Naked-eye 3D mobile phone backboard film and preparation method thereof as well as mobile phone

A backplane film, 3D technology, applied in sub-office equipment, telephone structure, optics, etc., can solve the problems of difficult process control, heavy pollution, and inability to realize microscopic texture patterns, etc., to increase surface free energy and surface tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

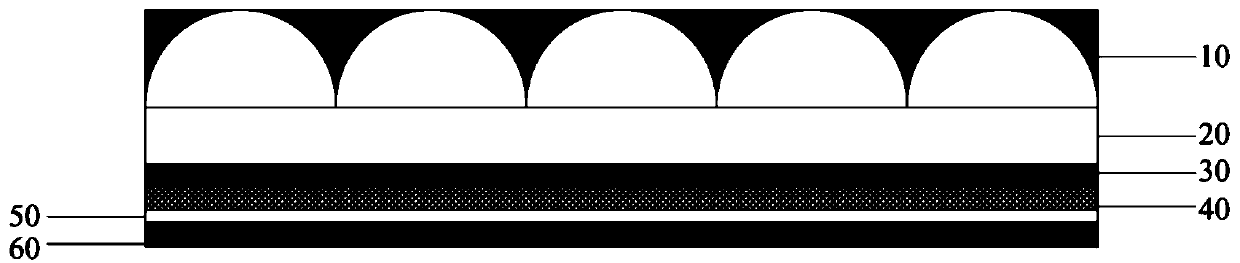

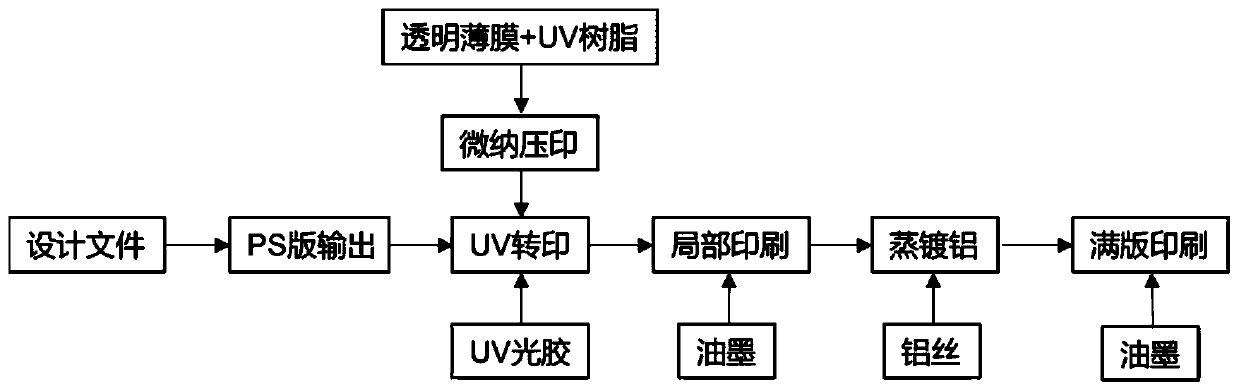

[0105] The overall preparation process flow chart of the naked-eye 3D mobile phone backplane film is as follows figure 2 Shown, its specific preparation method is as follows:

[0106] Select a transparent film with high surface smoothness, strong adhesion to the UV resin composition, 90% to 92% transmittance in the visible light band, polyethylene terephthalate material, and a thickness of 80 μm, and double-coat it. Surface chemical treatment, the treatment method can be selected from the surface chemical treatment methods commonly used in this field, such as anodic oxidation, surface super hardening, salt bath compounding, chemical oxidation, chemical vapor deposition.

[0107] micro-nanoimprint

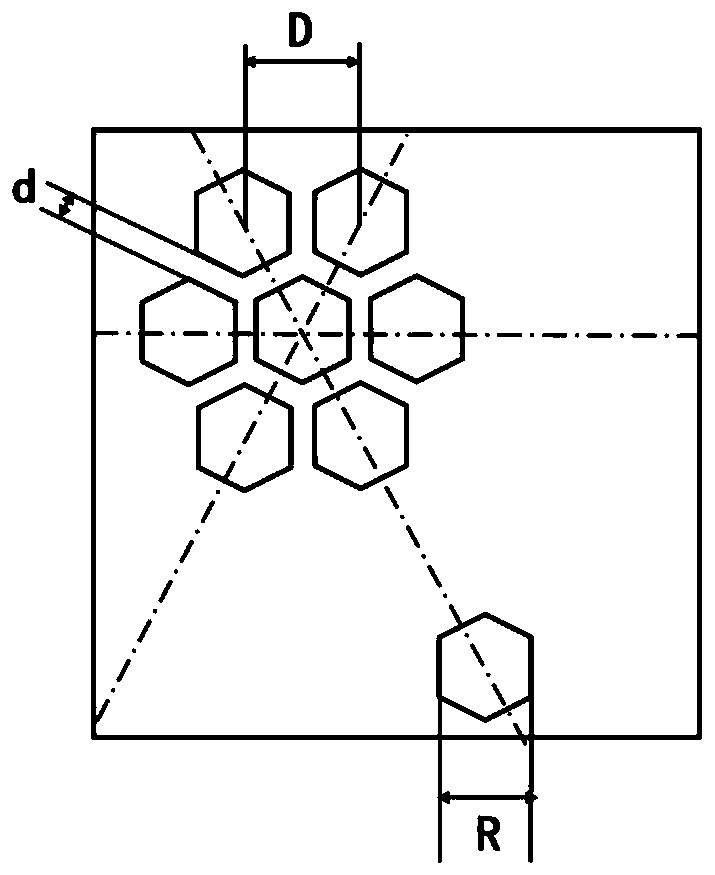

[0108] Using the transparent film that has been chemically treated on both sides as the substrate, the UV resin composition is embossed on the front of the transparent film by micro-nano imprinting to form a microlens array layer. The optical mold of the microlens array is a ni...

Embodiment 2

[0125] The implementation of this embodiment is roughly the same as in Example 1, the difference being that the UV transfer printing method is specifically:

[0126] The PS plate is transferred into a sub-mold, sub-mold + UV photoresist + microlens film material (transparent film embossed with a microlens array layer), and a microstructure pattern is prepared on the back of the transparent film. Through the rotor mold, the PS plate indirectly The microstructure pattern is transferred to the microlens film material; wherein, the base material of the sub-mold is polycarbonate.

experiment example 1

[0127] Experimental example 1 Visual effect and wear resistance of naked-eye 3D mobile phone backplane film

[0128] Visual effects

[0129] Such as Figure 5 As shown, by adjusting parameters such as the size and spacing of the basic elements of the 3D micro-text, a multi-channel and multi-color 3D display effect can be presented.

[0130] Such as Image 6 As shown, by adjusting parameters such as the size and spacing of the basic elements of 3D micro-graphics, 3D display effects such as floating, sinking, zooming in, zooming out, gradients, rules, irregular shapes, and different depths of field can be presented.

[0131] Such as Figure 7 As shown, by performing deformation processing such as sphericalization, shrinkage, diffusion, and polarization on different areas of the same design file, and slightly changing the arrangement spacing and position of the basic elements of the 3D micro-text, a more personalized design can be achieved. 3D display effect.

[0132] We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com