Burning lance and energy-saving and environment-friendly kiln

An energy-saving and environmentally friendly kiln technology, applied in furnaces, burners, combustion methods, etc., can solve the problems of high energy consumption and low utilization rate of waste heat in kilns, achieve full combustion, fast combustion reaction speed, and reduce cross-sectional temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The burner is one of the core components of the kiln, which determines the quality of ceramic products such as brick shape and color. In order to find a spray gun compatible with natural gas, the applicant has always focused on the continuous research and development of the equipment, and developed a new and efficient natural gas energy-saving burner. This embodiment provides a burner, which uses gas as a raw material, and through reasonable control of the gas holes and the combustion-supporting air holes, the combustion is complete and fast, and the energy consumption of the kiln can be reduced.

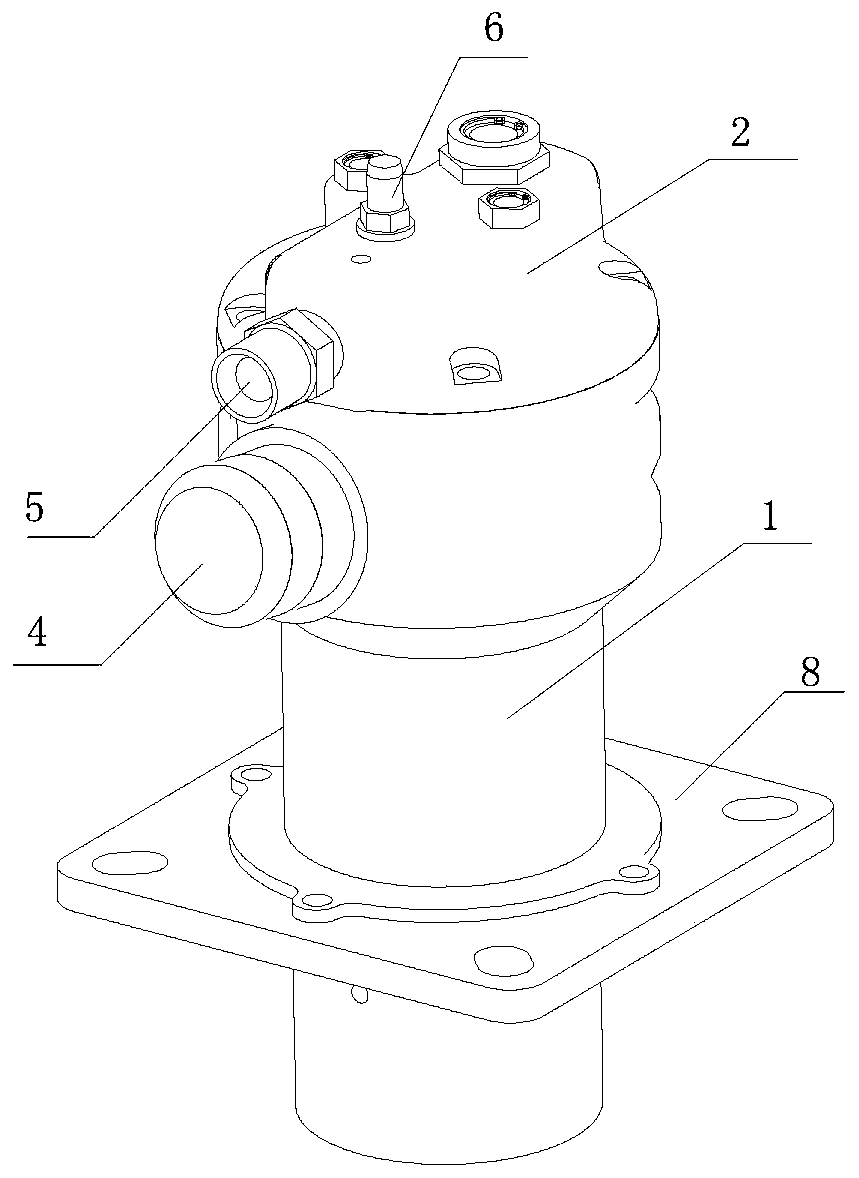

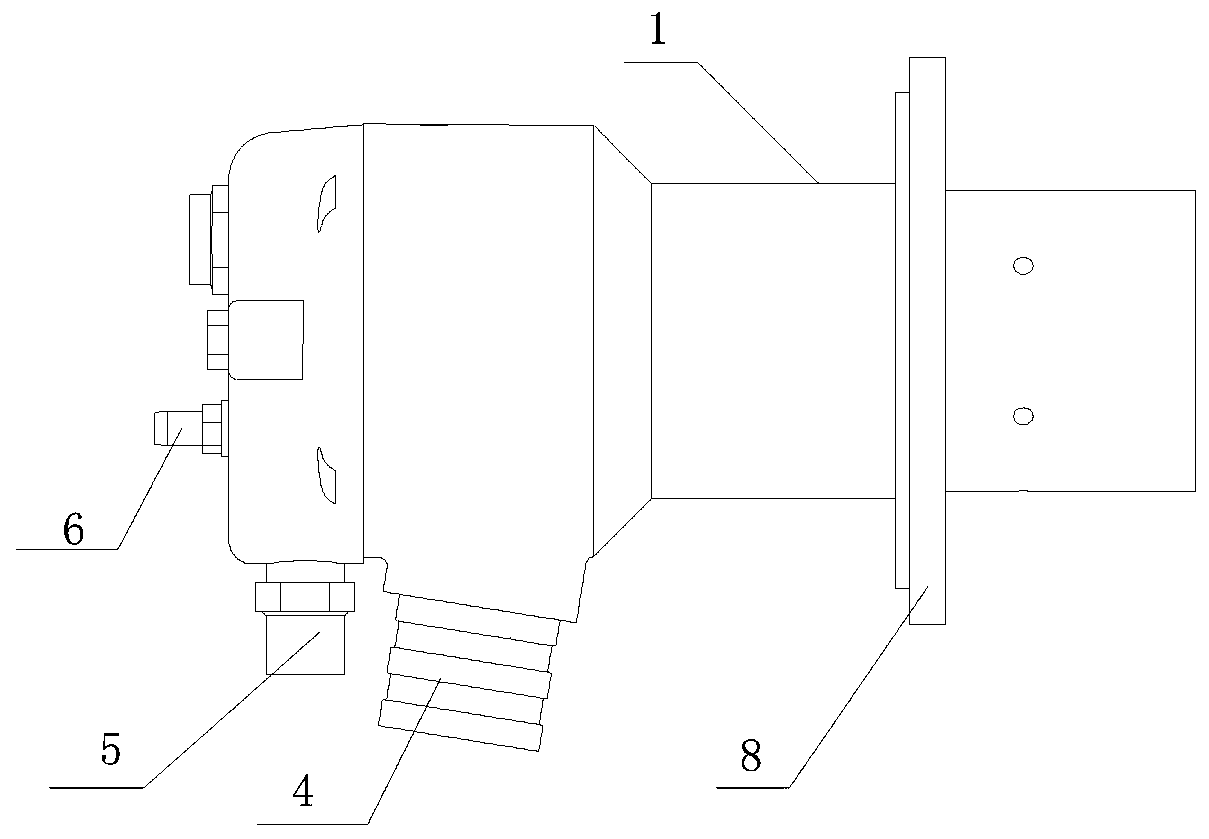

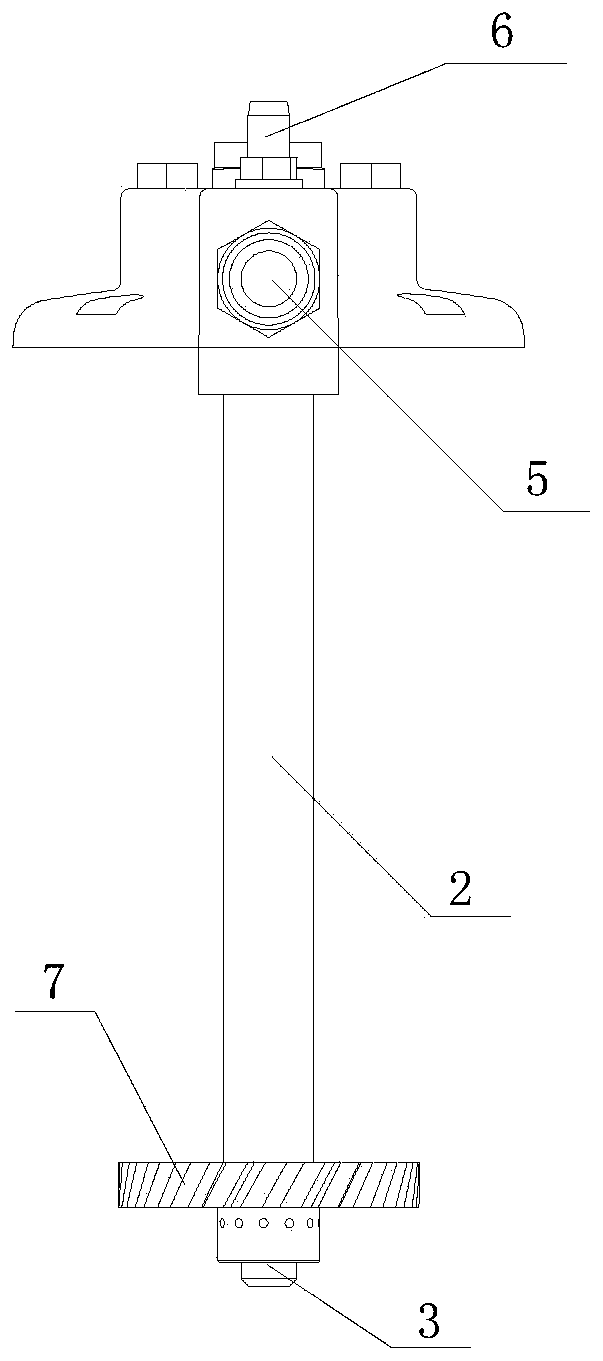

[0030] refer to Figure 1-Figure 4 , the burner includes a holster 1, a gun core 2 and a gun head 3, the holster 1 is fixedly set on the outside of the gun core 2, the holster 1 is provided with a combustion-supporting air inlet 4, the inner wall of the holster 1 and the gun core A combustion air cavity is formed between the outer walls of 2. One end of the gun core 2 is pr...

Embodiment 2

[0034] In order to solve the problems of high energy consumption and low waste heat utilization rate of the kiln in the prior art, this embodiment provides an energy-saving and environment-friendly kiln. Reasonable control of the combustion-supporting air hole, so that the combustion is sufficient and fast, can reduce the energy consumption of the kiln; and the energy-saving and environmentally friendly kiln is equipped with a combustion-supporting air heating heat exchange pipe in the slow cooling section, so that the waste heat of the kiln is obtained. Fully utilized, after the heat exchange pipe is heated by the combustion-supporting air, the heating combustion-supporting air is preheated, reducing the consumption of fuel, thereby achieving the effect of energy saving.

[0035] Specifically, the energy-saving and environmentally friendly kiln includes a kiln body, a burner, a fuel tank, and a combustion fan. The kiln body includes a preheating section, a high temperature sec...

Embodiment 3

[0043] Different from the above-mentioned embodiments, the energy-saving and environment-friendly kiln also includes a heat exchanger, and the top of the slow cooling section is provided with a combustion-supporting air heating heat exchange tube, and the combustion-supporting air heating heat exchange tube is connected to the inlet end of the heat exchanger for heat exchange. The outlet end of the device is connected with the inlet of the combustion-supporting fan through the combustion-supporting pipe. At present, most of the combustion-supporting air used in the kiln is natural air. When the air at normal temperature is sent into the kiln, it will absorb a considerable part of the heat, which often results in waste of heat.

[0044] The combustion-supporting air heating heat exchange tubes in this embodiment are arranged in multiples, and are evenly distributed on the top of the slow cooling section. The diameter of each combustion-supporting air heating heat exchange tube i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com