All-solid-state sodium-sulfur battery and preparation method thereof

A sodium-sulfur battery, all-solid-state technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of unsatisfactory electrochemical performance, limited lithium resource reserves, complicated preparation process, etc., and achieve the suppression of polysulfides Shuttle effect, excellent electrochemical performance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

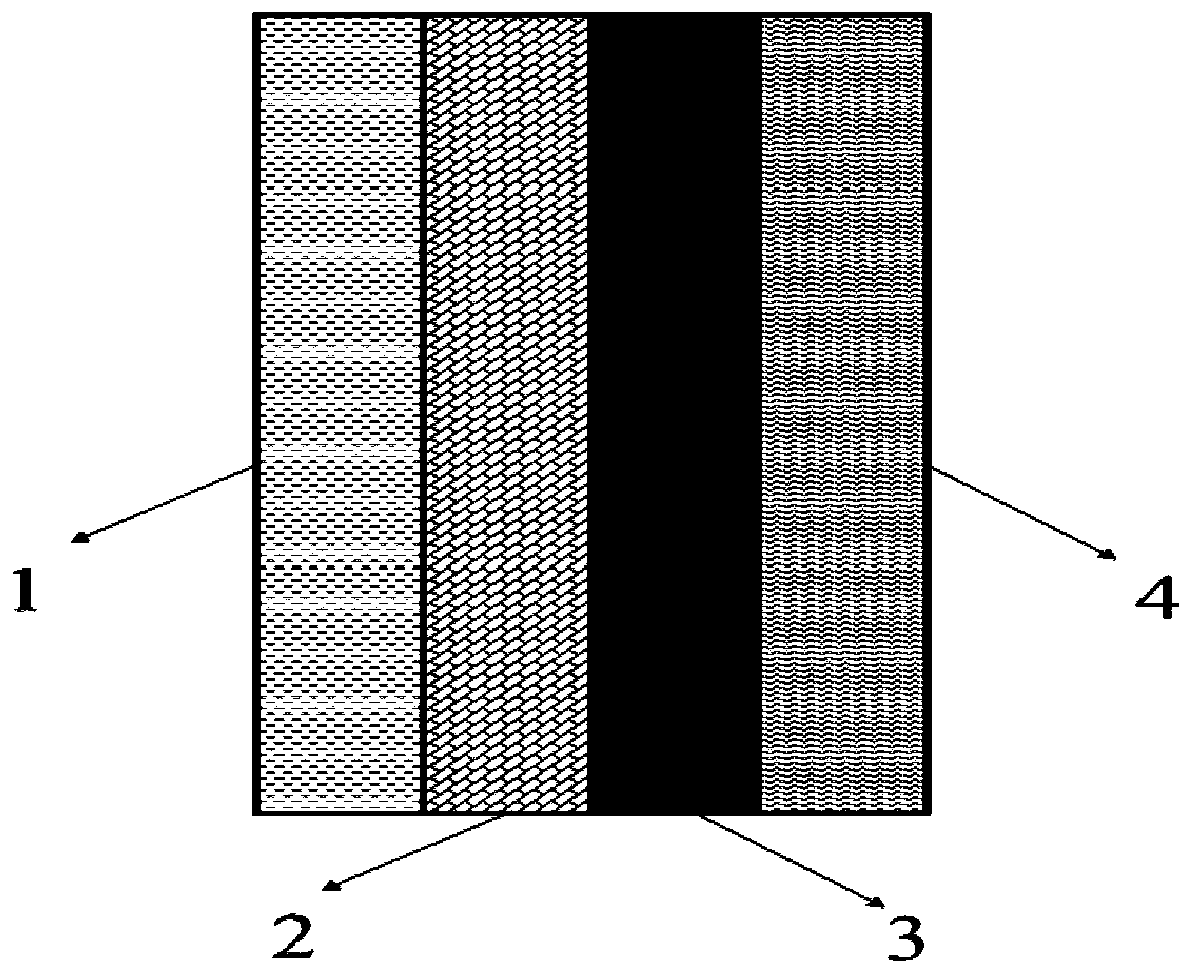

[0027] refer to figure 1 , The all-solid-state sodium-sulfur battery provided by the embodiment of the present invention includes: a positive electrode current collector 1, a positive electrode active material layer 2, an all-solid electrolyte layer 3, and a battery negative electrode 4; the positive electrode current collector 1 is a metal foil, a metal alloy or a metal One of the composites; the positive electrode active material layer 2 is a silicate material or a sulfur-carbon composite material; the all-solid electrolyte layer 3 can be dissociated into a composite material of anions and cations; wherein, the positive electrode active material layer includes materials that can allow sodium ions to be freely adsorbed and the extracted material; the negative electrode active material 4 of the battery is metal sodium or an alloy material.

[0028] The battery anode material and solid electrolyte provided by the embodiments of the present invention can effectively adsorb polys...

Embodiment 2-26

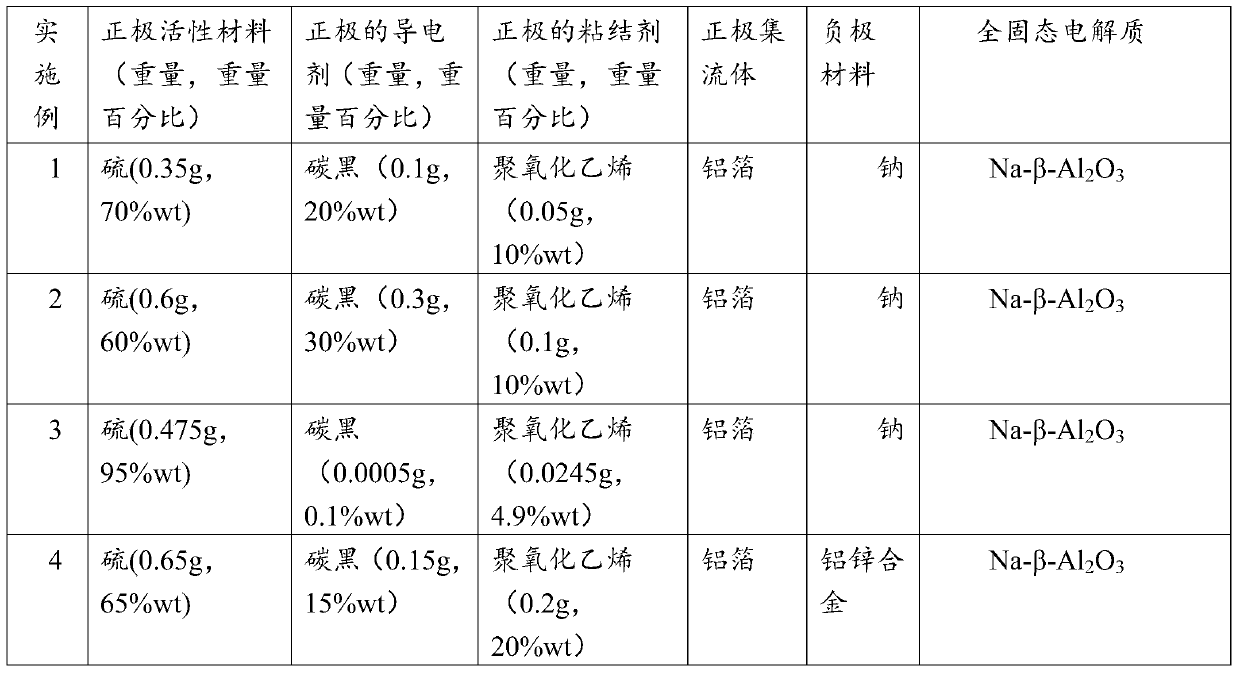

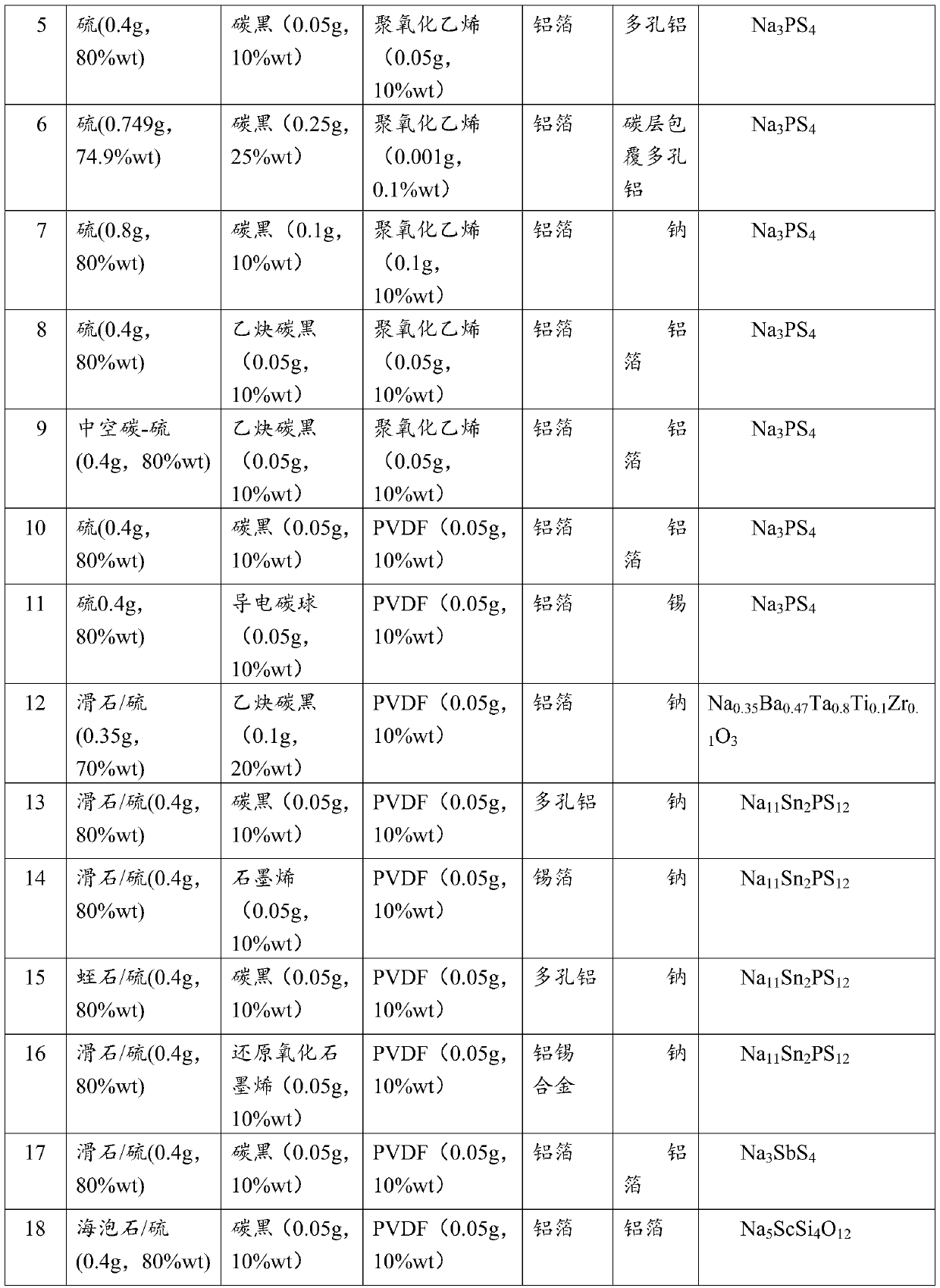

[0035] Examples 2-26 and Example 1 The sodium-sulfur battery preparation process steps are the same as Example 1, the difference lies in the different preparation materials or material content, see Table 1 for details.

[0036] Table 1 Example 1-26 Negative electrode material, positive electrode material and solid electrolyte layer comparison

[0037]

[0038]

[0039]

[0040] The form of the all-solid-state sodium-sulfur battery involved in the present invention is not limited to the button battery, and can also be designed into a flat battery, a cylindrical battery and the like according to the core components. The main active components of the sodium ion super battery proposed by the present invention are the positive electrode material capable of adsorbing polysulfides and the electrolyte material capable of transporting sodium ions well between the electrode and the electrolyte interface.

[0041] The positive electrode material and solid electrolyte proposed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com