Production device for preparing radioactive iodine-131 through continuous feeding

A technology for radioactive iodine and production equipment, which is applied in the field of radioisotope preparation, can solve the problems of small processing capacity and inability to continuously feed materials in dry process, so as to reduce unsafe factors, reduce the generation of solid waste, and reduce the dose of personnel exposure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

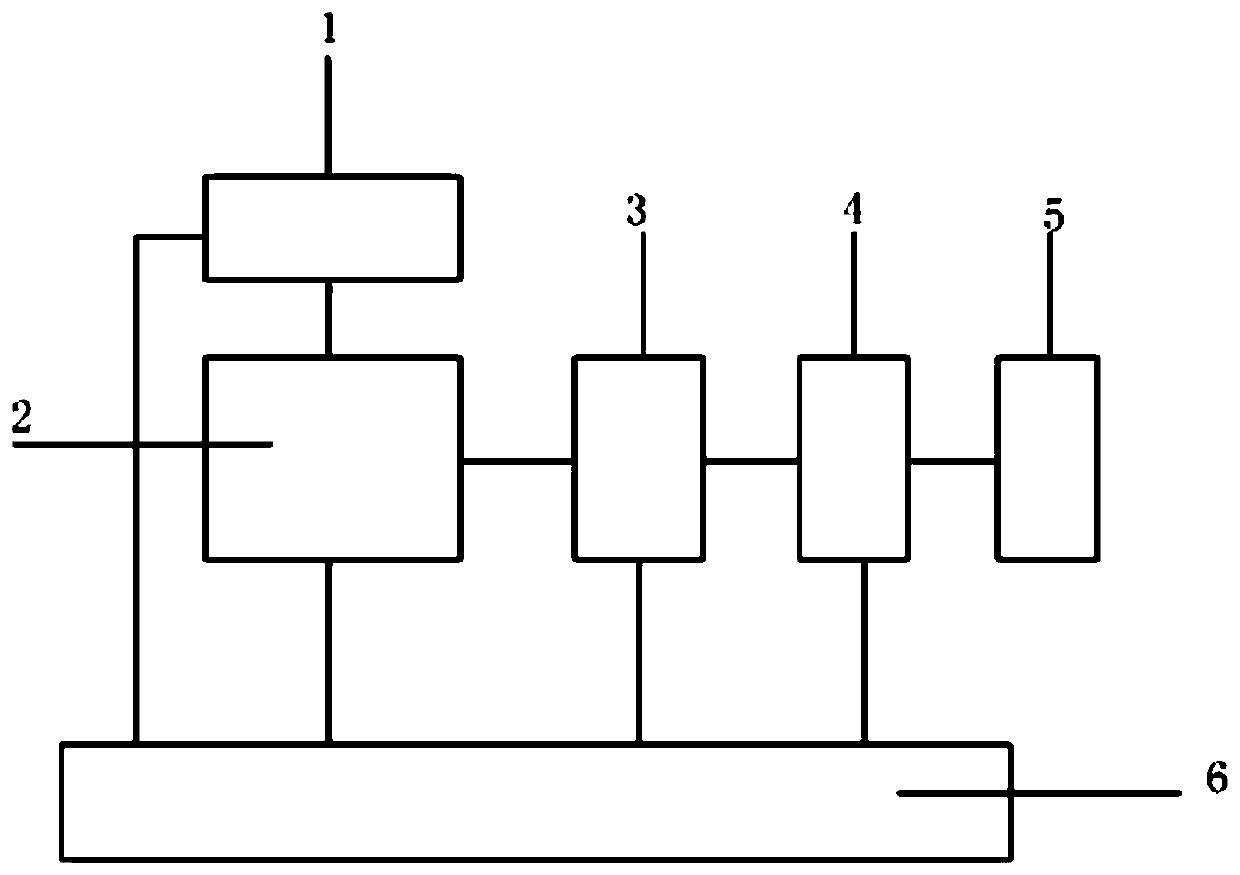

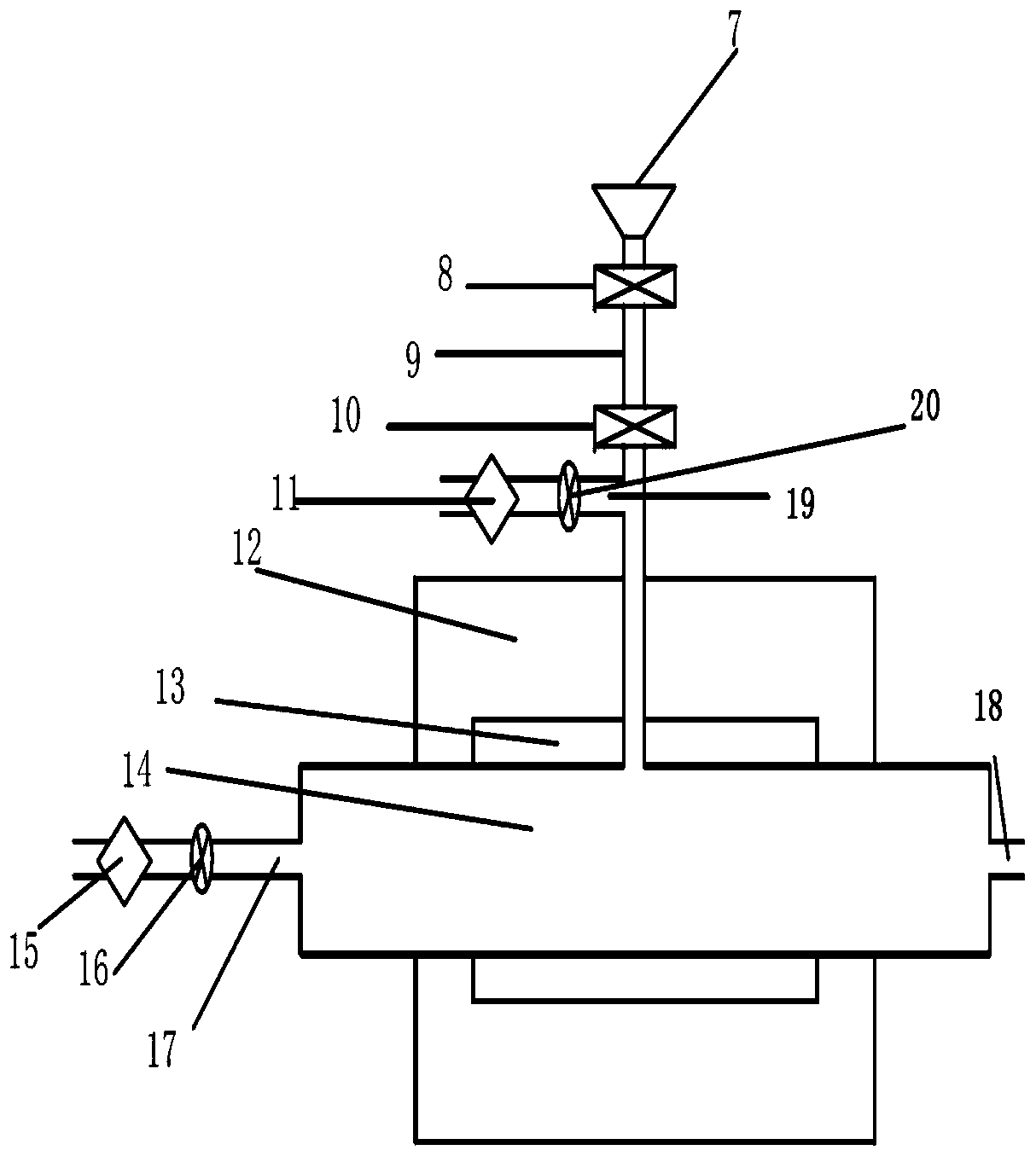

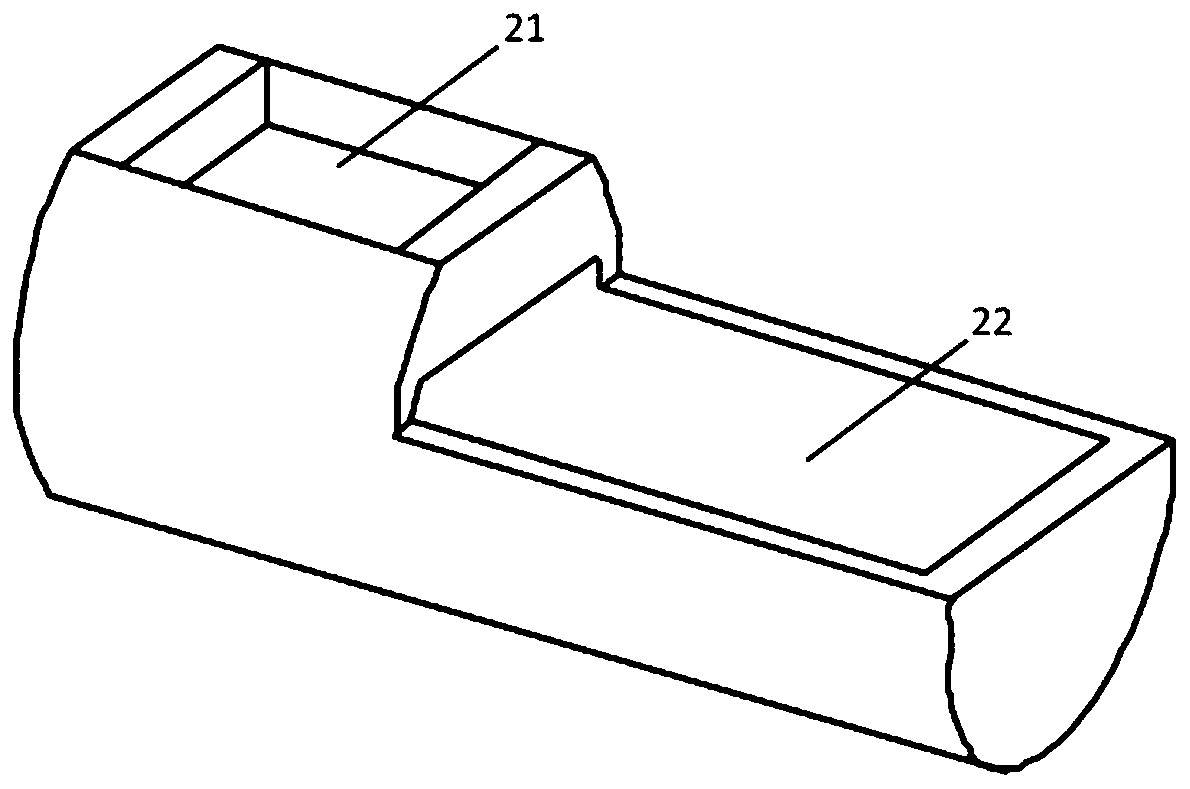

[0035] Such as Figure 1-Figure 3As shown, a production device for preparing radioactive iodine-131 by continuous feeding includes a retort furnace 2, and the retort furnace 2 includes a heating furnace body 12, and the heating furnace body 12 is provided with an insulating layer, a resistance wire 13 and a thermoelectric Even, the heating furnace body 12 is a rectangular parallelepiped, and the heating furnace body 12 is front and rear opening type, that is, the front end and the rear end of the heating furnace body 12 are provided with a furnace cover, and the furnace cover has an automatic switch cover function, and the furnace cover is formed by The controller controls the automatic opening and closing, the resistance wire 13, the thermocouple and the furnace cover are electrically connected to the controller, the heating furnace body 12 is provided with a T-shaped furnace tube 14, and the T-shaped furnace tube 14 includes a large round tube. The two ends of the large roun...

Embodiment 2

[0045] Such as Figure 1-Figure 4 As shown, the present embodiment is based on embodiment 1, the outlet pipe 18 is connected to the tellurium dioxide trap 3, and the tellurium dioxide trap 3 is connected to the absorption device 4; the tellurium dioxide trap 3 Including a housing 24, a heating and heat preservation device is arranged in the housing 24, a tellurium dioxide trapping coil 23 is arranged in the heating and heat preservation device, and the tellurium dioxide trapping coil 23 is a tubular structure, the The tellurium dioxide collection coil 23 is spirally arranged in the casing 24 , and the two ends of the tubular structure communicate with the gas outlet pipe 18 and the absorption device 4 respectively.

[0046] In this embodiment, the working temperature of the heating and heat preservation device is higher than the iodine desublimation temperature and lower than the boiling point of tellurium dioxide. The content of Te impurity in the product is reduced.

[004...

Embodiment 3

[0050] Such as Figure 1-Figure 4 As shown, the present embodiment is based on embodiment 1 or embodiment 2, and the rear end of the absorption device 4 is connected with a tail gas treatment device 5; Sodium hydroxide solution absorbs iodine vapor, and 0.1-5mol / l sodium hydroxide solution is used to absorb tail gas in the second, third and fourth stages of absorption.

[0051] In this embodiment, the tail gas treatment device 5 is an iodine vapor absorption device, which can ensure complete absorption of iodine in the iodine-131 tail gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com