UV-OCA adhesive for TAC film bonding and preparation method thereof

A UV-OCA and film bonding technology, which is applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems that the development of adhesives is in a blank stage, and achieve the effects of rapid curing, improved production efficiency, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

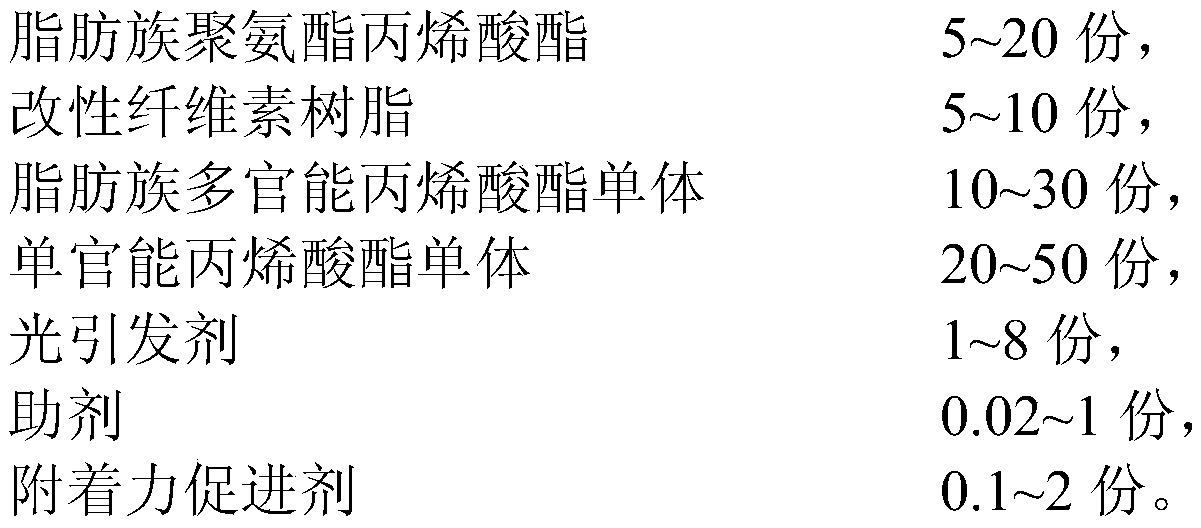

Method used

Image

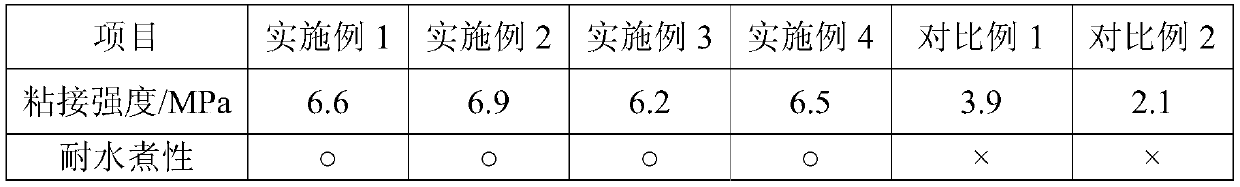

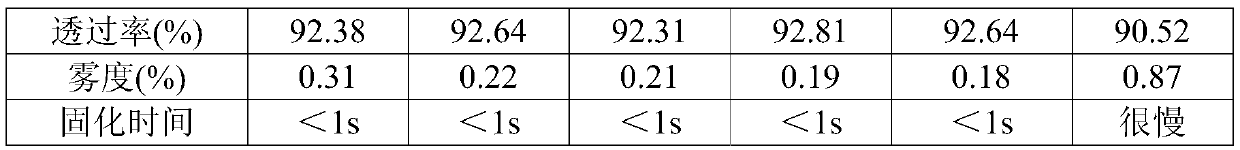

Examples

Embodiment 1

[0027] A preparation method for a UV-OCA adhesive for TAC film bonding, comprising the following steps:

[0028] (1) 8g UV-curable cellulose resin JS-113, 15g hexanediol diacrylate (HDDA), 20g tripropylene glycol diacrylate (TPGDA), 25g acryloylmorpholine (ACMO) and 8g isoborneol Acrylic acid ester (IBOA) was mixed, and stirred at a speed of 2000rpm for 1 hour to make a homogeneous composition;

[0029] (2) Add 20g resin 2230 (Wuxi Boqiang), 3g photoinitiator TPO, 0.05g defoamer BYK-014, 0.95g adhesion promoter PM-2 to the above composition and continue stirring for 30min to make an adhesive.

[0030] (3) The prepared adhesive uses a laminating machine to bond two layers of untreated TAC film with a thickness of 200 μm, and then uses a high-pressure mercury lamp for ultraviolet (UV) irradiation, the irradiation height is 50mm, the conveyor belt speed is 10m / min, and the light energy 200mJ / cm 2 , to obtain samples for evaluation.

Embodiment 2

[0032] A preparation method for a UV-OCA adhesive for TAC film bonding, comprising the following steps:

[0033] (1) Mix 15g UV-curable cellulose resin JS-113, 15gHDDA, 13gTPGDA, 25g ACMO and 8g IBOA, and stir at 2000rpm for 1 hour to make a uniform composition;

[0034] (2) Add 20g resin 2230 (Wuxi Boqiang), 3g photoinitiator TPO, 0.05g BYK-014, 0.95g PM-2 to the above composition and continue stirring for 30min to make an adhesive;

[0035] (3) The prepared adhesive uses a laminating machine to bond two layers of untreated TAC films with a thickness of 200 μm, and then uses a high-pressure mercury lamp for UV irradiation, with an irradiation height of 50mm, a conveyor belt speed of 10m / min, and an illumination energy of 200mJ / cm 2 , to obtain samples for evaluation.

Embodiment 3

[0037] A preparation method for a UV-OCA adhesive for TAC film bonding, comprising the following steps:

[0038] (1) Mix 8g UV-curable cellulose resin JS-113, 25gHDDA, 20g TPGDA, 25g ACMO and 8g IBOA, and stir at 2000rpm for 1 hour to make a uniform composition;

[0039] (2) Add 10g resin 2230 (Wuxi Boqiang), 3g photoinitiator TPO, 0.05g BYK-014, 0.95g PM-2 to the above composition and continue stirring for 30min to make an adhesive;

[0040] (3) The prepared adhesive uses a laminating machine to bond two layers of untreated TAC films with a thickness of 200 μm, and then uses a high-pressure mercury lamp for UV irradiation, with an irradiation height of 50mm, a conveyor belt speed of 10m / min, and an illumination energy of 200mJ / cm 2 , to obtain samples for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com