Simple high-carbon aldehyde synthesis catalyst

A carbon aldehyde catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, carbon monoxide reaction preparation, organic chemistry, etc., can solve the problems of not getting rid of the preconditions, and achieve the improvement of disorder and dispersion, selectivity and yield The effect of high efficiency and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

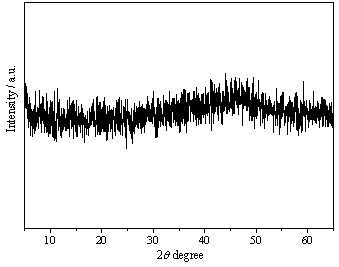

Image

Examples

Embodiment 1

[0023] Weigh 2.3793 g CoCl 2 ·6H 2 O, dissolved in 20 mL deionized water; weigh 2.3769 gNiCl 2 ·6H 2 O, dissolved in 20mL deionized water; mix the two solutions evenly, add 3.5192 g NaH 2 PO 2 40 mL of the solution, stirred for 0.5 h; under stirring, added 3.0264 g NaBH 4 40 mL of the solution, and continue to react for 1 h; centrifuge the obtained suspension, wash the filter cake until neutral, wash it with absolute ethanol three times, and dry it in vacuum at 50 ºC to obtain the catalyst. The mass content of Co is 18%, the mass content of Ni is 18%, the mass content of P is 38%, and the mass content of B is 26%.

[0024] Evaluation of Catalytic Activity for Synthesis of 1-Nonanal: Reaction Gas Composition of CO50% and H 2 50%, the reaction temperature is 130 ºC, the reaction pressure is 5 MPa, the stirring speed is 1200 r.p.m, and the reaction time is 4 h. The results are shown in Table 1.

Embodiment 2

[0026] Weigh 2.3793 g CoCl 2 ·6H 2 O, dissolved in 20 mL deionized water; weigh 1.1885 g NiCl 2 ·6H 2 O, dissolved in 10mL deionized water; mix the two solutions evenly, add 2.6394 g NaH 2 PO 2 30 mL of the solution, stirred for 0.5 h; under stirring, add 2.2698 g NaBH 4 The solution was 30 mL, and the reaction was continued for 1 h; the obtained suspension was centrifuged, and the filter cake was washed to neutrality, then washed three times with absolute ethanol, and vacuum-dried at 50 ºC to obtain the catalyst. The mass content of Co is 24%, the mass content of Ni is 12%, the mass content of P is 38%, and the mass content of B is 26%. The activity evaluation is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0028] Weigh 2.3793 g CoCl 2 ·6H 2O, dissolved in 20 mL deionized water; weigh 3.56535 gNiCl 2 ·6H 2 O, dissolved in 30mL deionized water; mix the two solutions evenly, add 4.399 g NaH 2 PO 2 50 mL of the solution, stirred for 0.5 h; under stirring, added 3.783 g NaBH 4 The solution was 50 mL, and the reaction was continued for 1 h; the obtained suspension was centrifuged, and the filter cake was washed to neutrality, then washed three times with absolute ethanol, and vacuum-dried at 50 ºC to obtain the catalyst. The mass content of Co is 14%, the mass content of Ni is 22%, the mass content of P is 38%, and the mass content of B is 26%. The activity evaluation is the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com