Synthesis method of release-type xylose ester fragrance for tobacco flavoring

A technology of tobacco flavoring and synthesis method, which is applied in the direction of essential oils/flavors, tobacco, and processed tobacco. It can solve the problems of inability to obtain xylose ester flavor compounds and restrictions, and achieve pure and rich aftertaste, increased aroma, and coordination. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

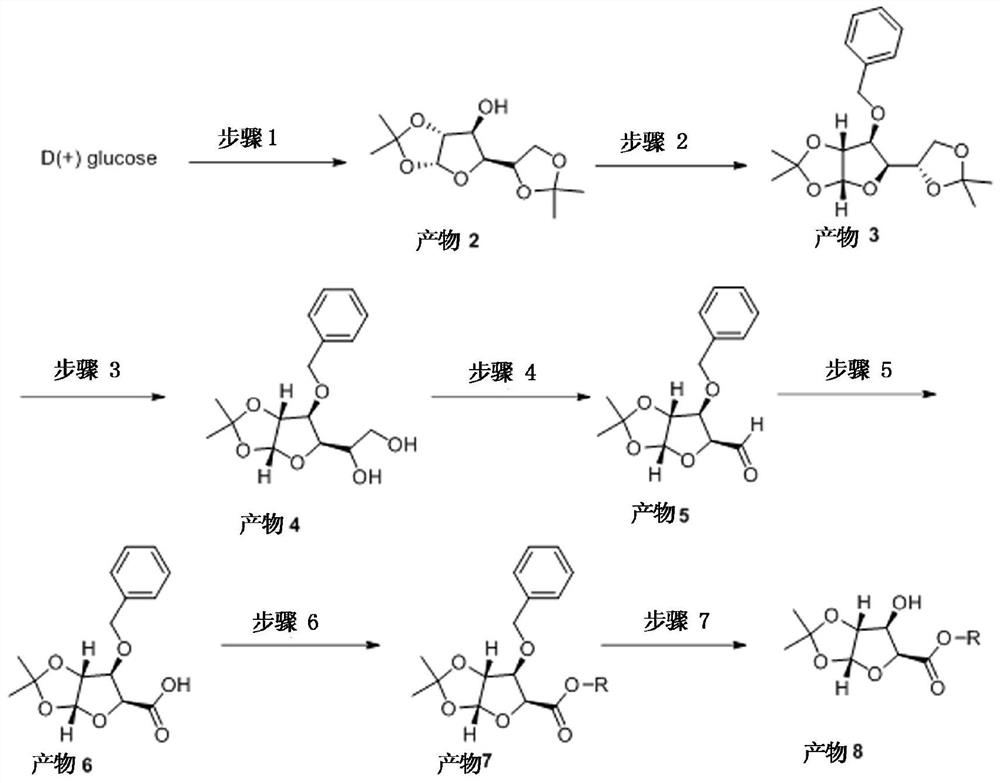

[0027] The release type xylose ester perfume synthesis method for tobacco flavoring is characterized in that: comprising the following steps:

[0028] Step 1: 15g (D+) glucose, 150mL of anhydrous acetone, 1.25g of anhydrous copper sulfate (CuSO 4 ), 0.75g concentrated sulfuric acid (H 2 SO 4 ) was placed in a 500mL single-necked flask and stirred at room temperature with a stirrer for 48h, concentrated in vacuo, and the crude product oil obtained was washed with 80mL of saturated sodium bicarbonate (NaHCO 3 ) washing, 50mL ethyl acetate (EtOAc) extraction twice, combined organic phase, and with anhydrous sodium sulfate (Na 2 SO 4 ) and finally concentrated in vacuo to obtain 18.95 g of white solid product 2: (3aR,5S,6S,6aR)-5-((S)-2,2-dimethyl-1,3-dioxolane-4- base)-2,2-dimethyltetrahydrofuran[2,3-d][1,3]dioxolan-6-ol; and the yield of product 2 was 95.3%; the structural characterization of product 2: HR -MS m / z:260.2,[M+H] + .

[0029] Step 2: Take 3.5g of product 2 an...

Embodiment 2

[0042] The release type xylose ester perfume synthesis method for tobacco flavoring is characterized in that: comprising the following steps:

[0043] Step 1: 18g (D+) glucose, 180mL of anhydrous acetone, 1.58g of anhydrous copper sulfate (CuSO 4 ), 0.98g concentrated sulfuric acid (H 2 SO 4 ) was placed in a 500mL single-necked flask and stirred at room temperature with a stirrer for 48h, concentrated in vacuo, and the crude product oil obtained was washed with 100mL of saturated sodium bicarbonate (NaHCO 3 ) washing, 70mL ethyl acetate (EtOAc) extraction twice, combined organic phase, and with anhydrous sodium sulfate (Na 2 SO 4 ) and finally concentrated in vacuo to obtain 24.8 g of white solid product 2: (3aR,5S,6S,6aR)-5-((S)-2,2-dimethyl-1,3-dioxolane-4- base)-2,2-dimethyltetrahydrofuran[2,3-d][1,3]dioxolan-6-ol; and the yield of product 2 was 95.3%; and the yield of product 2 was 95.3%; Structural characterization: HR-MS m / z: 260.2, [M+H] + .

[0044] Step 2: Tak...

Embodiment 3

[0057] The release type xylose ester perfume synthesis method for tobacco flavoring is characterized in that: comprising the following steps:

[0058] Step 1: 20g (D+) glucose, 200mL of anhydrous acetone, 1.82g of anhydrous copper sulfate (CuSO 4 ), 2.25g concentrated sulfuric acid (H 2 SO 4 ) was placed in a 500mL single-necked flask and stirred at room temperature with a stirrer for 48h, concentrated in vacuo, and the obtained crude product oil was washed with 120mL of saturated sodium bicarbonate (NaHCO 3 ) washing, 95mL ethyl acetate (EtOAc) extraction twice, combined organic phase, and with anhydrous sodium sulfate (Na 2 SO 4 ) and finally concentrated in vacuo to give 28 g of white solid product 2: (3aR,5S,6S,6aR)-5-((S)-2,2-dimethyl-1,3-dioxolan-4-yl )-2,2-dimethyltetrahydrofuran[2,3-d][1,3]dioxolan-6-ol; and the yield of product 2 was 95.3%; structural characterization: HR-MS m / z:260.2,[M+H] + .

[0059] Step 2: Take 7.2g of product 2 and 70mL of anhydrous N,N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com