Fiber laser-based large mode field photonic crystal fiber

A technology of photonic crystal fiber and fiber laser, which is applied in the direction of cladding fiber, optical waveguide, light guide, etc., can solve the problems of difficult fiber performance and achieve high beam quality, large mode field area, and low nonlinear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

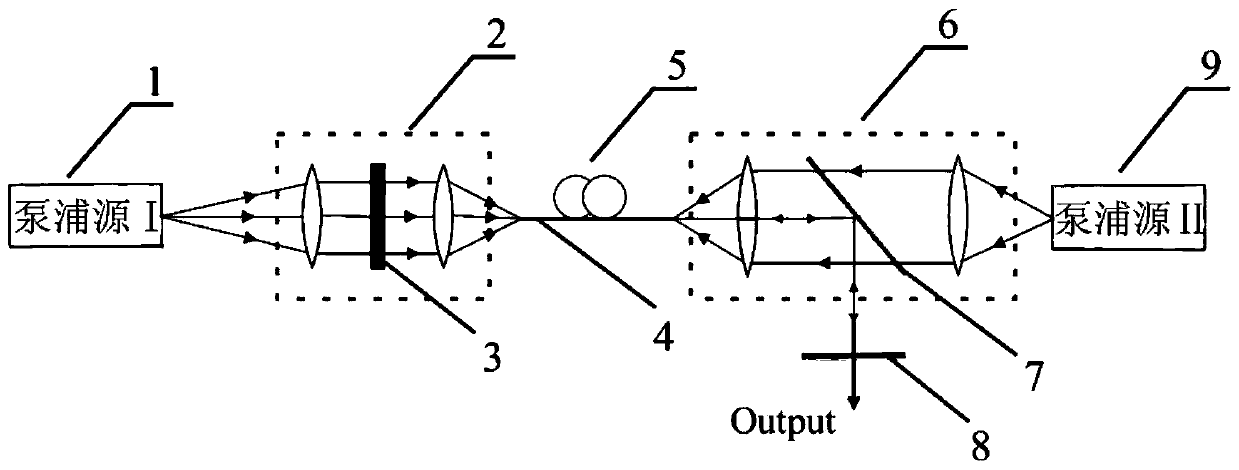

[0045] The present invention will be further described below in conjunction with accompanying drawing:

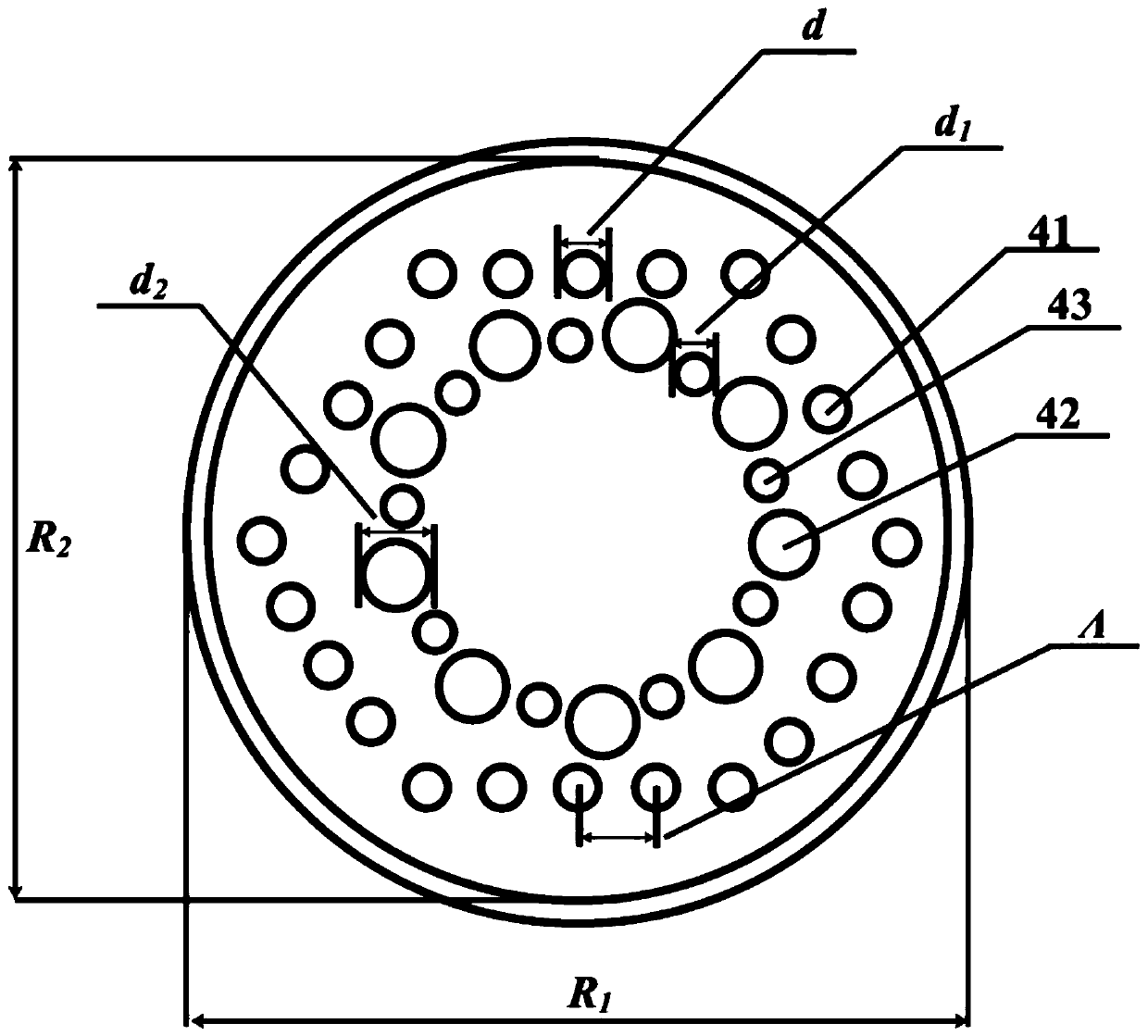

[0046] Such as figure 2 as shown,

[0047] A large mode field photonic crystal fiber 4 based on a fiber laser, including a perfect matching layer, a core layer and a cladding layer, the cladding layer is placed outside the fiber core layer, and the perfect matching layer is placed outside the cladding layer; the cladding layer includes a regular hexagonal period A plurality of air holes I41 with a diameter d in a permanent arrangement;

[0048] The core layer includes nine regular nonagonal periodic arrays whose diameters are all d 2 The air hole II 42, nine diameters are d 1 The air hole III 43;

[0049] Air holes II42 and air holes III43 are distributed at intervals;

[0050] Nine air holes II 42 are respectively placed at nine endpoints of the regular nonagon;

[0051] Nine air holes III 43 are placed at the midpoints of the nine sides of the regular nonagon respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com