Proton exchange membrane electrode, fuel cell, galvanic pile, and manufacturing method of cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of inability to manufacture hydrogen-oxygen battery stacks, reduce strength, and metal corrosion, so as to promote commercialization The effect of development, high power-to-weight ratio, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Example 1: Solid-state heat-conducting proton exchange membrane fuel cell stack

[0114] Heat dissipation is one of the core problems faced by the proton exchange membrane battery stack. This embodiment uses a solid high thermal conductivity film material to export the reaction heat of the hydrogen-oxygen reaction from the inside of the stack to the surroundings of the stack, and then exchange heat through air or liquid The device dissipates heat.

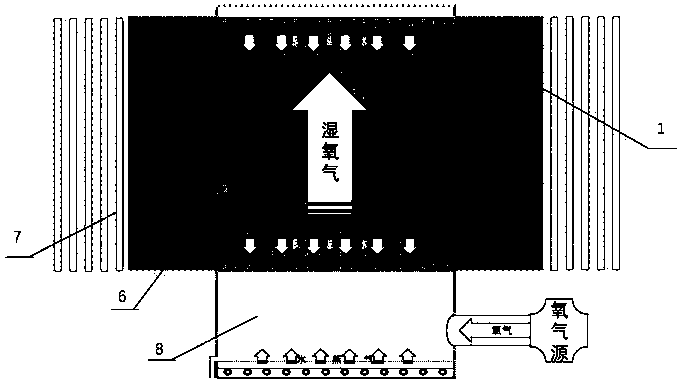

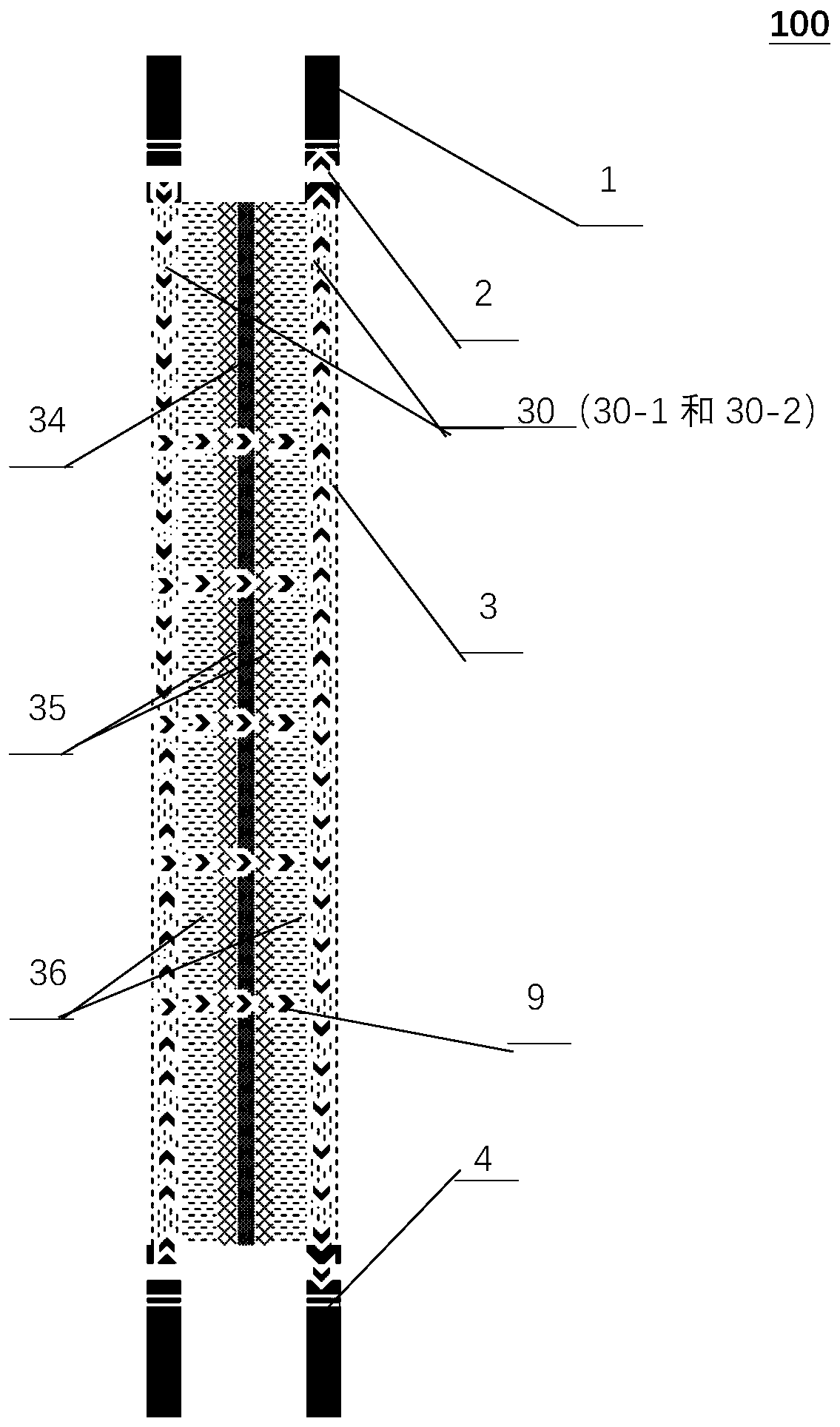

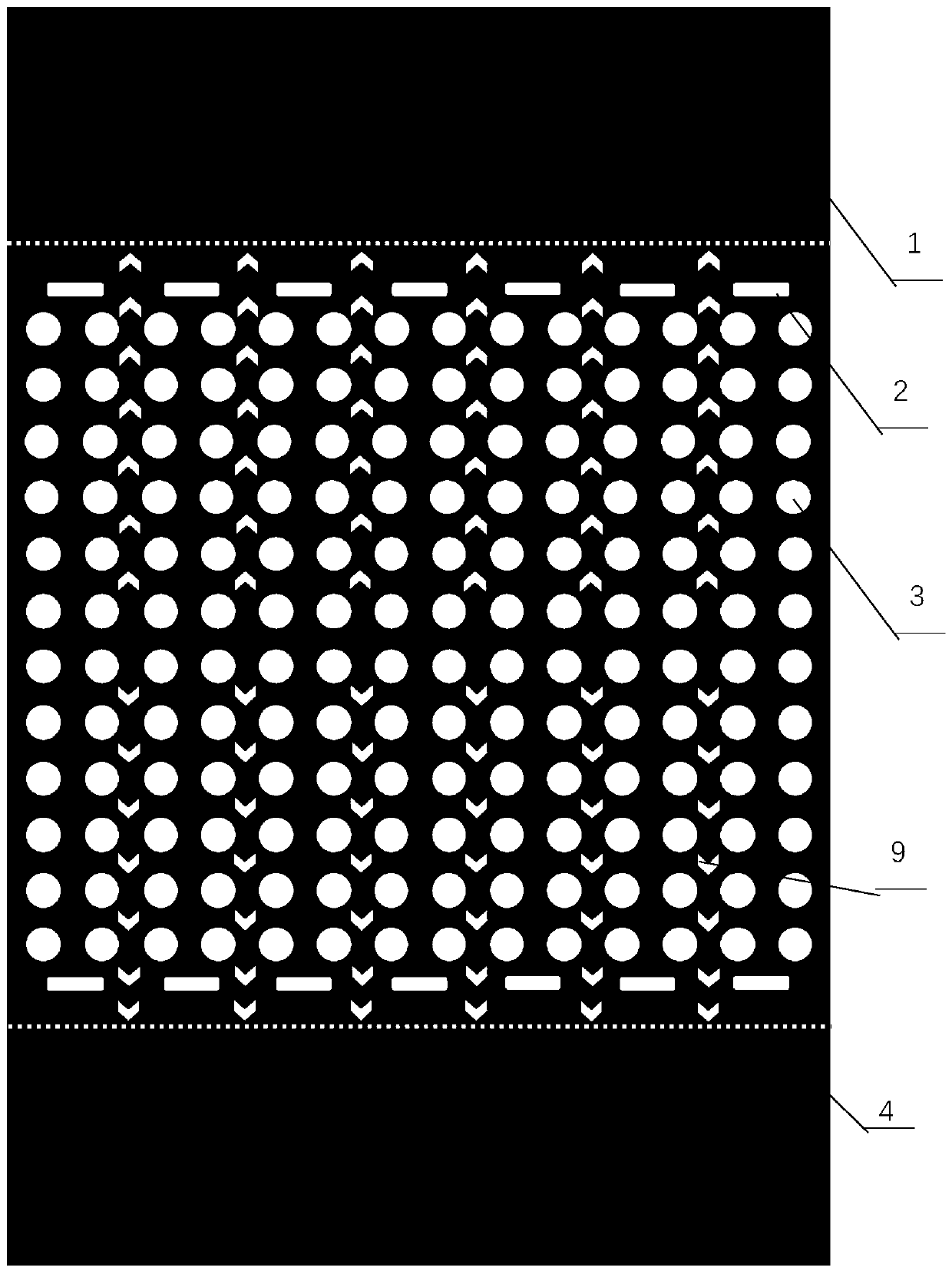

[0115] Figure 6 and Figure 7 It shows a high thermal conductivity proton exchange membrane fuel cell stack and its liquid cooling device, in which 7 indicates the cooling device outside the stack, and 8 indicates the filtering and humidifying device. in Figure 6 A view of the hydrogen flow field is shown, in which the liquid heat dissipation device is around the heat dissipation part of the high-conductivity heat-conducting film, and performs heat exchange with the heat dissipation part, thereby dissipating the hydroge...

Embodiment 2

[0117] Example 2: Bypass Conductive Proton Exchange Membrane Fuel Cell Stack

[0118] High electrical conductivity is another core issue faced by proton exchange membrane battery stacks. Generally speaking, the internal current of a proton exchange membrane battery stack is extremely high when generating electricity. For example, a small electric stack with a generating power of tens of kilowatts has an internal current of hundreds of amperes, which requires the flow field plate to have excellent electrical conductivity. , extremely low internal resistance. The current flow field plate material that meets this requirement is high-purity graphite, but it is difficult to manufacture and dissipate heat. For the metal flow field plate proton exchange membrane battery stack, the hydrogen required for the hydrogen-oxygen reaction will cause hydrogen corrosion to many metals, and the hydrogen ions generated in the hydrogen-oxygen reaction will react with the metal, corroding the met...

Embodiment 3

[0121] Embodiment 3: Solid-state heat-conducting proton exchange membrane fuel cell stack

[0122] With the development of material science and technology, the film surface of the new material of conductive and heat-conducting film can have excellent properties of high electrical conductivity and high thermal conductivity at the same time, so that the local heat and electricity on the surface of the film can quickly spread to the entire surface. The present invention adopts a new solid high-conductivity and high-thermal-conduction film material to quickly export the reaction heat of the hydrogen-oxygen reaction from the inside of the stack to the surroundings of the stack, and then dissipate heat through the air or liquid heat exchange device. At the same time, the high-conductivity heat-conducting film guides the current generated by the hydrogen-oxygen reaction from the inside of the stack to the surroundings of the stack, and then conducts the current through the bypass circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com