Full liquid phase organ chip and preparation method thereof

An organ chip and liquid phase technology, applied in the field of biochip and its preparation, can solve the problems of complex system, inability to simulate dynamic changes of human tissue, difficulty in changing structure, etc., and achieve universality, convenient and fast detection, and mild preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

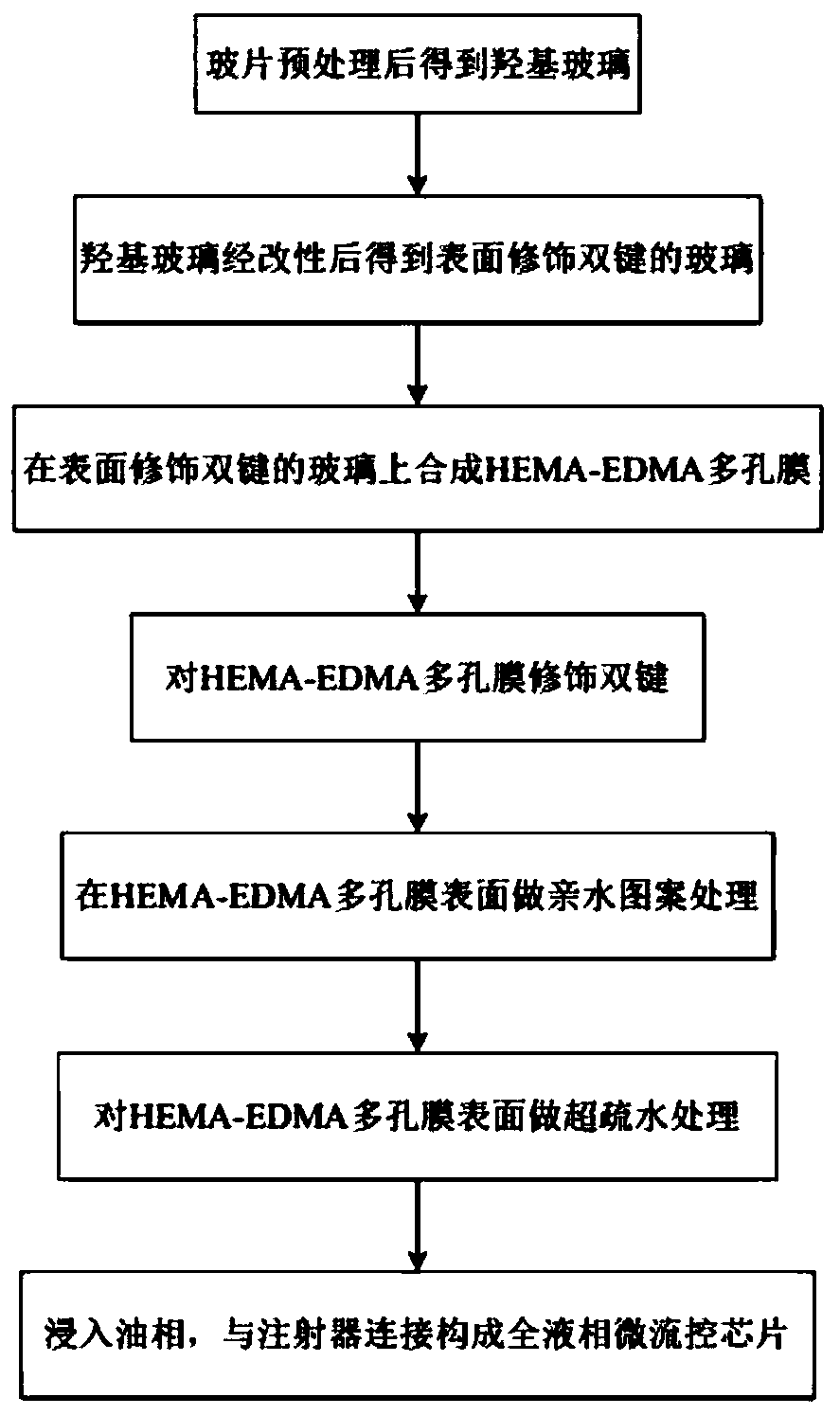

[0034] In this example, the process of preparing the all-liquid-phase organ chip is as follows: figure 1 As shown, it specifically includes the following steps:

[0035] (1) Preparation of surface-modified double bond glass

[0036] Add 30 μL of 3-(methacryloyloxy)propyltrimethoxysilane solution to the overlapped gap between the two pretreated hydroxy glasses, so that the solution completely infiltrates the surface between the overlapped glass slides while ensuring that no bubbles are generated, and react for 1 hour , washed with water and ethanol for several times, and dried to obtain a glass slide with surface-modified double bonds;

[0037] The mass concentration of 3-(methacryloyloxy)propyltrimethoxysilane in the 3-(methacryloyloxy)propyltrimethoxysilane solution is 20 wt%, and the solvent is ethanol.

[0038] (2) Preparation of polymer layer porous membrane

[0039] Prepare the prepolymer mixture: the prepolymer mixture solution includes the following components by vol...

Embodiment 2

[0051] (1) Preparation of substrates with surface-modified double bonds

[0052] This step is basically the same as in Example 1, except that the mass concentration of 3-(methacryloyloxy)propyltrimethoxysilane in the 3-(methacryloyloxy)propyltrimethoxysilane solution is 10 wt%. The solvent is ethanol.

[0053] Wherein, the substrate is plastic, and the plastic substrate is pretreated with oxygen plasma to make it hydrophilic, and then the same steps as in Example 1 are used to modify the substrate.

[0054] (2) Preparation of polymer layer porous membrane

[0055] This step prepares polymer layer porous film and embodiment 1 is substantially the same, and difference is: wherein prepolymer mixture solution comprises 15vol% HEMA (monomer), 6vol% EDMA (crosslinking agent), 50vol% cyclohexanol ( Porogen), 29vol% n-decyl alcohol (porogen), and benzoin dimethyl ether (DMPA) as photoinitiator, the addition of photoinitiator accounted for the concentration of the mixture is 0.5mg / mL...

Embodiment 3

[0065] (1) Preparation of surface-modified double bond glass

[0066] This step is basically the same as Example 1, except that the mass concentration of 3-(methacryloyloxy)propyltrimethoxysilane in the 3-(methacryloyloxy)propyltrimethoxysilane solution is 25 wt%. The solvent is ethanol.

[0067] (2) Preparation of polymer layer porous membrane

[0068] This step prepares polymer layer porous membrane and embodiment 1 is substantially the same, and difference is: wherein prepolymer mixture solution comprises 16vol% HEMA (monomer), 4vol% EDMA (crosslinking agent), 40vol% cyclohexanol ( Porogen), 40vol% n-decyl alcohol (porogen), and with benzoin dimethyl ether (DMPA) as photoinitiator, the addition of photoinitiator accounted for the concentration of the mixture is 4mg / mL;

[0069] (3) Preparation of porous membrane with hydrophobic polymer layer

[0070] In a fume hood environment, respectively add 40 mL of dichloromethane (DCM), 80 μL of 4-pentynoic acid and 100 μL of N, N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com