A kind of preparation method and application of oil-absorbing hydrogel

A hydrogel and oil-based technology, applied in gel preparation, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low adsorption efficiency and weak adsorption effect, and achieve easy operation, good adsorption capacity, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the oil-absorbing hydrogel of the present invention comprises the following steps:

[0026] (1) chitosan is dissolved in the acetic acid solution whose concentration is 2wt%;

[0027] (2) polyvinyl alcohol is completely dissolved in water;

[0028] (3) mixing the two solutions according to the mass ratio of chitosan and polyvinyl alcohol in a ratio of 1:1 to 1:10, and stirring to make them evenly mixed;

[0029] (4) According to the mass ratio of chitosan and crosslinking agent, genipin was added in a ratio of 1:0.03 to 1:0.50, and at room temperature, stirring was continued, and a transparent hydrogel appeared after 8 hours, and continued Stir until stirring is difficult, stop the reaction, and obtain a hydrogel.

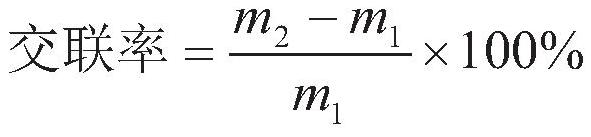

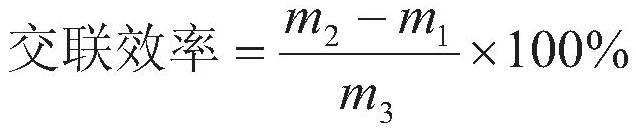

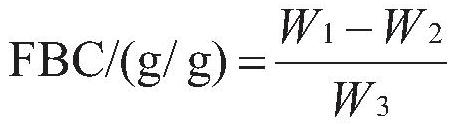

[0030] (5) In order to determine the characteristic parameters of the copolymer hydrogel, the required treatment process is as follows: filter out the liquid, first wash with acetic acid solution with a concentration of 2wt%, then...

Embodiment 1

[0043]1 g of chitosan with a degree of deacetylation of 90% and a molecular weight of 800,000 was dissolved in 100 mL of an acetic acid solution with a concentration of 2 wt%. Add 2 g of polyvinyl alcohol to the water, stir to make it fully dissolved, and the viscosity value of the polyvinyl alcohol used is 6.3. Mix the two solutions evenly, then add genipin into the mixture to make the concentration of genipin 0.5wt%, stir the reaction at room temperature, and a transparent gel will appear after 8 hours, until the gel More and more, stirring is difficult, and the reaction stops.

[0044] The liquid was filtered off, first washed with acetic acid solution with a concentration of 2wt%, then washed with deionized water until neutral, removed unreacted chitosan, polyvinyl alcohol, and cross-linking agent, took out the hydrogel, filtered off Moisture, vacuum-dried at 80° C. to constant weight to obtain a dry gel, the cross-linking rate was 96%, the cross-linking efficiency was 35...

Embodiment 2

[0046] 1 g of chitosan with a degree of deacetylation of 95% and a molecular weight of 400,000 was dissolved in 100 mL of an acetic acid solution with a concentration of 2 wt%. Add 3 g of polyvinyl alcohol to the water, stir to make it fully dissolved, and the viscosity value of the polyvinyl alcohol used is 6.3. Mix the two solutions evenly, then add genipin into the mixture to make the concentration of genipin 1 wt%, stir the reaction at room temperature, and a transparent gel will appear after 8 hours, until the gel becomes more and more The more, the more difficult it is to stir, and the reaction stops.

[0047] The liquid was filtered off, first washed with acetic acid solution with a concentration of 2wt%, then washed with deionized water until neutral, removed unreacted chitosan, polyvinyl alcohol, and cross-linking agent, took out the hydrogel, filtered off Moisture, vacuum-dried at 80° C. to constant weight to obtain a dry gel, the cross-linking rate was 112%, the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com