The preparation method of stannous fluoride

A technology of stannous fluoride and barium fluoride, which is applied in the field of preparation of fine chemicals, can solve the problems of high production cost, inflammability and explosion, and complicated process flow, and achieves favorable storage and stability, mild reaction conditions, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

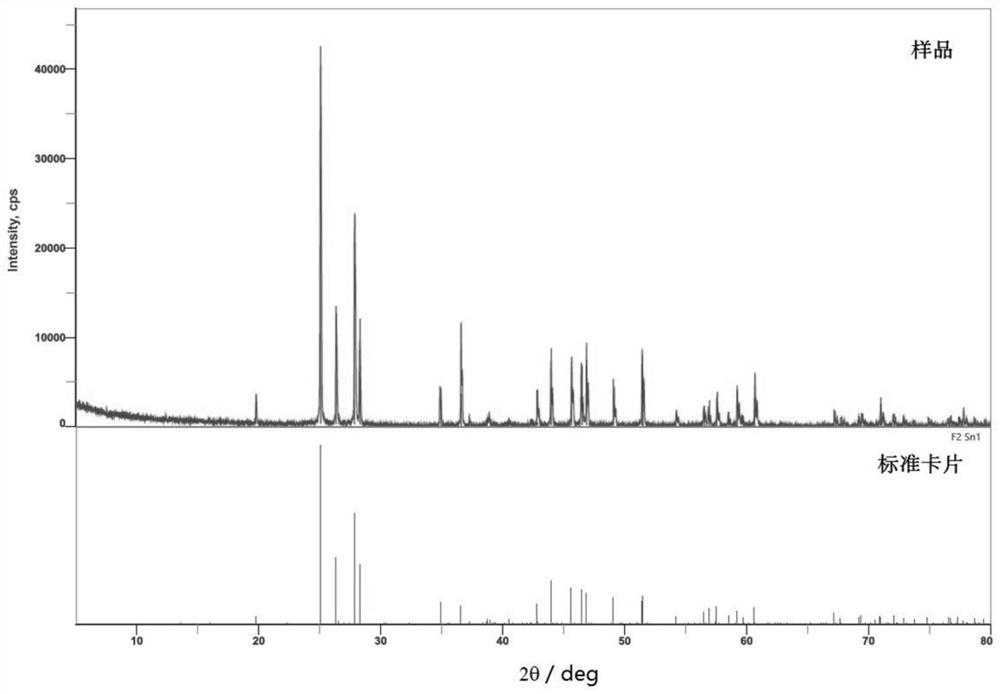

Image

Examples

Embodiment 1

[0034] (1) add 200g mass concentration 10% hydrofluoric acid aqueous solution in reactor, open and stir, add 60g stannous sulfate solid in above-mentioned hydrofluoric acid aqueous solution, dissolve completely, obtain the hydrofluoric acid solution of stannous sulfate. Starting from the addition of stannous sulfate, nitrogen gas is passed into the hydrofluoric acid aqueous solution, and the flow rate is controlled so that no liquid splashes out.

[0035] (2) Take by weighing 36g barium fluoride and join in the stannous sulfate hydrofluoric acid solution in the step (1) with the speed of 15g / min, after adding, continue to react for 10 minutes. During the reaction process, nitrogen gas was continuously passed into the solution, and the flow rate was controlled so that no liquid splashed out.

[0036] (3) Carry out solid-liquid separation to the solution after step (2) reaction, the obtained filtrate is evaporated and concentrated to crystallization at 80°C, then vacuum-dried at...

Embodiment 2

[0040] (1) add the hydrofluoric acid aqueous solution of 500g mass concentration 10% in reactor, open and stir, add 125g stannous sulfate solid in above-mentioned hydrofluoric acid aqueous solution, dissolve and obtain the hydrofluoric acid solution of stannous sulfate completely. Starting from the addition of stannous sulfate, nitrogen gas is passed into the hydrofluoric acid aqueous solution, and the flow rate is controlled so that no liquid splashes out.

[0041] (2) Take by weighing 102g barium fluoride and join in the hydrofluoric acid solution of tin protosulfate in the step (1) with the speed of 25g / min, after feeding finishes, continue reaction 30 minutes. During the reaction process, nitrogen gas was continuously passed into the solution, and the flow rate was controlled so that no liquid splashed out.

[0042] (3) The solution after the reaction in step (2) is subjected to solid-liquid separation, and the obtained filtrate is evaporated and concentrated to crystalliz...

Embodiment 3

[0045] (1) add the hydrofluoric acid aqueous solution of 2000g mass concentration 5% in reactor, open and stir, add 400g stannous sulfate solid in above-mentioned hydrofluoric acid aqueous solution, dissolve and obtain the hydrofluoric acid solution of stannous sulfate completely. Starting from the addition of stannous sulfate, nitrogen gas is passed into the hydrofluoric acid aqueous solution, and the flow rate is controlled so that no liquid splashes out.

[0046] (2) Take by weighing 360g barium fluoride and join in the hydrofluoric acid solution of tin protosulfate in the step (1) with the speed of 30g / min, after feeding finishes, continue reaction 30 minutes. During the reaction process, nitrogen gas was continuously passed into the solution, and the flow rate was controlled so that no liquid splashed out.

[0047](3) The solution after the reaction in step (2) is subjected to solid-liquid separation, and the obtained filtrate is evaporated and concentrated to crystalliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com