Preparation method of tin nanoparticles and lithium ion battery negative electrode material

A nanoparticle and precursor technology, applied in the nanometer field, can solve the problems of uniformity, inability to effectively prepare particle size, etc., and achieve the effect of simple method, simple operation and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

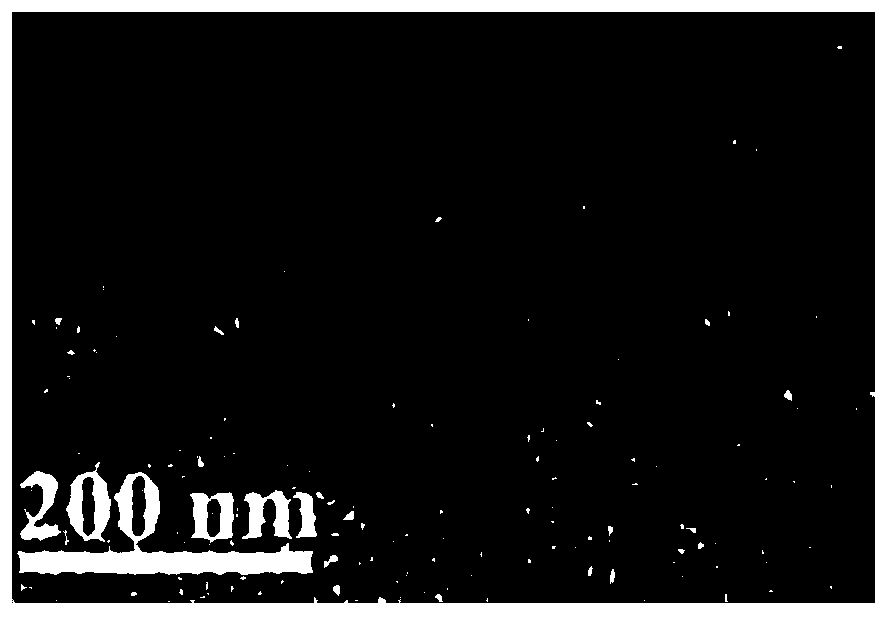

Image

Examples

preparation example Construction

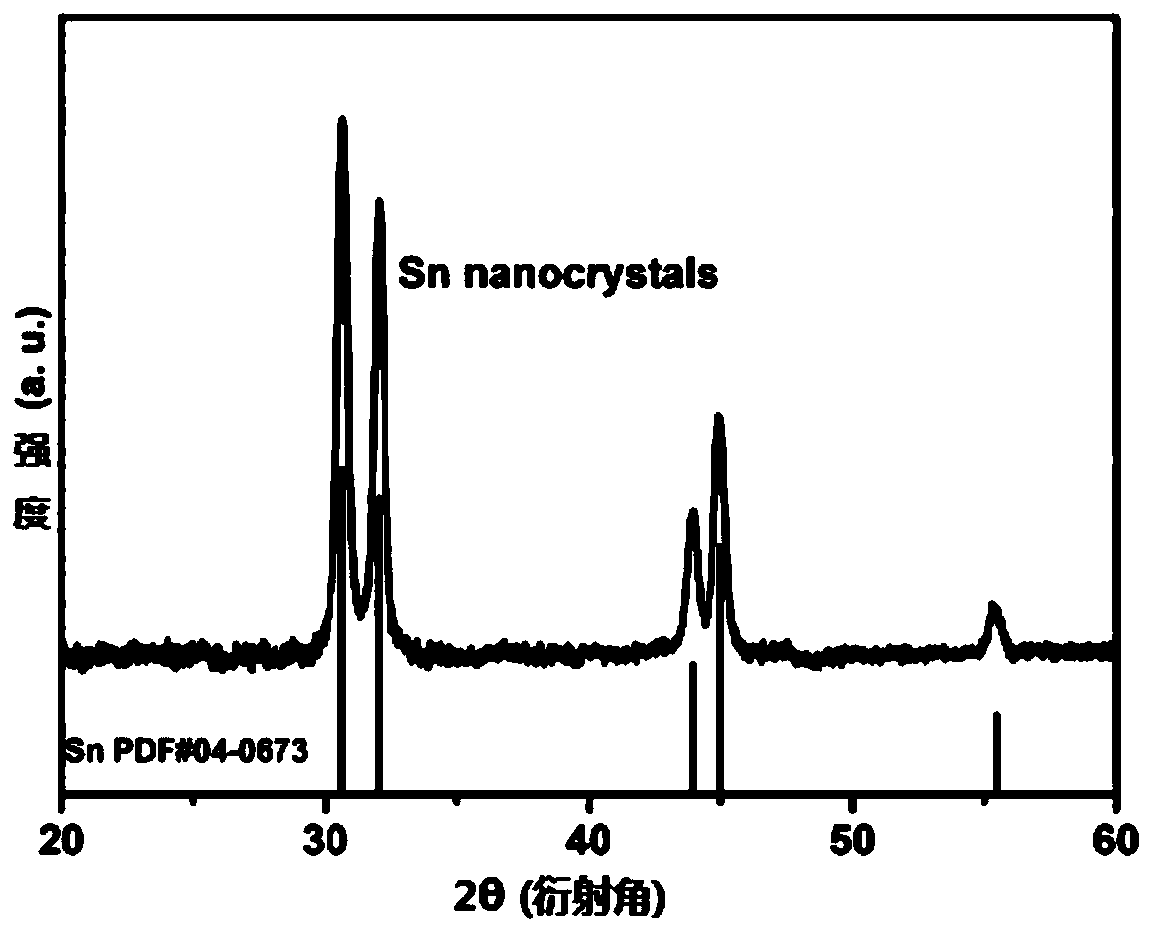

[0023] A method for preparing a quantum dot material, comprising the steps of:

[0024] S01. Provide tin precursors, tungsten hexacarbonyl, oleylamine, hexamethyldisilazane and non-coordinating solvents;

[0025] S02, in an inert atmosphere, dissolve the tin precursor, the tungsten hexacarbonyl, the oleylamine and the hexamethyldisilazane in the non-coordinating solvent to obtain a mixture; then, The mixture is heated to obtain the tin nanoparticles.

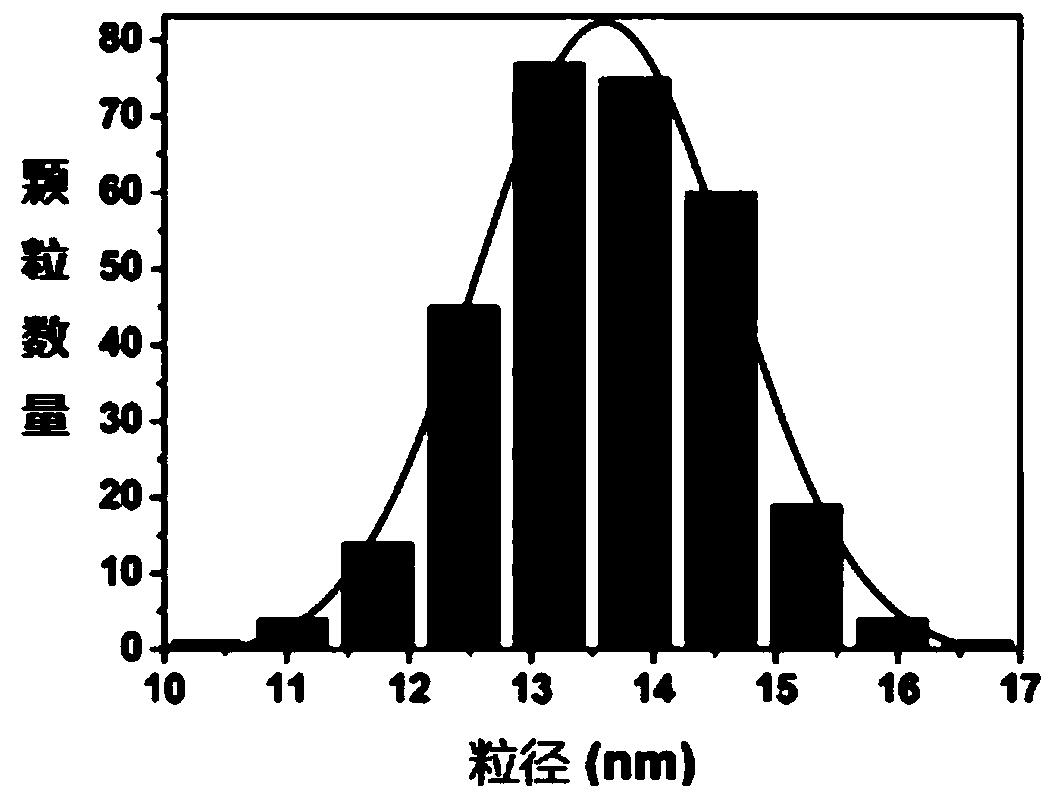

[0026] The preparation method of tin nanoparticles provided in the embodiment of the present invention uses tungsten hexacarbonyl as a reducing agent, oleylamine and hexamethyldisilazane as a ligand, and a non-coordinating solvent as a reaction solvent. Under this condition, tin nanoparticles with uniform particle size and small size are prepared, the particle size distribution is narrow, and the standard deviation of the average particle size is only 6%-8%. The method is simple and easy to operate, and each reaction raw mater...

Embodiment 1

[0046] The present embodiment has prepared a kind of preparation method of tin nanoparticle, specifically comprises the following steps:

[0047] Weigh 40 mg of stannous chloride (99% analytically pure, Alfa Aesar) in the glove box and put it into a glass bottle, then add oleylamine (1 mL, 70% analytically pure, Aldrich) and 1 - Octadecene (ODE, 9 mL, 90% analytically pure, Aldrich), sealed and sonicated until a white suspension was obtained. Then, take a three-necked flask and add 10 mg tungsten carbonyl (W(CO) 6 , 97% analytically pure, Alfa Aesar), select a suitable condenser tube, heating mantle, thermocouple and rubber stopper, and seal the reaction device well. Then vacuumize the inside of the bottle for 1 hour, then fill it with Ar gas, inject the suspension after ultrasonication and 0.75mL hexamethyldisilazane (HMDS, 99% analytically pure, Aldrich) into the three-necked bottle, press 10 ℃ Heat to 60°C at a heating rate of 10°C / min and keep it for about 10 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com