Preparation method and application of MgCl2/silica gel carrier-supported metallocene catalyst

A metallocene catalyst and carrier-supported technology, which is applied in the field of polyolefin preparation, can solve problems such as difficult processing and low heat-sealing temperature, and achieve the effects of good processing performance, high activity and improved catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] MgCl 2 / Silica gel carrier loaded metallocene catalyst, the preparation method is as follows:

[0029] 1)MgCl 2 / Preparation and activation of silica gel support:

[0030] The 955 silica gel was calcined at 500° C. for 3 h under the protection of nitrogen to obtain activated 955 silica gel.

[0031] Take 50g MgCl 2 Dissolve in 300mL tetrahydrofuran, add 300g activated 955 silica gel, react at 30°C for 2h, filter to obtain MgCl 2 / Silicone carrier. MgCl will be obtained 2 / The silica gel carrier was calcined at 500°C for 3h to obtain activated MgCl 2 / Silicone carrier.

[0032] 2) After passing nitrogen into the 250ml reaction flask for 3-5 times, add 30g of the activated MgCl obtained in step 1) 2 / silica gel carrier, add 50mL toluene, heat up to 50°C, add 50mL of MAO toluene solution (containing MAO 15g) dropwise, react at 50°C for 4 hours, filter, and wash with 50mL toluene 3 times to obtain a supported cocatalyst slurry.

[0033] 3) Introduce nitrogen in...

Embodiment 2

[0035] MgCl 2 / Silica gel carrier loaded metallocene catalyst, the preparation method is as follows:

[0036] 1)MgCl 2 / Preparation and activation of silica gel support:

[0037] The 955 silica gel was calcined at 500° C. for 3 h under the protection of nitrogen to obtain activated 955 silica gel.

[0038] Take 50g MgCl 2 Dissolve in 300mL tetrahydrofuran, add 300g activated 955 silica gel, react at 30°C for 2h, filter to obtain MgCl 2 / Silicone carrier. MgCl will be obtained 2 / The silica gel carrier was calcined at 500°C for 3h to obtain activated MgCl 2 / Silicone carrier.

[0039] 2) After passing nitrogen into the 250ml reaction flask for 3-5 times, add 30g of the activated MgCl obtained in step 1) 2 / silica gel carrier, add 50mL toluene, heat up to 50°C, add dropwise 50mL of MAO toluene solution (containing MAO 15g), react at 50°C for 4 hours, filter, and wash with 50mL toluene 3 times to obtain a supported cocatalyst slurry.

[0040] 3) Nitrogen was introduce...

Embodiment 3-6

[0042] Polyethylene synthetic method, step is as follows:

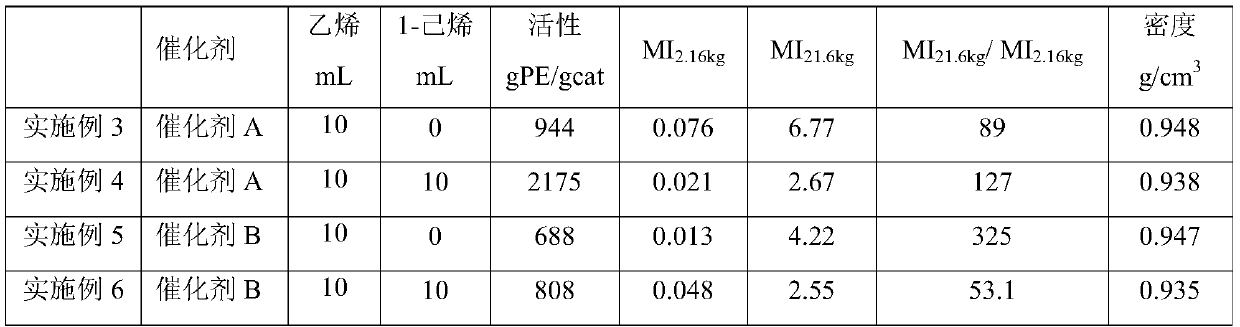

[0043] In a 2L stainless steel autoclave, first pass in nitrogen for replacement 3-5 times, then pass in ethylene for replacement 3-5 times, then add 1L of n-hexane, 10g of polyethylene monomer as a seed, 10mmol of triethylaluminum , add catalyst, ethylene and 1-hexene as in Table 1, and react at 1.0 MPa and 90° C. for 1 hour. After the reaction, cool down, filter, and dry to obtain polyethylene powder. The results are shown in Table 1.

[0044] Table 1 aggregated data

[0045]

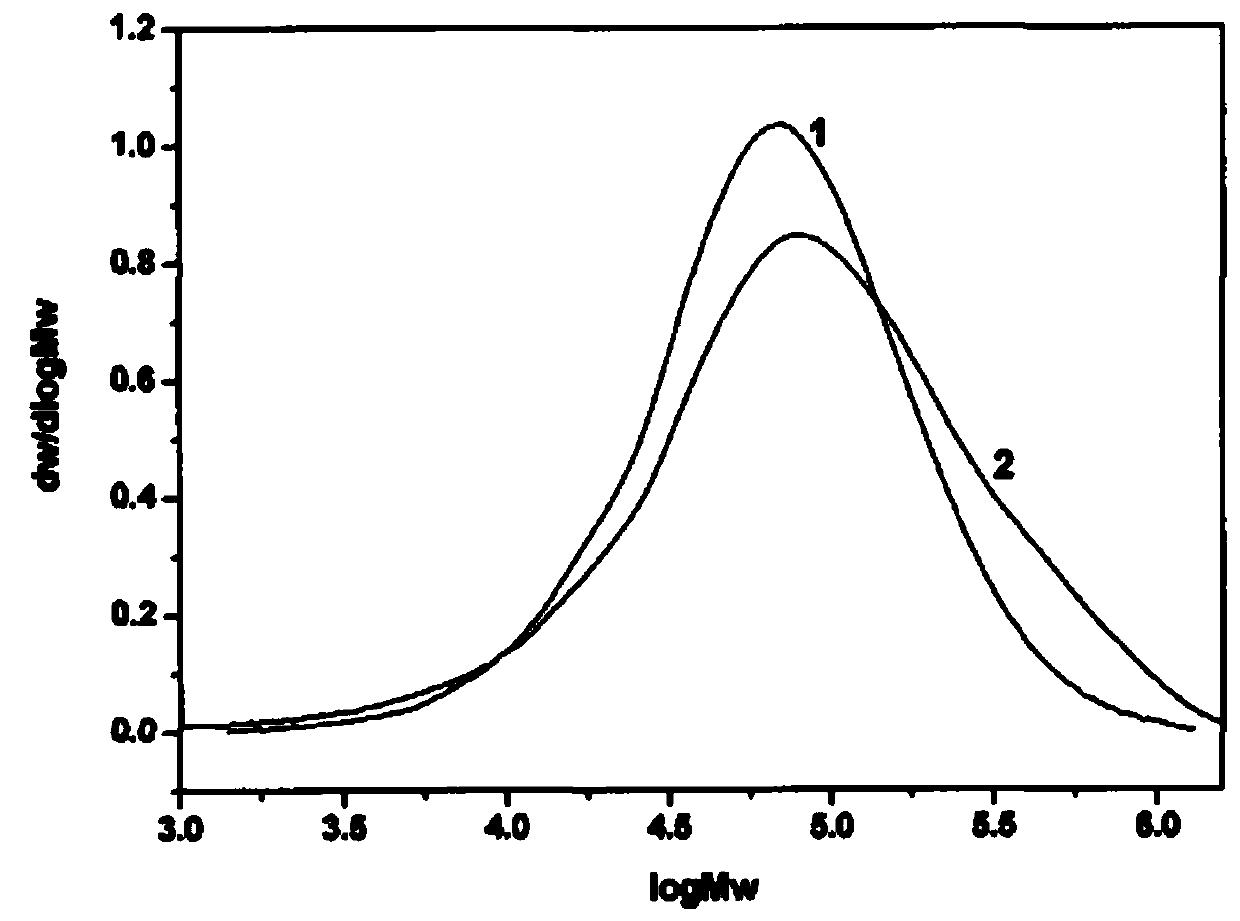

[0046] figure 1 Molecular weight distribution curve for the prepared polyethylene. Among the figure 1 is the polyethylene produced by the existing non-bridging metallocene catalyst; 2 is the MgCl prepared by the present invention 2 / Polyethylene prepared by supporting metallocene catalysts on silica gel carrier. Depend on figure 1 It can be seen that the molecular weight distribution of polyethylene prepared by using the supported ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com