Water-based single-component fluorocarbon paint and preparation method thereof

A single-component, fluorocarbon paint technology, applied in the field of paint chemical industry, can solve the problems of polluted environment, paint film resistance to boiling, poor gloss and color retention hardness and adhesion, waste of resources, etc., to improve the boiling resistance. , excellent film performance and environmental performance, good weather resistance and anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

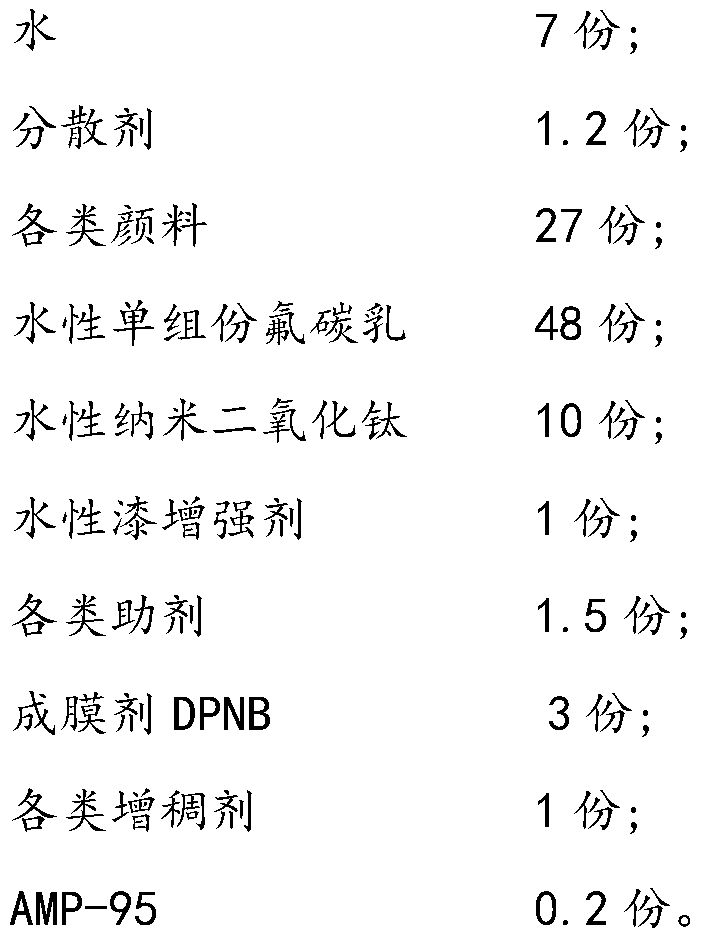

[0033] As another preferred version of the present invention, a method for preparing a water-based one-component fluorocarbon paint comprises the following steps:

[0034] Step 1: Extract water, dispersant and pigments into the container, and rotate at 4000 rpm for 30 minutes;

[0035] Step 2: When the fineness of the particles in the container is less than or equal to 20 nanometers, reduce the stirring speed, add water-based one-component fluorocarbon emulsion, water-based nano-titanium dioxide, water-based paint enhancer, various additives and film-forming agent DPNB in sequence, and then use 2000 rpm rotation for 5-10 minutes;

[0036] Step 3: After high-speed dispersion, add various thickeners through low-speed stirring to adjust the viscosity of the solution;

[0037] Step 4: Adjust the pH range of the solution to 8-9.

[0038] The emulsion adopts water-based fluorocarbon emulsion 43011 from Changxing Company in Taiwan, China. The use of water-based nano-titanium diox...

Embodiment 1

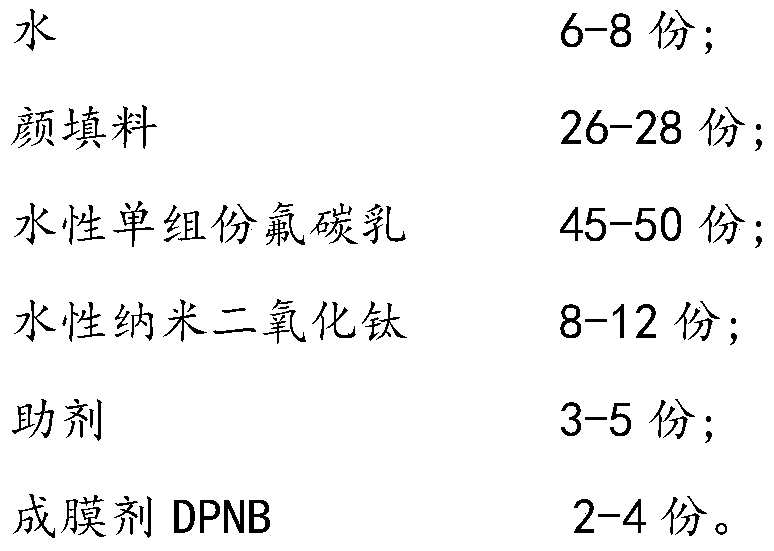

[0042] A water-based one-component fluorocarbon paint, the weight portion of the water-based one-component fluorocarbon paint comprises the following materials:

[0043]

Embodiment 2

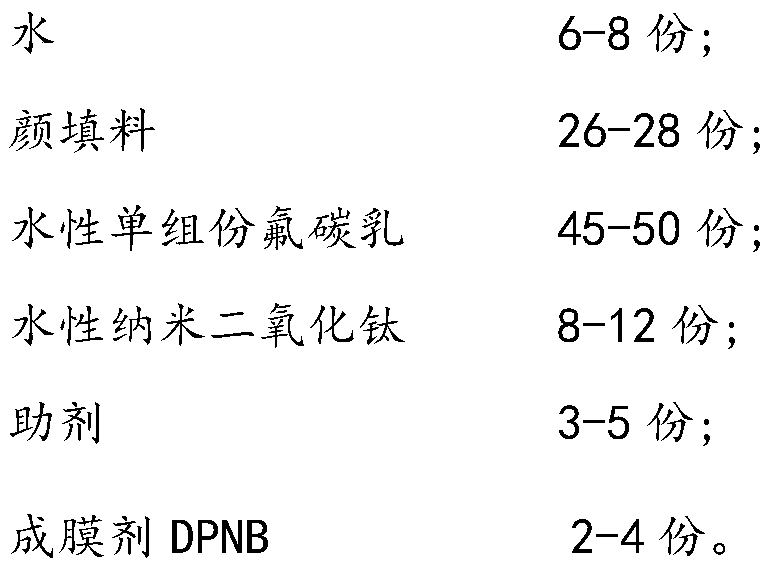

[0045] A water-based one-component fluorocarbon paint, the weight portion of the water-based one-component fluorocarbon paint comprises the following materials:

[0046]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap