Polyasparagine derivative modified oil-water separation stainless steel mesh film and preparation method thereof

A polyasparagine, oil-water separation technology, applied in separation methods, liquid separation, grease/oily substances/suspton removal devices, etc., can solve the problems of limiting the large-scale application of dopamine, secondary pollution of waste environment, waste of dopamine, etc. , to achieve the effect of maintaining water resistance, high safety, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

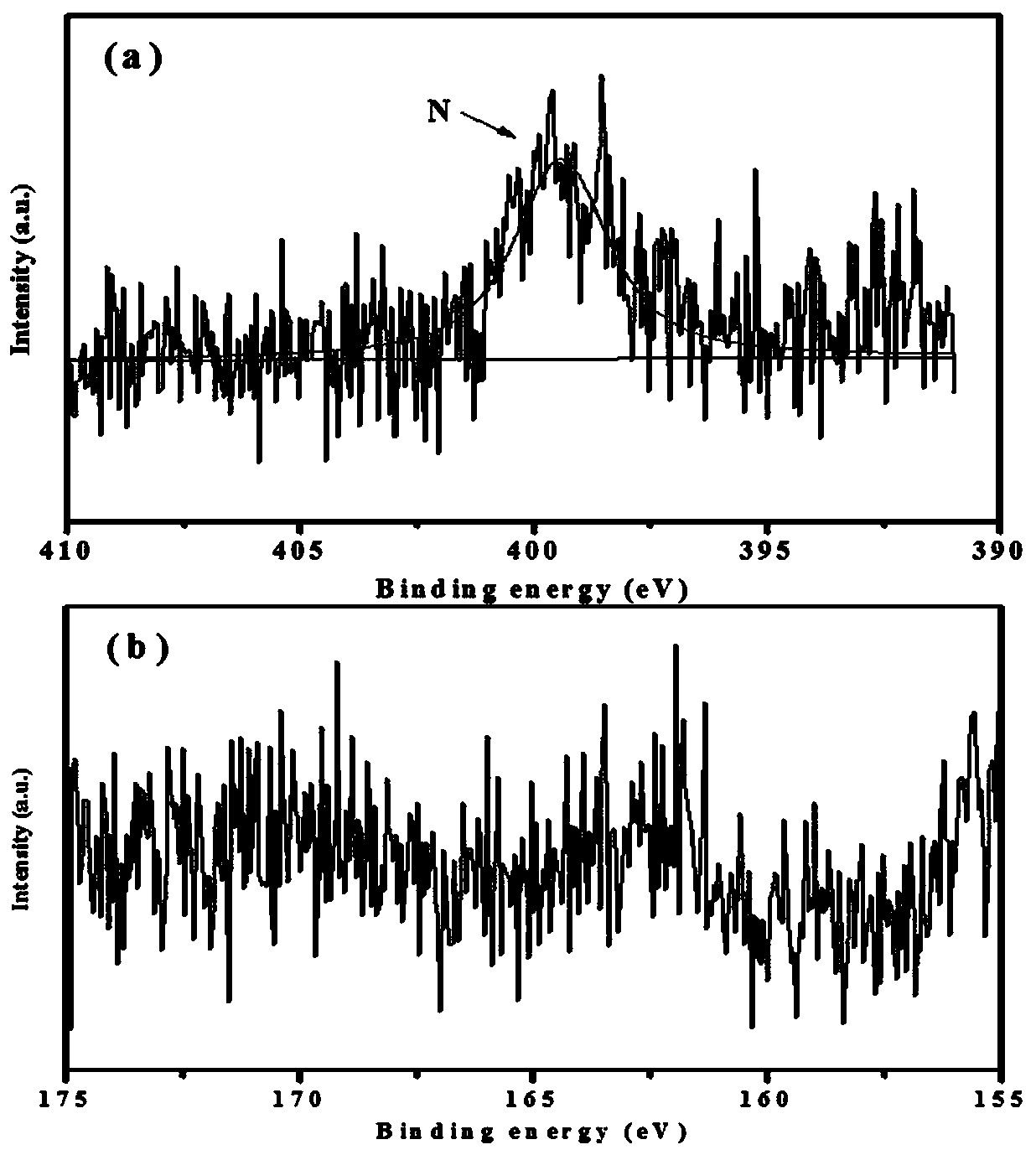

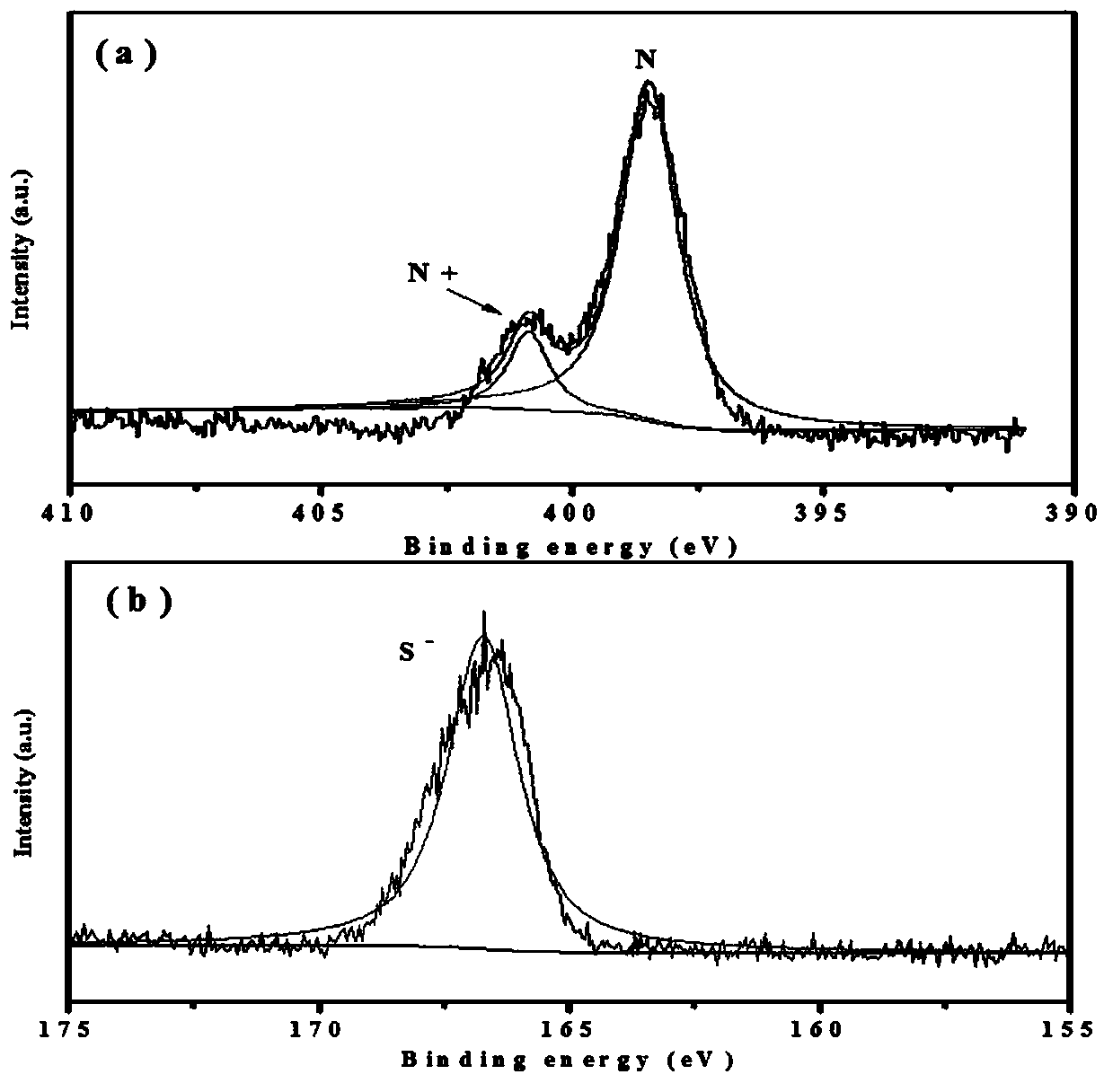

[0043] (1) Preparation of dopa / zwitterion functionalized polyasparagine derivatives

[0044] Dissolve 100g of polysuccinimide PSI (molecular weight 7000) in 300g of DMSO; add 39.1g of dopamine hydrochloride and 100ml of triethylamine. After the dissolution is complete, carry out ring-opening reaction at 60°C for 8 hours; then, add 21.1g of N,N-Dimethyl-1,3-propanediamine, conduct ring-opening reaction at 60°C for 12h; then, add 38.21g of dodecylamine, perform ring-opening reaction at 60°C for 12h; then, add 3.14g of ethanolamine , ring-opening reaction at 60°C for 24h; finally, add 30.18g of 1,3-propane sultone, react at 40°C for 24h, the side group tertiary amine group grafted to the polyasparagine derivative Perform quaternization reaction; prepare dopa / zwitterion functionalized polyasparagine derivatives after purification and drying;

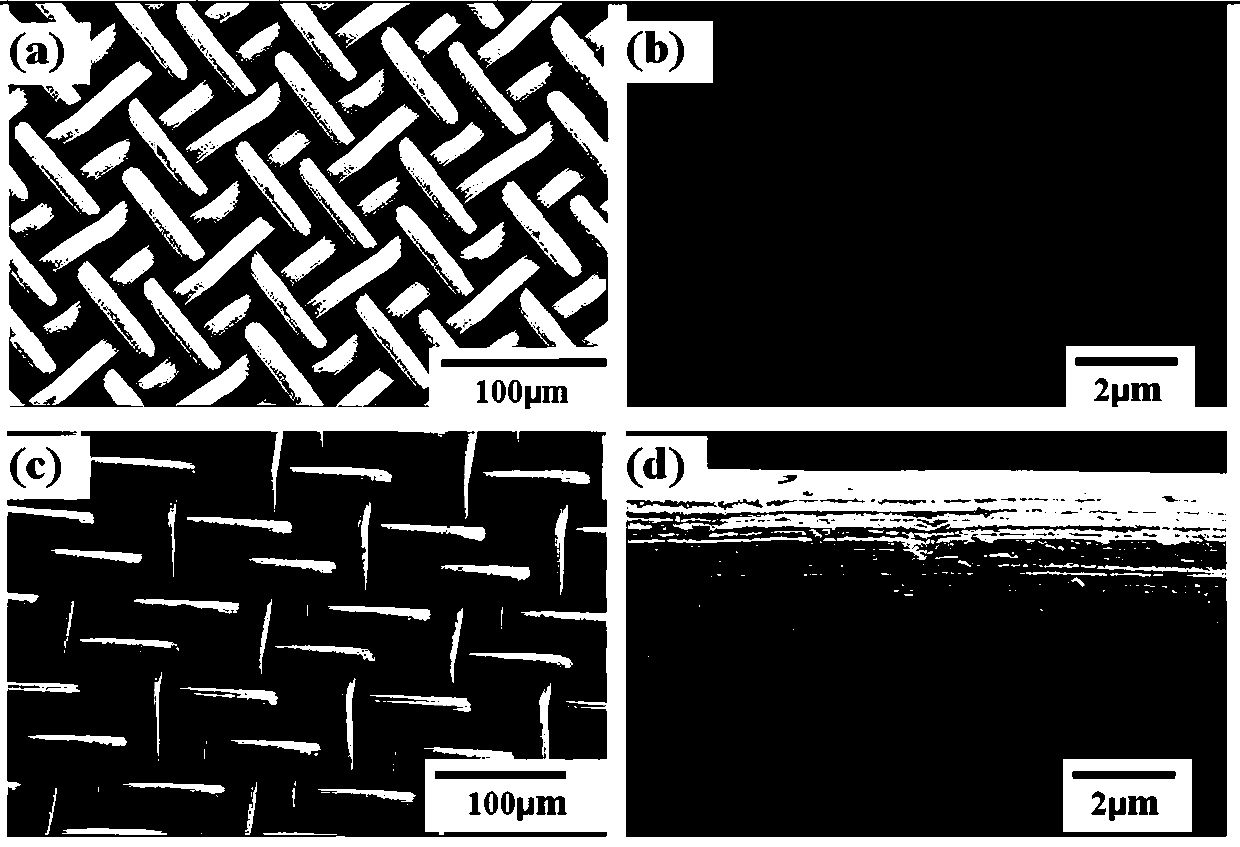

[0045] (2) Preparation of oil-water separation stainless steel mesh

[0046] Mix 10g of dopa / zwitterionic functionalized polyasparagine d...

Embodiment 2

[0066] (1) Preparation of dopa / zwitterion functionalized polyasparagine derivatives

[0067] Dissolve 100g of polysuccinimide PSI (molecular weight: 15,000) in 500g of DMF; add 39.1g of dopamine hydrochloride and 100ml of triethylamine, and after the dissolution is complete, carry out ring-opening reaction at 70°C for 3 hours; then, add 31.6g of N,N-Dimethyl-1,3-propanediamine, conduct ring-opening reaction at 60°C for 7h; then, add 19.11g of dodecylamine, perform ring-opening reaction at 80°C for 2h; then, add 12.6g of ethanolamine , ring-opening reaction was carried out at 30°C for 24h; finally, 45.3g of 1,3-propane sultone was added and reacted at 50°C for 5h. Perform quaternization reaction; prepare dopa / zwitterion functionalized polyasparagine derivatives after purification and drying;

[0068] (2) Preparation of oil-water separation stainless steel mesh

[0069] Mix 10g dopa / zwitterionic functionalized polyasparagine derivatives, 1g sodium percarbonate and 1000g water,...

Embodiment 3

[0072] (1) Preparation of dopa / zwitterion functionalized polyasparagine derivatives

[0073] Dissolve 100g of polysuccinimide PSI (molecular weight: 100,000) in 100g of ethyl acetate; add 58.7g of dopamine hydrochloride and 180ml of triethylamine. After the dissolution is complete, carry out ring-opening reaction at 60°C for 8 hours; then, add 42.1 g of N,N-dimethyl-1,3-propanediamine, conduct ring-opening reaction at 60°C for 8h; then, add 49.7g of hexadecylamine, perform ring-opening reaction at 60°C for 8h; then, add 3.15g The ethanolamine was subjected to a ring-opening reaction at 40°C for 24h; finally, 67.3g of 1,4-butane sultone was added and reacted at 40°C for 26h. The group undergoes quaternization reaction; after purification and drying, dopa / zwitterion functionalized polyasparagine derivatives are produced;

[0074] (2) Preparation of oil-water separation stainless steel mesh

[0075] Mix 100g of dopa / zwitterionic functionalized polyasparagine derivatives, 8g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com