Method for treating degradation-resistant industrial wastewater

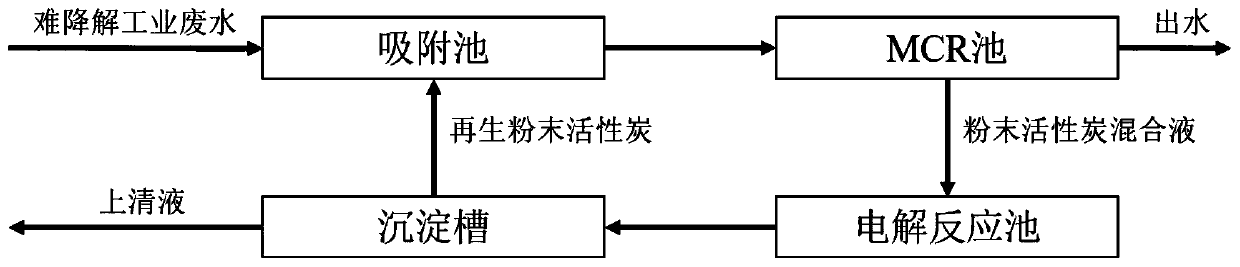

An industrial wastewater, refractory technology, applied in sedimentation treatment, special treatment targets, water/sewage treatment and other directions, can solve the problems of high treatment cost of powder activated carbon, difficult to guarantee regeneration effect, high cost per ton of water treatment, and achieve good application prospects , The effect of economical operation cost and high comprehensive efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Take the MBR effluent of a sewage treatment plant in an industrial park for continuous treatment experiments, the influent flow rate is 1L / h, COD: 200mg / L.

[0082]The waste water enters the adsorption pond, the concentration of powdered activated carbon in the adsorption pond is 1500 mg / L, and the reaction time of the waste water in the adsorption pond is 15 minutes. Detect the COD of the effluent from the adsorption pool: 40mg / L.

[0083] The effluent from the adsorption pool flows into the MCR pool by itself, and is filtered by the built-in submerged hollow membrane module. The COD of the effluent from the MCR pool is further reduced, and the COD: 36mg / L. The residence time of wastewater in the MCR tank is 30min, and the concentration of powdered activated carbon is 5000mg / L. After the wastewater is treated by the MCR pool, the COD reaches the discharge standard.

[0084] In the MCR pool, the mixed solution of powdered activated carbon with an inflow rate of 30% is...

Embodiment 2

[0088] Take the MBR effluent of a sewage treatment plant in an industrial park for continuous treatment experiments, the influent flow rate is 1L / h, COD: 83mg / L.

[0089] The waste water enters the adsorption pond, the concentration of powdered activated carbon in the adsorption pond is 500 mg / L, and the reaction time of the waste water in the adsorption pond is 15 minutes. Detect the COD of the effluent from the adsorption pool: 25mg / L.

[0090] The effluent from the adsorption pool flows into the MCR pool by itself, and is filtered by the built-in submerged hollow membrane module. The COD of the effluent from the MCR pool is further reduced, and the COD: 23mg / L. The residence time of wastewater in the MCR tank is 30min, and the concentration of powdered activated carbon is 4000mg / L. After the wastewater is treated by the MCR tank, the COD reaches the Class IV water standard of the surface water environmental quality standard (CB3838-2002).

[0091] In the MCR pool, the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com