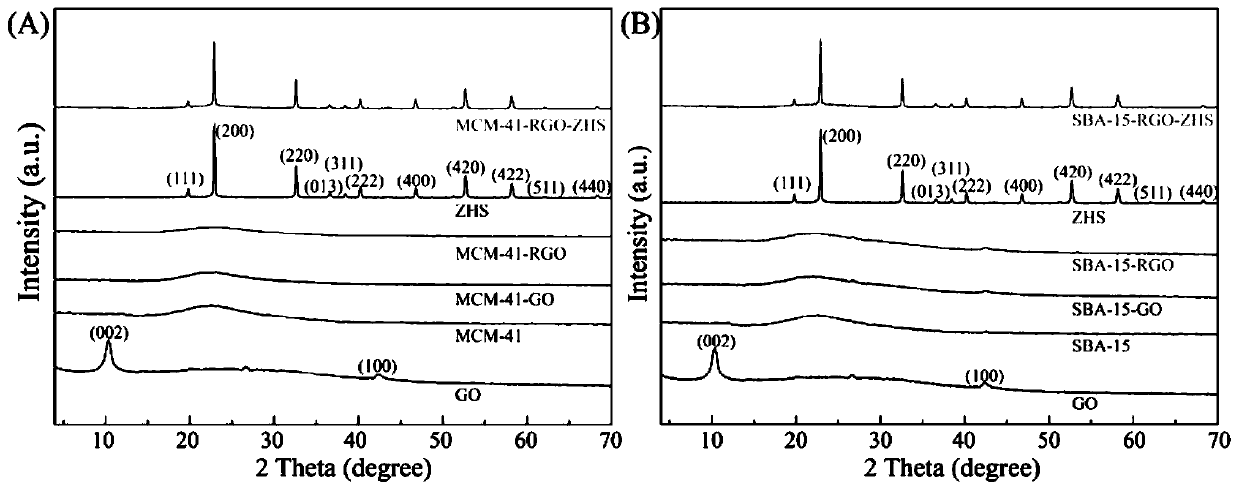

[0034] The pore structure of mesoporous silica MCM-41 and SBA-15 was observed by transmission electron microscopy, and the measured results were as follows figure 1 shown. ...

Embodiment 2

[0043] 1. Preparation of mesoporous silicon flame retardant:

[0044](1) Add 4.7g tetraethyl silicate, 2.5g cetyltrimethylammonium bromide, 13.2g ammonia water, 50g water and 60g ethanol to the reaction vessel, stir at room temperature for 2h, then React in the reaction kettle at 105°C for 24h, filter to obtain a white precipitate, dry at 100°C and calcinate at 550°C for 6h to obtain mesoporous silica MCM-41; add 7.2g tetraethyl silicate, 3g polycyclo Ethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, 87.5mL 2M hydrochloric acid and 22.5g water were stirred at 40°C for 20h, then reacted in a tetrafluoroethylene reactor at 100°C for 48h, The white precipitate was obtained by filtration, and after drying at 100°C, it was calcined at 550°C for 6h to obtain mesoporous silica SBA-15.

[0045] (2) Add 1g of mesoporous silica, 1.5g of aminopropyltriethoxysilane, 100g of water and 50g of ethanol into the reaction vessel, stir at 75°C for 24h, then add 0.99g of ...

Embodiment 3

[0051] 1. Preparation of mesoporous silicon flame retardant:

[0052] (1) Add 4.7g tetraethyl silicate, 2.5g cetyltrimethylammonium bromide, 13.2g ammonia water, 50g water and 60g ethanol to the reaction vessel, stir at room temperature for 2h, then React in the reaction kettle at 105°C for 24h, filter to obtain a white precipitate, dry at 100°C and calcinate at 550°C for 6h to obtain mesoporous silica MCM-41; add 7.2g tetraethyl silicate, 3g polycyclo Ethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, 87.5mL 2M hydrochloric acid and 22.5g water were stirred at 40°C for 20h, then reacted in a tetrafluoroethylene reactor at 100°C for 48h, The white precipitate was obtained by filtration, and after drying at 100°C, it was calcined at 550°C for 6h to obtain mesoporous silica SBA-15.

[0053] (2) Add 1g of mesoporous silica, 1g of aminopropyltriethoxysilane, 100g of water and 50g of ethanol to the reaction vessel, stir at 75°C for 24h, then add 0.55g of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com