Preparation method and application of light-emitting diode of ligand-stripped quantum dot light-emitting layer

A quantum dot light-emitting and light-emitting diode technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of low current density of quantum dot light-emitting diode devices and affect the brightness of quantum dot light-emitting diode devices, and achieve High-efficiency lighting sources and display devices, low production costs, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

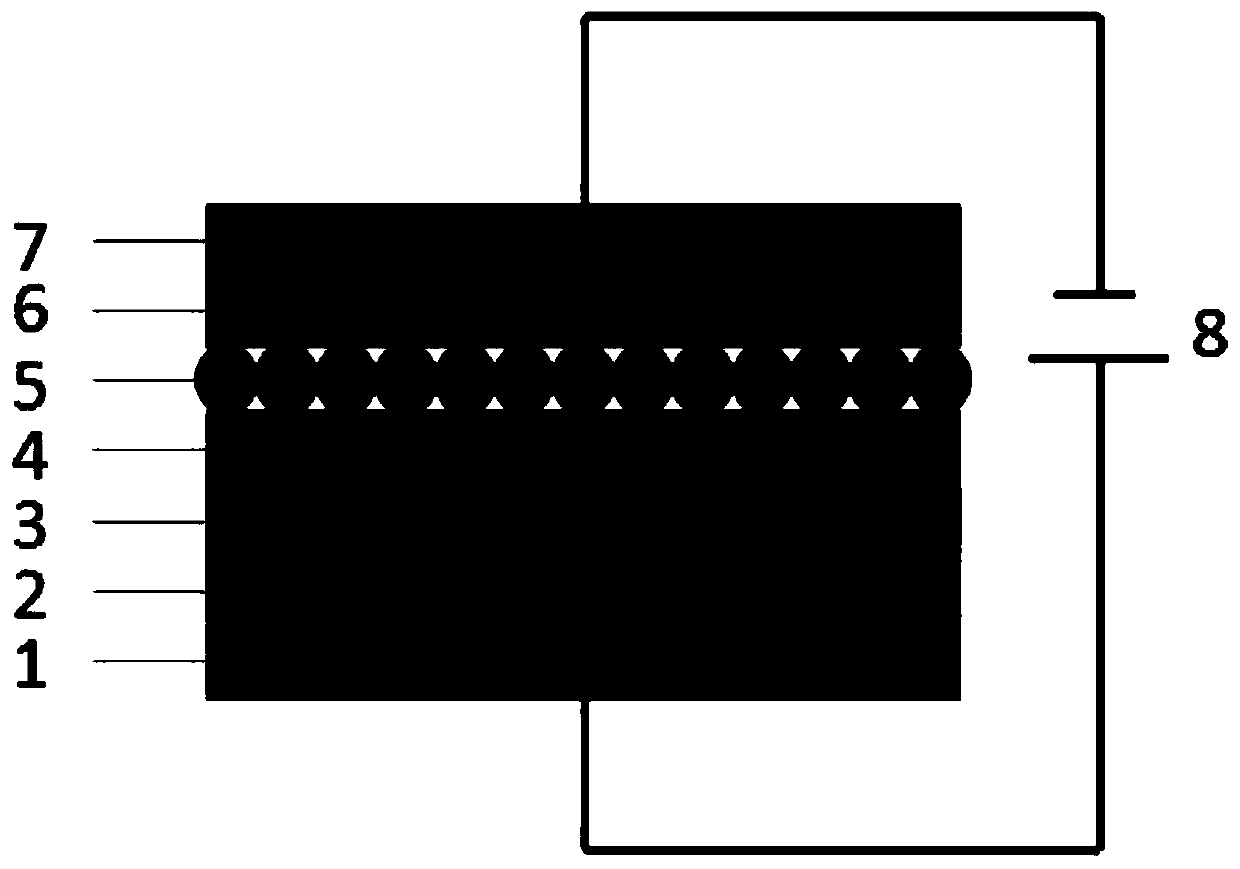

Image

Examples

Embodiment 1

[0027] A method for preparing a light-emitting diode with a ligand-stripped quantum dot light-emitting layer, the method comprising the following steps,

[0028] Step 1: Quantum dot solution preparation: Quantum dots are dissolved in dichloroethane to prepare a quantum dot solution with a concentration of 20 mg / m; wherein, quantum dots are colloidal nano-semiconductors composed of III-VI or II-V elements Material.

[0029] Step 2: Quantum dot ligand stripping: take 10ml of the quantum dot solution in step 1, add 1ml of electrophile, the electrophile can be benzoyl chloride, and sonicate for 10min;

[0030] Step 3: Quantum dot redispersion: add 0.5ml N,N-dimethylformamide to the solution in step 2, purify twice, and prepare quantum dot N,N-dimethylformamide with a concentration of 20mg / ml solution;

[0031] Step 4: Preparation of ligand-stripped quantum dot luminescent layer: spin-coat quantum dot N,N-dimethylformamide solution in step 3 on the hole transport layer, and annea...

Embodiment 2

[0040] A method for preparing a light-emitting diode with a ligand-stripped quantum dot light-emitting layer, the method comprising the following steps,

[0041] Step 1: Quantum dot solution preparation: Quantum dots are dissolved in n-hexane to prepare a quantum dot solution with a concentration of 30 mg / ml; wherein, the quantum dots are colloidal nano-semiconductor materials composed of III-VI or II-V elements.

[0042] Step 2: Quantum dot ligand stripping: Take 10ml of the quantum dot solution in step 1, add 1ml of electrophile, the electrophile can be benzoyl chloride, and sonicate for 10min;

[0043] Step 3: Redispersion of quantum dots: Add 0.5ml N,N-dimethylformamide to the solution in step 2, purify twice, and prepare quantum dot N,N-dimethylformamide with a concentration of 30mg / ml solution;

[0044] Step 4: Preparation of ligand-stripped quantum dot luminescent layer: spin-coat quantum dot N,N-dimethylformamide solution in step 3 on the hole transport layer, and ann...

Embodiment 3

[0053] A method for preparing a light-emitting diode with a ligand-stripped quantum dot light-emitting layer, the method comprising the following steps,

[0054] Step 1: Quantum dot solution preparation: Quantum dots are dissolved in toluene to prepare a quantum dot solution with a concentration of 40 mg / ml; wherein, the quantum dots are colloidal nano-semiconductor materials composed of III-VI or II-V elements.

[0055] Step 2: Quantum dot ligand stripping: take 10ml of the quantum dot solution in step 1, add 1ml of electrophile, the electrophile can be benzoyl chloride, and sonicate for 10min;

[0056] Step 3: Redispersion of quantum dots: Add 0.5ml N,N-dimethylformamide to the solution in step 2, purify twice, and prepare quantum dot N,N-dimethylformamide with a concentration of 40mg / ml solution;

[0057] Step 4: Preparation of ligand-stripped quantum dot luminescent layer: spin-coat quantum dot N,N-dimethylformamide solution in step 3 on the hole transport layer, and anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com