Environmentally-friendly diethyl sulfate production process,

A diethyl sulfate, green production technology, applied in the direction of sulfuric acid ester preparation, organic compound preparation, chemical instruments and methods, etc., can solve the problem of inability to realize large-scale production of diethyl sulfate, low yield, large sodium sulfate and other problems, to achieve the effect of easy industrial production, lower production cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

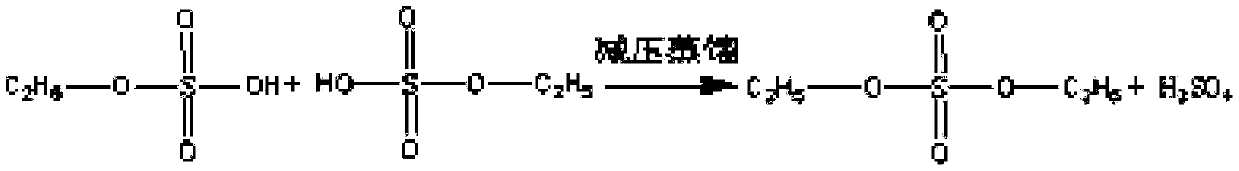

Method used

Image

Examples

Embodiment 1

[0024] Add 1000g of diethyl sulfate intermediate in the three-necked flask, and add 880g of anhydrous sodium sulfate; under stirring conditions, the temperature in the bottle is raised to 80°C for 4 hours; the temperature in the bottle is raised to 100°C, and the reaction is for 8 hours; Put the flask into cold water and cool down to 0°C in the bottle; add 900g of water at a temperature of 10°C and stir to dissolve. After all the dissolution in the bottle, let stand and separate the liquids to obtain 398.1g of the upper ester phase (crude diethyl sulfate); the crude product After re-distillation, 382.2 g of diethyl sulfate was obtained, with a yield of 68.5% (calculated as ethanol). The purity was 99.82% as detected by gas chromatography.

Embodiment 2

[0026] Add 50kg of diethyl sulfate intermediate in the reaction kettle, add 22kg of anhydrous sodium sulfate; under the condition of stirring, the temperature in the kettle is raised to 60°C for 2 hours; the temperature in the kettle is raised to 90°C, and the reaction is for 2 hours; ℃, react for 2 hours; after the reaction is completed, cool to 20 ℃ in the kettle; add 60 kg of water with a temperature of 5 ℃ and stir to dissolve, and after all the dissolution in the kettle, stand still and separate liquids to obtain 20.78 kg of the upper ester phase; the obtained ester After phase distillation, 19.95kg of diethyl sulfate was obtained, with a yield of 71.5% (in terms of ethanol), and detected by gas chromatography, the purity was 99.76%.

Embodiment 3

[0028] Add 2000kg of diethyl sulfate intermediate in the reaction kettle, add 700kg of anhydrous sodium sulfate; under stirring conditions, the temperature in the kettle is raised to 90°C for 2 hours; the temperature in the kettle is raised to 130°C, and the reaction is for 2 hours; after the reaction is completed, cool to 50°C in the kettle; add 3,000kg of water at a temperature of 10°C and stir to dissolve, and after all the dissolution in the kettle, stand still and separate liquids to obtain 785.8kg of the upper ester phase; obtain 754.4kg of diethyl sulfate after distillation of the obtained ester phase, The yield is 67.6% (calculated as ethanol), and the purity is 99.84% as detected by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com