Composite lithium metal negative pole and preparation method thereof

A metal negative electrode, composite lithium technology, applied in the direction of negative electrode, battery electrode, lithium battery, etc., can solve the problems of inability to expand, complex modification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

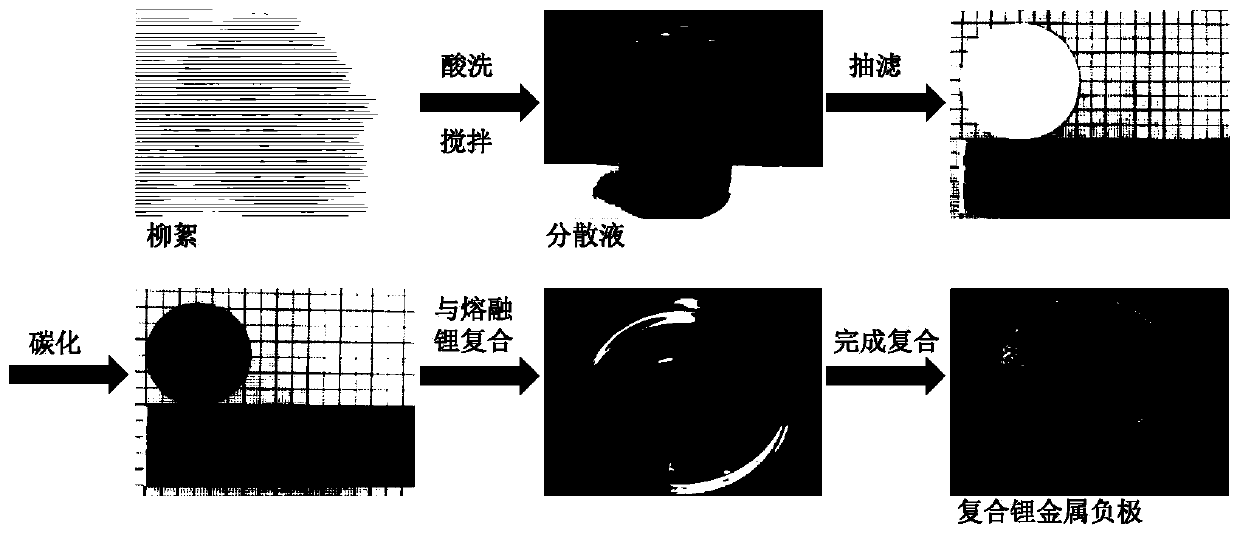

[0027] Example 1: 0.5 g catkins were washed with deionized water, added to 150 ml of 0.5 M nitric acid, and stirred at 300 rpm for 10 h. Catkin flakes were obtained after vacuum filtration, and the flakes were dried in a vacuum oven at 80° C. for 10 h. Put the sheet into a tube furnace, heat up to 800C at 5°C / min in an argon atmosphere, keep it warm for 2h, and cool down to room temperature naturally to obtain a three-dimensional thin carbon sheet. Heat the lithium sheet to 300°C to melt, put in the carbon sheet, wait until the metal lithium is completely impregnated, take it out and cool it down to room temperature naturally to obtain a composite lithium metal negative electrode, in which the metal lithium content is 83%. figure 1 A flow chart showing the preparation of the composite lithium metal negative electrode;

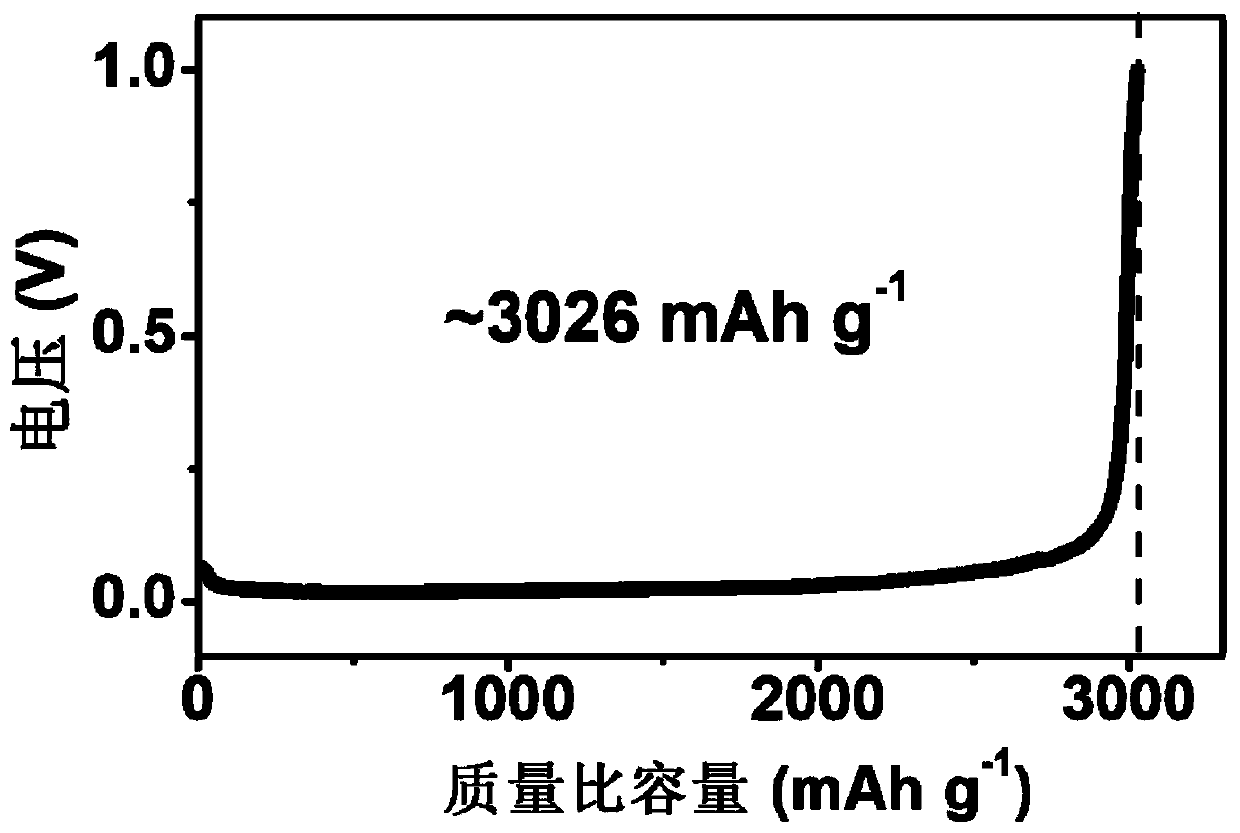

[0028] Assemble the battery with the composite lithium metal negative electrode and the counter electrode lithium sheet, and discharge it to 1V at a current d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com