Nickel-based composite anti-slip coating and preparation process thereof

A non-slip coating and preparation technology, applied in metal material coating technology, coating, molten spraying, etc., can solve the problems of easy aging degradation, short corrosion resistance life, poor bonding force, etc., and achieve high bonding strength, Effect of high coefficient of friction and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The surface of the base metal is cleaned, degreased and sandblasted to roughen the surface; the base metal is 6061-T6 aluminum alloy, and its size is 500mm×500mm×20mm. The base metal is cleaned with acetone, the sandblasting pressure is 0.4-0.5MPa, 36 mesh white corundum, and the spacing is 15-20mm.

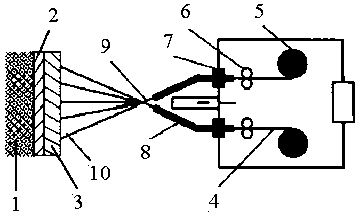

[0018] The supersonic twin-wire arc spraying method is used to prepare a composite anti-slip coating on the surface of the base metal. The NiAl wire 4 on the wire reel 5 passes through the wire feed roller 6 and passes through the conductive block 7, and then converges at the outlet of the air nozzle 8 of the arc spray gun to generate an electric arc 9 , using compressed air to spray the spray particle flow 10 on the surface of the metal 1 at high speed, first forming the bonding layer 2, then spraying the surface layer 3, and finally forming a composite coating that meets the performance. The thickness of the primer layer is 150 μm, and the thickness of the surface layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com