Welding gun head as well as laser and electric arc composite welding device and method

A laser arc and welding torch head technology, applied in the field of laser arc hybrid welding device and welding torch head, can solve the problems of low welding efficiency and low energy utilization rate of single laser welding, and achieve good welding quality, high photoelectric conversion efficiency, and high reliability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

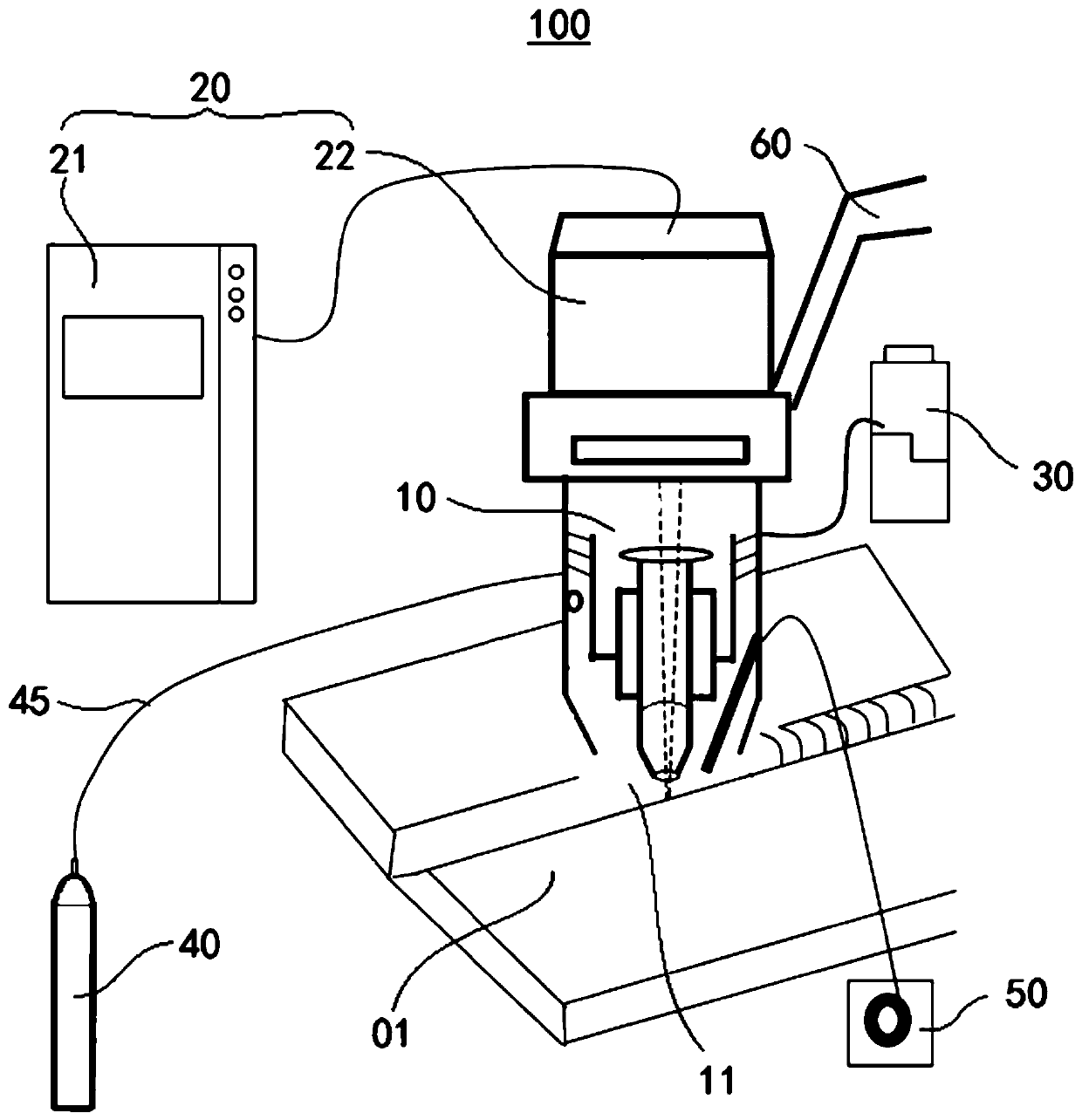

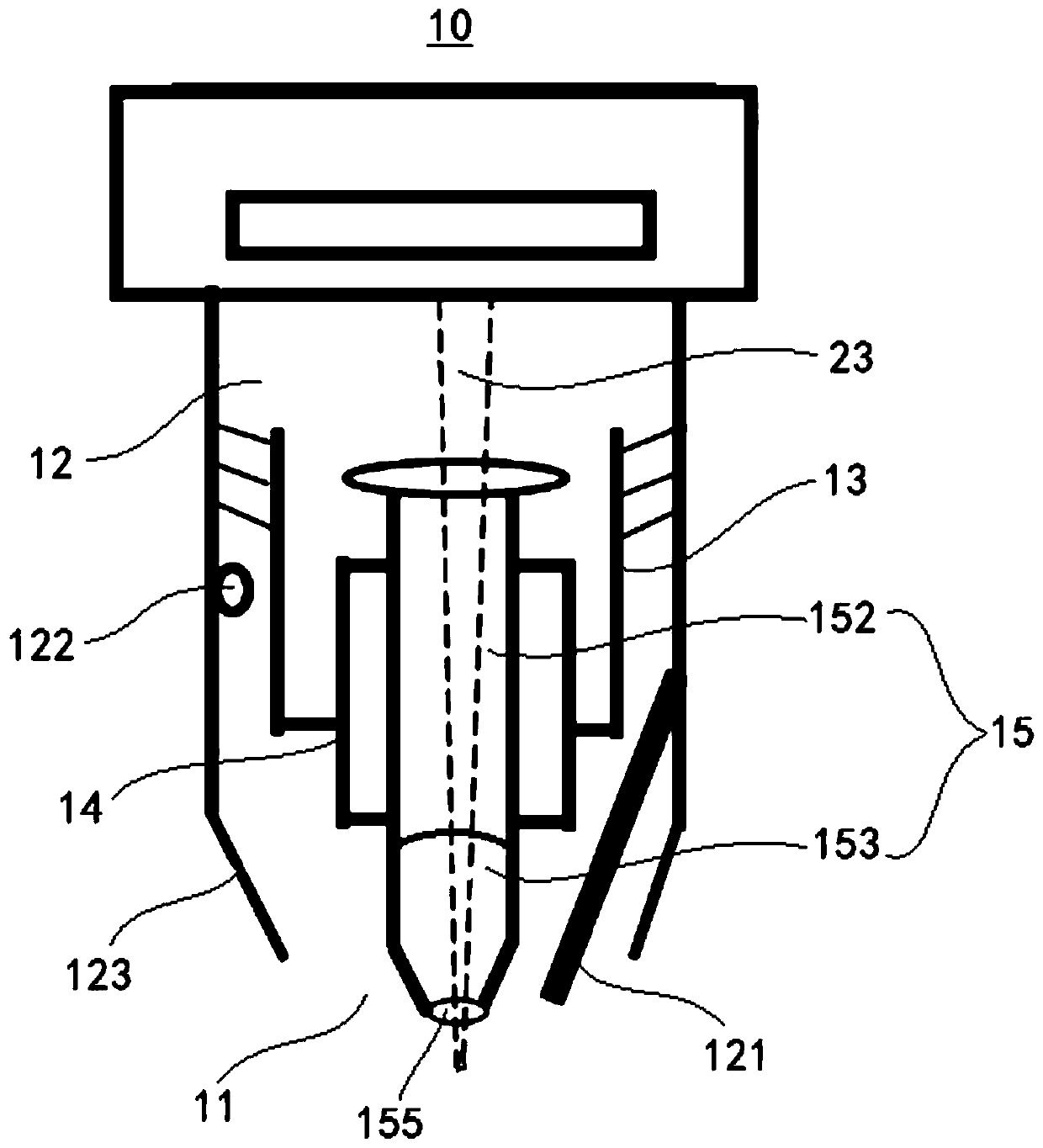

[0036] The embodiment of the present application provides a hybrid laser arc welding device 100, which is used for hybrid welding of the workpiece 01 to be welded, so as to improve welding efficiency and welding quality. The laser arc hybrid welding device 100 includes a welding torch head 10, which is used to combine the pulsed laser and the TIG electric arc, so that the pulsed laser and the TIG electric arc are simultaneously emitted from the nozzle port 11 of the welding torch head 10, and the pulsed laser beam is positioned at the TIG. The center position of the arc.

[0037] Existing laser welding has the characteristics of high heat source energy density and strong penetration ability. However, there are also materials with low laser absorption rate, especially non-ferrous metals such as aluminum alloy, which lead to extremely low energy utilization rate of laser welding; the process equipment of arc welding is simple and the technology is mature. However, there is a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com