Slow-release weeding and sterilizing double-effect pesticide and preparation method thereof

A slow-release, pesticide technology, applied to herbicides and algicides, botanical equipment and methods, fungicides, etc., to achieve high application value, strong interaction, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

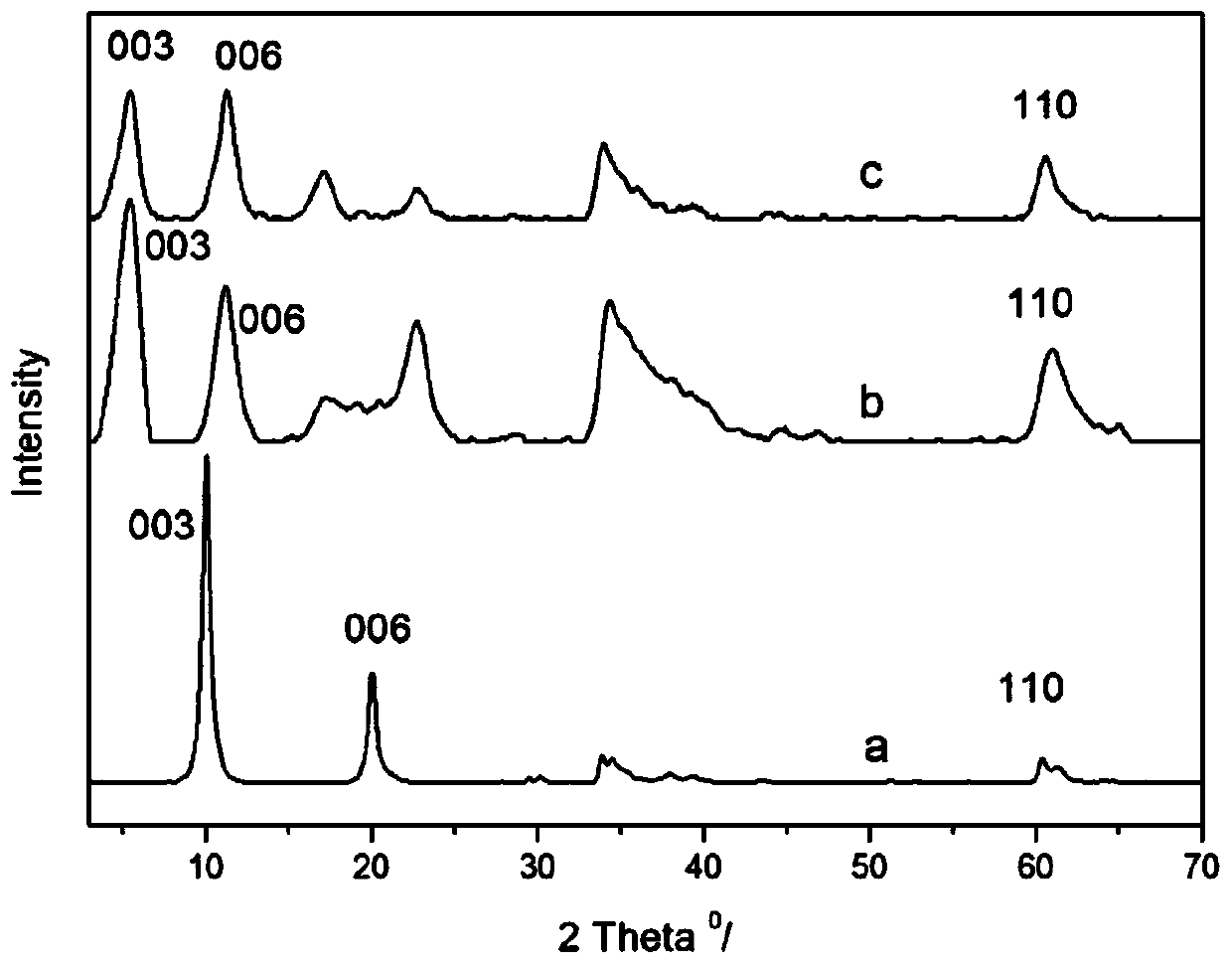

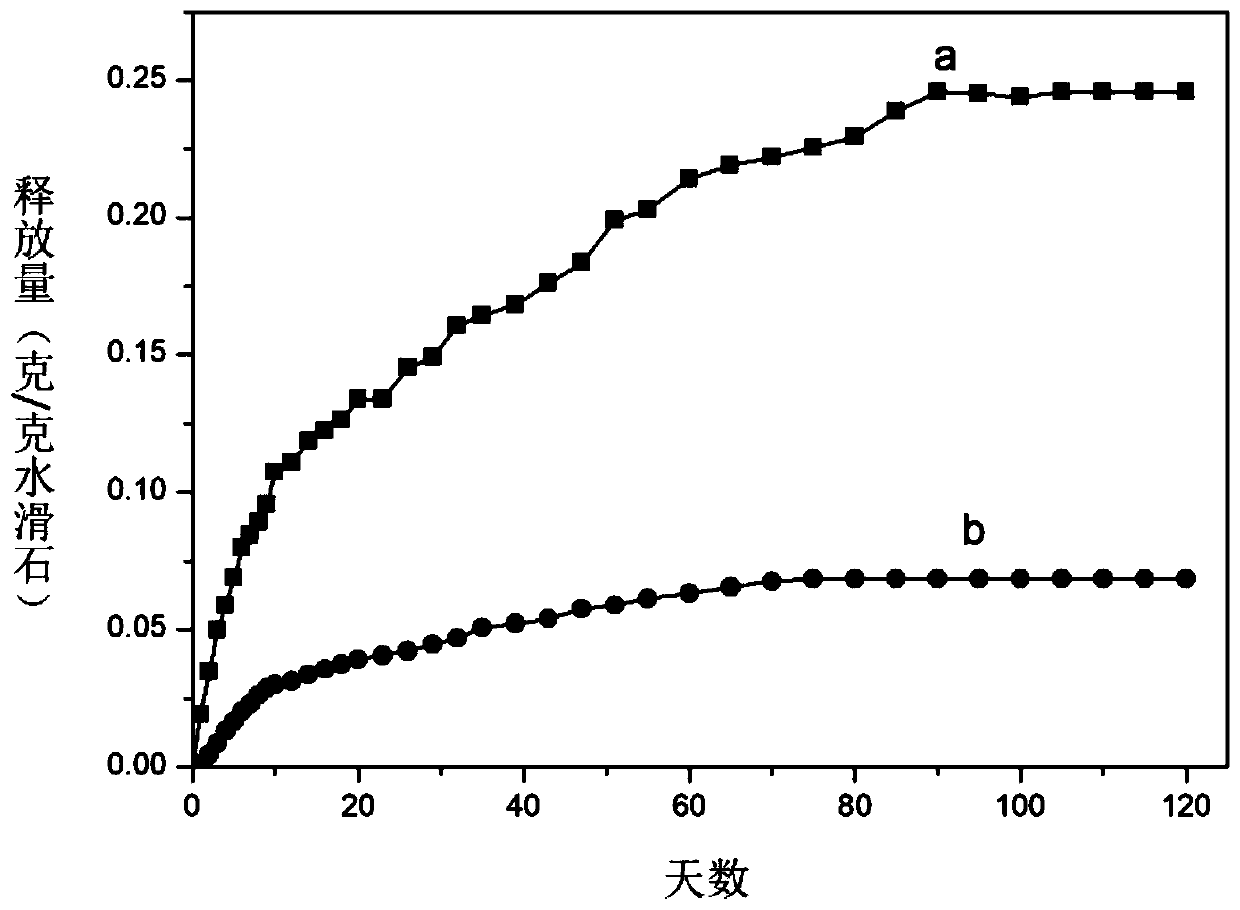

[0039] (1) Weigh 17.8g Zn(NO 3 ) 2 ﹒ 6H 2 O, 11.3g Al(NO 3 ) 3 ﹒ 9H 2 O dissolved in 100ml to remove CO 2 Mixed salt solution was prepared with water, another 5.6g NaOH was dissolved in 50ml to remove CO 2 Prepare alkaline solution in water, N at room temperature 2 Protection Use the double-drop method to add the salt solution and the alkali solution into the four-neck flask, and stir vigorously. Adjust the pH value to 7 with 0.1mol / L NaOH solution. The resulting slurry was crystallized at 60°C for 72 hours, and the product was placed in a centrifuge, centrifuged at a speed of 2500 rpm for 5 minutes, and then used to remove CO 2 Wash with water until neutral; take out the sample and dry it at 50°C for 48 hours for characterization, and obtain the hydrotalcite precursor ZnAl-NO 3 -LDHs, whose Zn 2+ / Al 3+ =2.

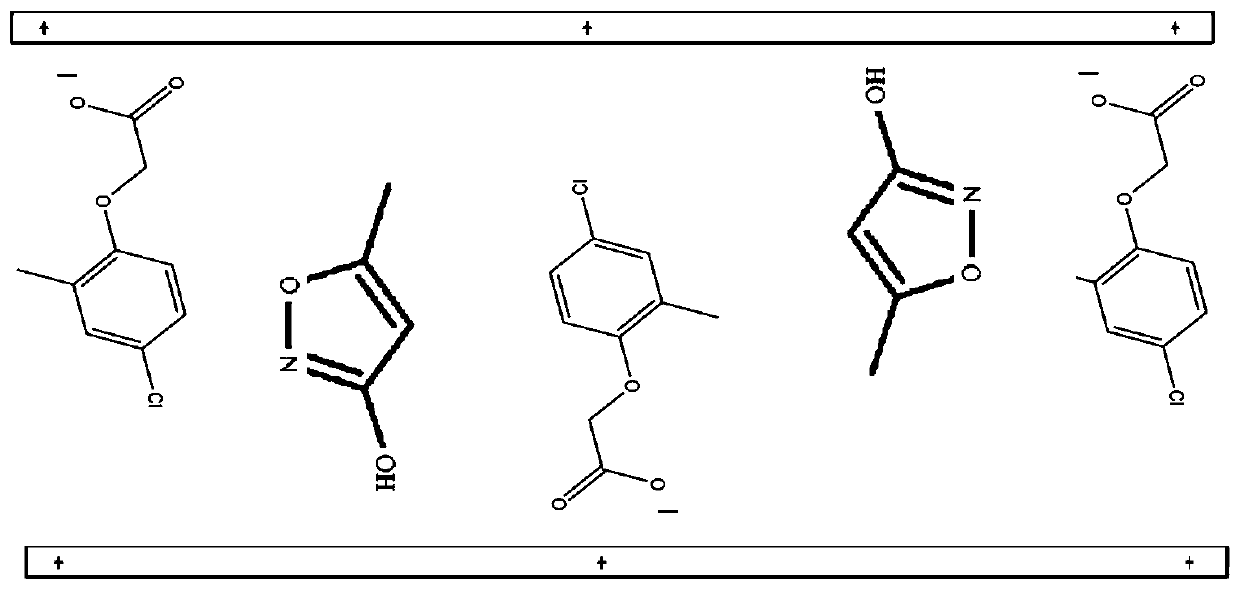

[0040] (2) 8.6g sodium tetrachloride [CH 3 (Cl)C 6 h 3 OCH 2 COONa] solid dissolved in 200mL to remove CO 2 After the deionized water was transferred ...

Embodiment 2

[0045] (1) Weigh 15.4g Mg(NO 3 ) 2 ﹒ 6H 2 O, 11.3g Al(NO 3 ) 3 ﹒ 9H 2 O dissolved in 100ml to remove CO 2 Mixed salt solution was prepared with water, another 2.0g NaOH was dissolved in 50ml to remove CO 2 Prepare alkaline solution in water, N at room temperature 2 The salt solution and the alkali solution were added into the four-necked bottle by the double drop method, and the pH value was adjusted to 10 with 5mol / L NaOH solution after the drop. Centrifuge at rpm for 3 min, then remove CO 2 Wash with water until neutral; take out a small amount of samples and dry them at 90°C for 20 hours for characterization to obtain the hydrotalcite precursor MgAl-NO 3 -LDHs, their Mg 2+ / Al 3+ =2.

[0046] (2) 8.6g sodium tetrachloride [CH 3 (Cl)C 6 h 3 OCH 2 COONa] solid dissolved in 200mL to remove CO 2 After the deionized water was transferred to the four-necked bottle, then add 10g of hydrotalcite precursor MgAl-NO 3 -LDHs,N 2 Protected and heated to 70°C, reacted...

Embodiment 3

[0051] (1) Weigh 17.4g Ni(NO 3 ) 2 ﹒ 6H 2 O, 11.3g Al(NO 3 ) 3 ﹒ 9H 2 O dissolved in 100ml to remove CO 2 Mixed salt solution was prepared with water, another 5.6g NaOH was dissolved in 50ml to remove CO 2 Prepare alkaline solution in water, N at room temperature 2 Protection Use the double-drop method to add the salt solution and the alkali solution into the four-neck flask, and stir vigorously. Adjust the pH value to 7 with 3.0mol / L NaOH solution. The resulting slurry was crystallized at 80°C for 30 h, and the product was placed in a centrifuge, centrifuged at a speed of 3000 rpm for 4 min, and then used to remove CO 2 Wash with water until neutral; take out the sample and dry it at 50°C for 48 hours for characterization, and obtain the hydrotalcite precursor NiAl-NO 3 -LDHs, whose Ni 2+ / Al 3+ =2.

[0052] (2) 8.6g sodium tetrachloride [CH 3 (Cl)C 6 h 3 OCH 2 COONa] solid dissolved in 200mL to remove CO 2 The deionized water was transferred to a four-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com